E6582175

C-11

3

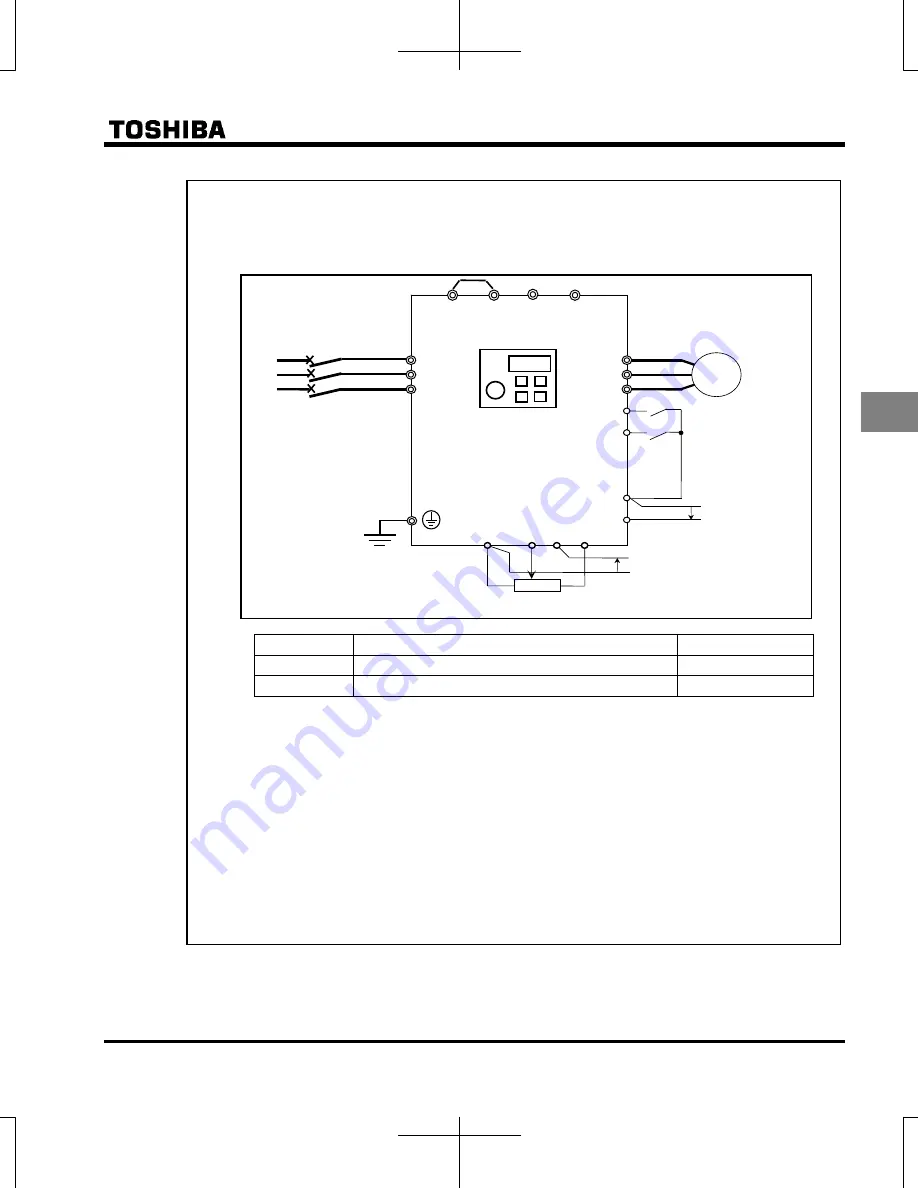

Operation Command: External Signal

Frequency Command: External Analog Signal

(1) Wiring

(2) Parameter setting

Title

Function

Setting value

Command mode selection

0

Frequency setting mode selection 1

1

,

2

or

8

(3) Operation

Run/stop: ON/OFF input to F-CC, R-CC. (with sink logic)

F is for forward run signal and R is for reverse run signal (default setting)

Frequency setting: VIA: Input 0

+10V

(external potentiometer), VIB: Input 0

+10V (or -10

+10Vdc) or

VIC: 4(0)

20mA to set the frequency.

Set the selection of VIA, VIB or VIC in parameter

.

VIA :

=

VIB :

=

VIC :

=

Refer to section 7.3 for the setting of analog input characteristics.

*1: Single-phase models are R/L1 and S/L2/N.

Ex.4

Motor

M

F

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

Forward signal

R

Reverse signal

MCCB

CC

VIC

Common

Current signal:

4(0)

20mA

CC

VIB PP

Voltage signal: 0

+10V

External potentiometer

(Otherwise, input voltage signal between the terminals VIA-CC.)

PB

PA/+

PO

PC/-

*1

VIA

(or -10

+10Vdc)

Summary of Contents for TOSVERT VF-S15 series

Page 394: ......