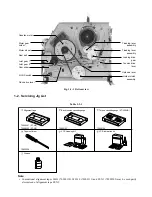

1-4. Mechanism Check Method

If the abnormal condition is caused by the mechanism

itself, analyze the cause according to the following

procedures.

1-4-1. External Appearance Check

1. Check whether there are foreign matters or not inside

the VCR.

2. Check whether the cylinder and the guides for tape

transport system are contaminated.

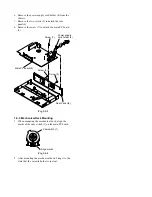

1-4-2. Motor and Sensor System Check

Check whether some abnormalities are found in the

motor or the sensor system (including control circuits)

according to the flowchart.

1-4-3. Abnormality Analysis by Self-check Function

The unit has a self-check function. The self-check

function works as a system which stored some abnormal

condition. So, use this function to try to analyze the

cause(s).

For the data display method and the content of the data,

refer to self-check function in item 1-8.

After repairing, initialize the data by pressing the button

while displaying the abnormal mode.

Notes:

• Abnormal data is displayed only when the first

abnormal condition occurs, and is not displayed in

the second time and after. Accordingly, the claim

from customers and the actual data displayed may be

different.

• The data is stored only when the power turns off after

occurring the abnormality condition(s). The data is

not stored when the unit operation is recovered by

the microprocessor.

The typical examples in abnormal condition are shown

below.

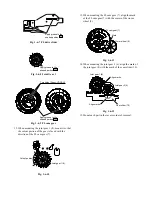

Does the

capstan motor rotate

after loading a cassette

holder without

a cassette?

Does the

T reel rotate with the

operation above?

Does the

loading motor and the

worm wheel rotate without

a cassette after turning

the power ON?

Does the

FL cam gear rotate

approximate 15 degrees

clockwise with the operation

above and return

immediately?

Does the

VCR stop at

the playback position

after detecting the tape remain

with the cassette with

a safety tab

inserted?

Loading motor is

abnormal.

Reel sensor system is

abnormal when the

cassette is ejected

without rewinding tape

or stopped in the way

of unloading operation.

When the mechanical

operation is not

normal, the cam

switch is defective.

Tape start sensor is

abnormal.

Capstan motor is

abnormal.

Reel belt and reel system

are abnormal.

Motor and sensor system

are normal.

YES

NO

NO

NO

NO

NO

YES

YES

YES

YES

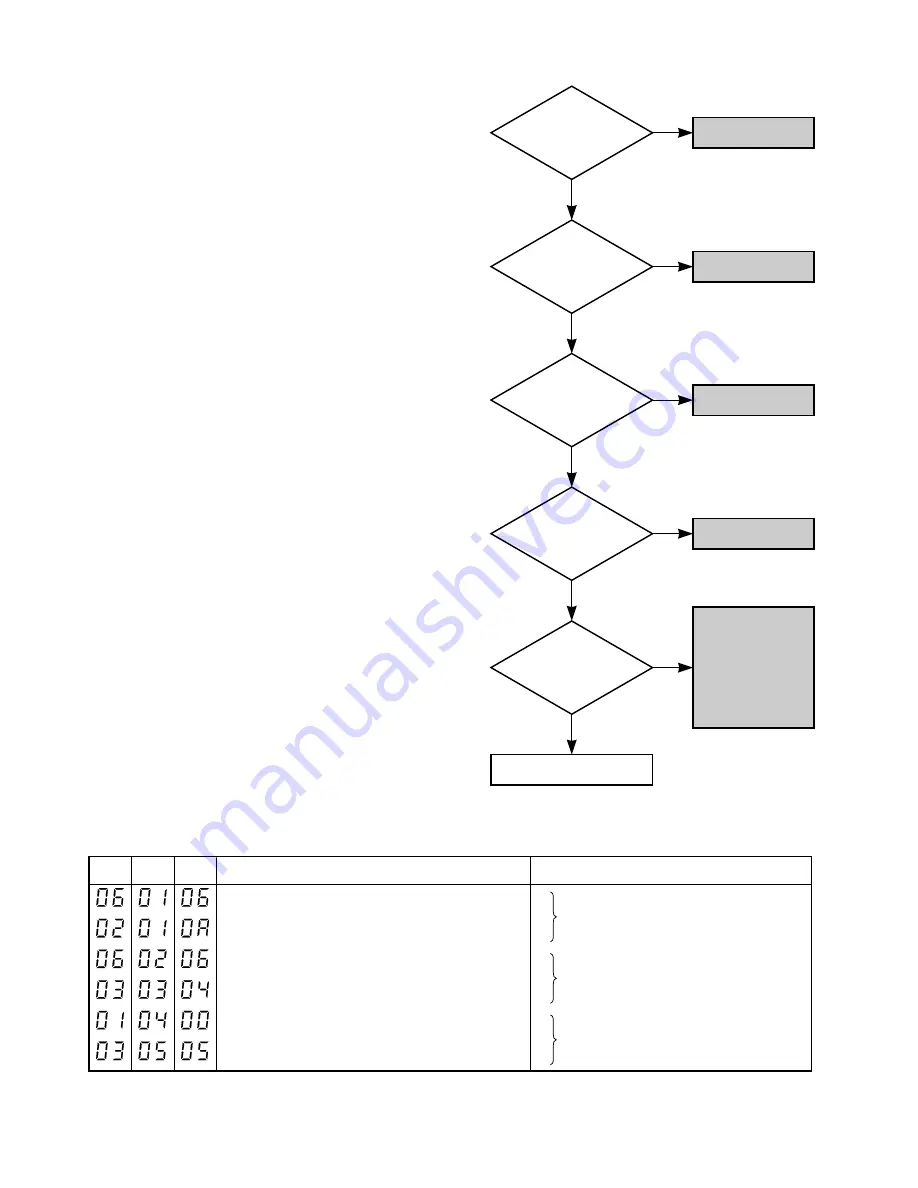

Fig. 1-4-1

Table 1-4-1

A: System control mode, B: Abnormality No., C: Mechanical position when an abnormality occurs.

Abnormal condition

Cylinder stops at playback position during

playback the tape.

Cylinder stops at FF/REW position during

rewind the tape.

T reel sensor is abnormal at playback position

during playback the tape.

S reel sensor is abnormal at review/playback

position during REVIEW/PLAYBACK the tape.

Cassette-in and out operation cannot be performed.

Mode shift cannot be performed during shifting to

REVIEW/PLAYBACK mode.

Check item

Check the cylinder motor.

Check if the cylinder and tape transport

guide are clogged.

Check the capstan motor.

Refer to the cases 2 and 3 described on

the table "Defective analyzing table 1-4-2".

Refer to the case 1 described on the

table "Defective analyzing table 1-4-2".

A

B

C