Q9 Plus ASD Installation and Operation Manual

255

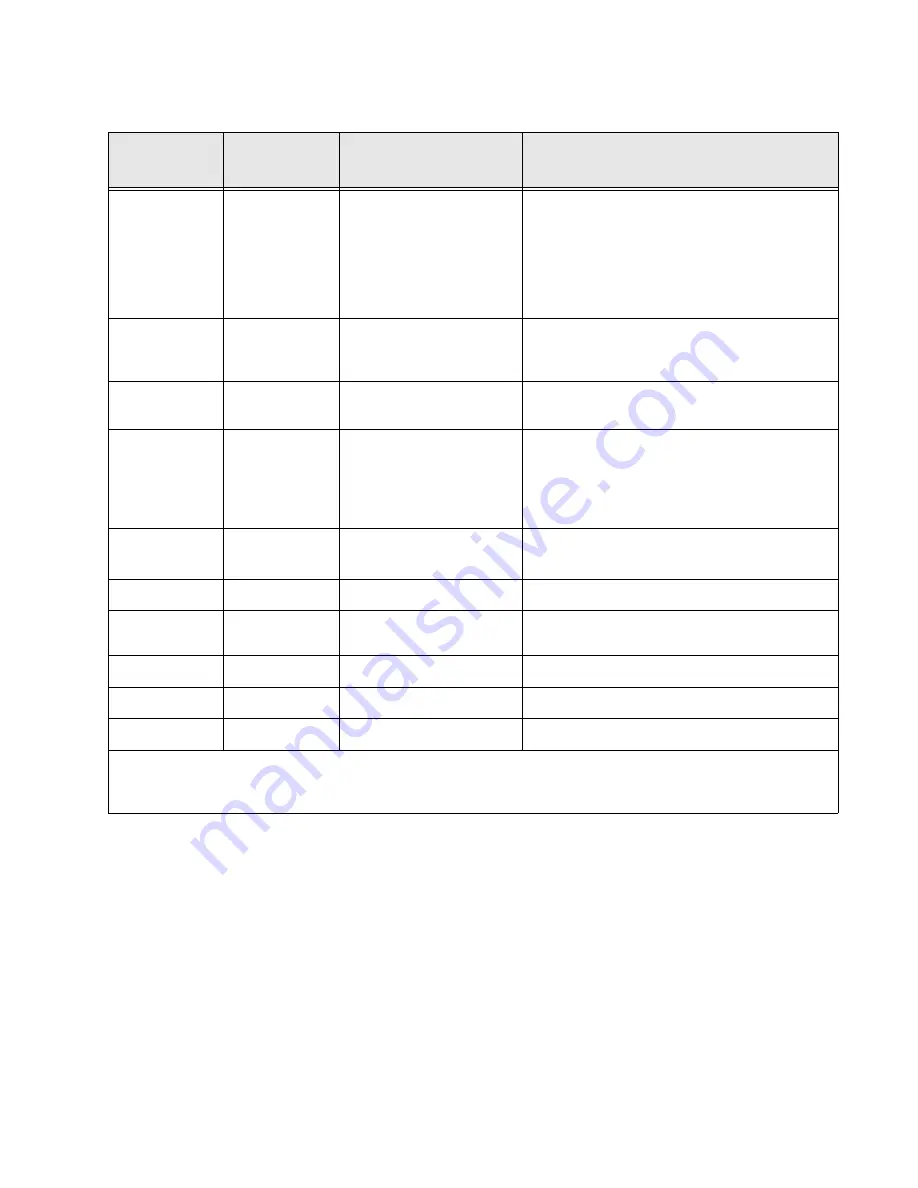

E-13

Over-Speed

Speed Error (Over-Speed).

• Result of a motor speed that is greater than the

commanded speed when using an encoder for

speed control.

• Improper encoder connection or setup

information.

• Defective encoder.

OT

Over-Torque

Over-Torque.

• Output torque requirement in excess of the

F616

or

F617

settings for a time longer than the

F618

setting.

OP1

Over-Voltage

Acc

Over-Voltage During

Acceleration.

• Motor is running during restart.

OP2

Over-Voltage

Dec

Over-Voltage During

Deceleration.

• Deceleration time is too short.

• Stall prevention is disabled.

• 3-phase input voltage is out of specification.

• Input reactance is required.

OP3

Over-Voltage

Run

Over-Voltage During Fixed

Speed Operation.

• Load fluctuations.

• 3-phase input voltage out of specification.

E-21

Stack Err

Stack Overflow Error.

• Service call is required.

SOUT

Step-Out (PM)

Step-Out (For PM Motors

Only).

• Service call is required.

OCA1

U-Phase OC

U-Phase Over-Current.

• Low impedance at the U/T1 phase.

OCA2

V-Phase OC

V-Phase Over-Current.

• Low impedance at the V/T2 phase.

OCA3

W-Phase OC

W-Phase Over-Current.

• Low impedance at the W/T3 phase.

Note:

The event that caused the trip(s) must be corrected or must decrease to less than the threshold value

required to cause the trip to allow for a Reset to be recognized. In the event of multiple active trips, the

trip displayed will remain until all faults are corrected and cleared.

Table 19. Fault Codes (Continued)

LED

Screen

LCD

Screen

Fault Description

Possible Cause

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com