1-7-3. Tape Transport System Adjustment

The tape transport system has been precisely adjusted in

the factory, so only when some defective phenomenon

occurs such as noise observed on the screen and tape

damage, or when replacing the portion shown on the

adjustment procedures of the tape transport system,

adjustment and check are necessary.

Electrical signal output terminal required for adjustment

differs depending upon the models. Refer to the test

point location in the Electrical Adjustment Section.

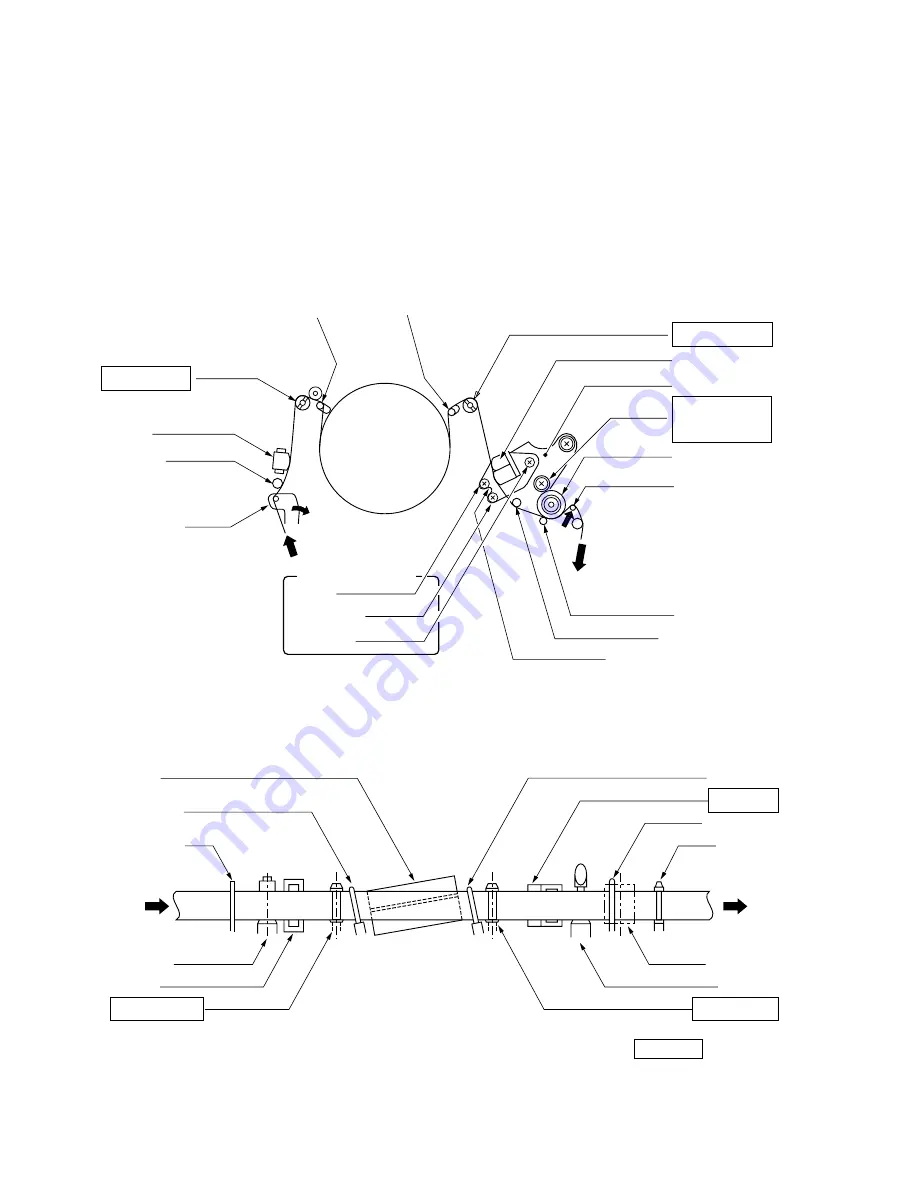

(1) Location of Tape Transport Adjustment

<Adjustment Reference>

Lower flange height of No.8 guide is used as the basic

reference for the transport adjustment. To keep height of

the No.8 guide, do not apply excessive force onto the

main base to prevent the main base from deformation.

Pinch roller

S guide roller

S slant guide

T slant guide

T guide roller

FE head

No.3 guide

Tension lever

& tension post

REVIEW (Released

at FF/REW mode)

ACE head

No.8 guide

ACE head position adjusting slit

(Insert a slot-type screwdriver.)

Tilt

Azimuth

Height

ACE adjusting screw

Capstan

No.9 guide (Pulled

out at REVIEW mode)

Cylinder

ACE main base

ACE

head position

securing screw

Fig. 1-7-2

FE head

Pinch roller

No.8 guide

T guide roller

S guide roller

ACE head

No.9 guide

Capstan

T slant guide

Cylinder

Tension post

No.3 guide

S slant guide

: Adjusting portion

Fig. 1-7-3