Alignment and Adjustment

Toshiba

5-7

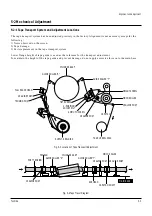

(3) Check Transitional Operation from RPS to Play

Check transition from RPS mode to play mode :

Using a pre-recorded SP tape, make sure the entry

side of envelope comes to an appropriate steady state

within 3 seconds (as shown in Fig. 5-12).

If the envelope waveform does not reach specified

peak-to peak amplitude within 3 seconds, adjust as

follows :

1) Make sure there is no gap between the supply

roller lower flange and the tape.

If there is a gap, adjust the supply guide roller

again.

2) Change operation mode from the RPS to the play

mode (again) and make sure the entry side of

envelope rises within 3 second.

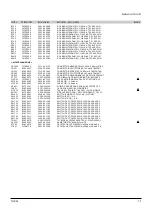

ENTRANCE SIDE ENVELOPE

Fig. 5-12 Video Envelope Rising when Operation mode Changes

from RPS to Play Mode

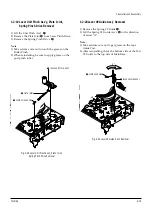

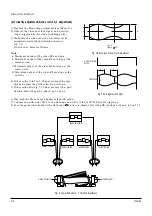

(4) Envelope Check

1) Make recordings on T-120 (E-120) and T-160

(E-180) tape.

Make sure the playback output envelope meets the

specification as shown in Fig. 5-13.

2) Play back a self recorded tape (recording made on

the unit using with T-120 (E-120).

The video envelope should meet the specification

as shown in Fig. 5-13.

In SP mode, (A) should equal (B).

If the head gap is wide, upper cylinder should be

checked.

A

B

Fig. 5-13 Envelope Output and Output Level

(5) Tape Wrinkle Check

1) Run the T-160 (E-180) tape in the playback, FPS,

RPS and Pause modes and observe tape wrinkle at

each guide.

2) If excessive tape wrinkle is observed, perform the

following adjustments in Playback mode :

◆

Tape wrinkle at the guide roller S, T section :

Linearity adjustment.

◆

Tape wrinkle at tape guide flange :

ACE head assembly coarse adjustment.

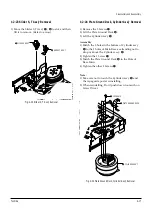

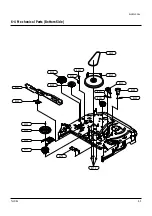

5-2-3 Reel Torque

1) The rotation of the capstan motor causes the

Holder Clutch Ass’y to rotate through the Belt

Pulley.

2) The spring wrap PLAY/REV of holder clutch ass’y

drives the disk reel S, T through gear idle by rota-

tion of gear center ass’y.

3) Brake is operated by slider cam at FF/REW mode.

4) Transportation of accurate driving force is done by

gears. (Gear Center Ass’y)

Note : If the spec. does not meet the followings speci-

fications, replace the holder clutch ass’y and then

recheck.

MODE

TORQUE g/cm

GAUGE

PB

42 ± 11

Cassette Torquemeter

RPS

145 ± 30

Cassette Torquemeter

<Table 5-1>