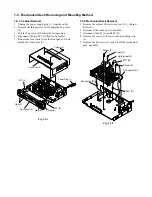

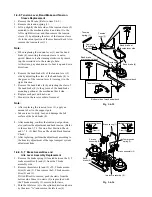

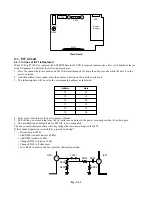

<Replacement>

1. Remove the slip ring assembly. (Refer to item 1-6-17.)

2. Remove the head cleaner assembly. (Refer to item 1-

6-16.)

3. Remove the FPC (1) from the main PC Board.

4. Remove the screw (2) fixing the slip ring bracket (3)

and remove the slip ring bracket (3).

5. Remove the cylinder holding plates (4), (5) and (6).

(Refer to item 1-6-19.)

6. Remove the head assembly (cylinder) (7).

7. Replace the head assembly (cylinder) (7) with new

one.

8. When mounting, take care of the direction of the

head assembly (cylinder) (7).

9. Remount the head assembly (cylinder) (7) in the

reverse order of removal. Fix it pressing slightly in

the direction shown by the arrow A for the cylinder

holding plate (4) pressing slightly in the direction

shown by the arrow B, and the cylinder holding plate

(4) pressing slightly in the direction shown by the

arrow C for the cylinder holding plate (6). (Tighten-

ing torque : 294 to 392 mN•m (3 to 4kg•cm))

Fix the slip ring bracket (1) with the screw (2) after

adjusting the boss of the mechanical deck to the boss

hole of the slip ring bracket (3). (Tightening torque :

294 to 392 mN•m (3 to 4kg•cm))

Slip ring assembly

FPC (1)

Head cleaner assembly

Slip ring bracket (3)

Cylinder

holding

plate (4)

Head

assembly (7)

(Cylinder)

Cylinder pin

Cylinder holding plate (5)

A

B

Cylinder

holding

plate (6)

C

Screw (2)

Fig. 1-6-47

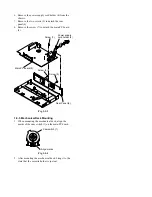

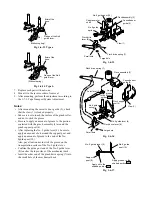

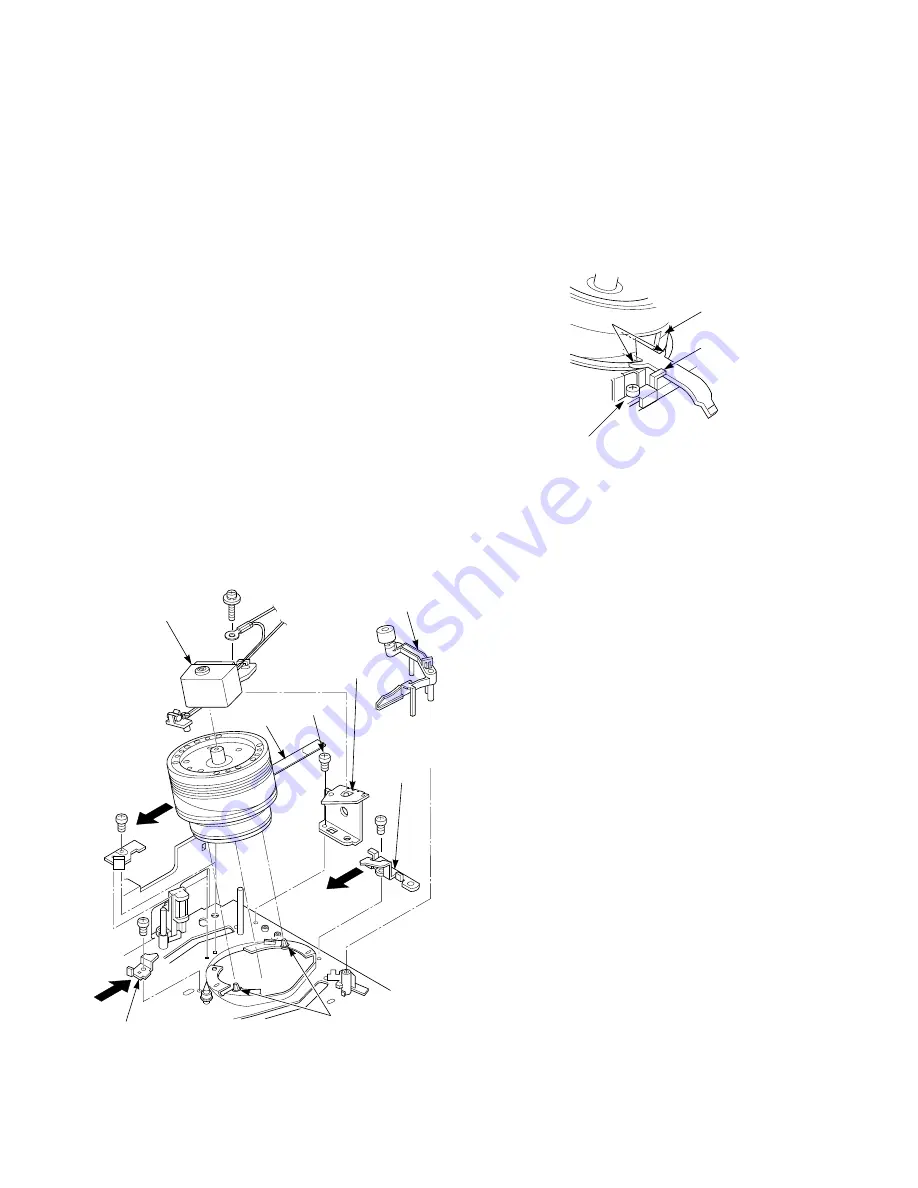

Notes:

• When remounting the cylinder holding plate (4),

after confirming that the FPC (1) is hooked at the

groove on the lower head assembly properly, insert

the FPC (1) under the tip of the cylinder holding

plate.

However, this is not applied for the type which has

no cylinder window.

• When replacing, take much care not to touch the

video head directly and damage the cylinder.

Hook FPC on the groove.

(2 points)

Head assembly (9)

(Cylinder)

Cylinder holding plate (4)

FPC (3)

Insert FPC under

the cylinder tip.

Cylinder window

Fig. 1-6-48

9. After mounting, perform the adjustment according to

the 1-7-3. Tape Transportation System Adjustment.

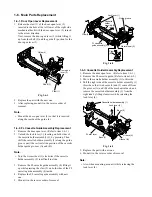

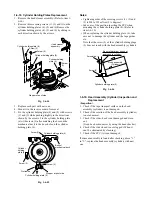

1-6-20. Capstan Motor Assembly and Reel Belt

Replacement

1. Remove the reel belt (1).

2. Remove three screws (2) from the front side of the

mechanical deck while keeping the capstan motor

assembly (3) of the mechanical deck bottom side.

3. Replace the capstan motor with new one.

4. Insert the capstan motor assembly (2) from the

bottom side of the mechanical deck while taking care

not to hit or damage the capstan motor shaft (4) and

whole motor, so that the positioning hole of the

mechanical deck and the positioning hole of the

capstan motor assembly fit.

5. Fix the capstan motor assembly (3) with three screws

(2) by tightening evenly while keeping the capstan

motor assembly (3) of the mechanical deck bottom

side.

At this time, adjust it so that the hole of the mechani-

cal deck and the positioning hole of the capstan

motor is fit.