DISASSEMBLY INSTRUCTIONS

B2-2

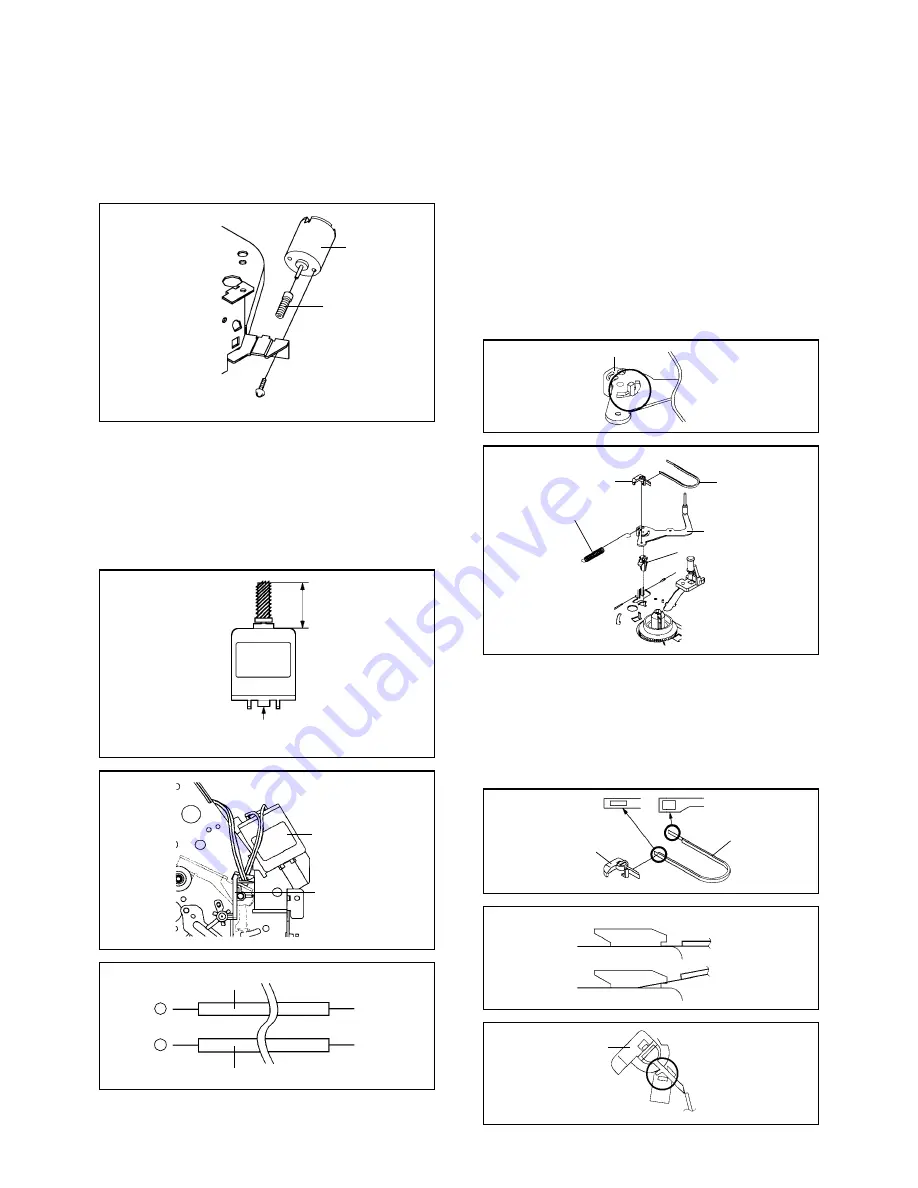

2-6: LOADING MOTOR/WORM (Refer to Fig. 2-6-A)

Remove the screw

1

.

Remove the Loading Motor.

Remove the Worm.

1.

2.

3.

Fig. 2-6-A

• Screw Torque: 3

±

0.5kgf•cm

Loading Motor

1

Main Chassis

Worm

2-7: TENSION ASS'Y (Refer to Fig. 2-7-B)

Turn the Pinch Roller Cam clockwise so that the

Tension Holder hook is set to the position of Fig. 2-7-A

to move the Tension Arm Ass'y.

Remove the Tension Spring.

Unlock the 2 supports

1

and remove the Tension

Band.

Unlock the support

2

and remove the Tension Arm

Ass'y.

Unlock the support

3

and remove the Tension

Connect.

Float the hook

4

and turn it clockwise then remove the

Tension Holder.

1.

2.

3.

4.

5.

6.

NOTE

1.

2.

3.

In case of the Worm installation, check if the value of

the Fig. 2-6-B is correct.

In case of the Loading Motor installation, hook the wire

on the Cassette Opener as shown Fig. 2-6-C.

When installing the wires between Capstan DD Unit

and Loading Motor, connect them correctly as shown

Fig. 2-6-D.

Loading Motor

Capstan DD Unit

-

+

L2

L1

Pink

Fig. 2-6-D

White

Fig. 2-7-A

Tension Arm Ass'y

Fig. 2-7-B

Fig. 2-7-D

Tension Band

Tension Spring

1

2

4

Tension Band

Tension Arm Ass'y

3

1

Tension Holder

Tension Connect

NOTE

1.

2.

3.

In case of the Tension Band installation, note the

direction of the installation. (Refer to Fig. 2-7-C)

In case of the Tension Band installation, install correctly

as Fig. 2-7-D.

In case of the Tension Connect installation, install as

the circled section of Fig. 2-7-E.

Tension Band

Tension Connect

Tension Connect

[OK]

[NG]

Fig. 2-7-E

Tension Connect

Main Chassis

Fig. 2-7-C

Tension Band

Tension Connect

Fig. 2-6-B

19.2

±

0.1mm

Safety surface for pressing

of the insert.

Fig. 2-6-C

Loading Motor

Cassette Opener