– 52 –

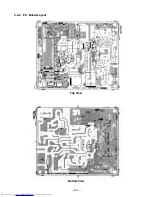

9-4-1. How to Check the P.C. Board

(1) Operating precautions

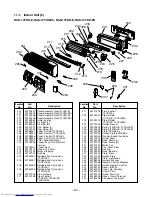

1) When removing the front panel or the P.C.

board, be sure to shut off the power supply.

2) When removing the P.C. board, hold the edge

of the P.C. board and do not apply force to the

parts.

3) When connecting or disconnecting the con-

nectors on the P.C. board, hold the whole

housing. Do not pull at the lead wire.

(

2) Inspection procedures

1) When a P.C. board is judged to be defective,

check for disconnection, burning, or discolora-

tion of the copper foil pattern or this P.C.

board.

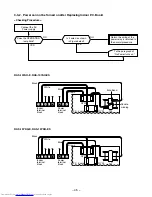

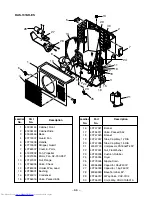

2) The P.C. board consists of the following 2

parts

a. Main P.C. board part:

Power relay, indoor fan motor drive circuit

and control circuit, C.P.U. and peripheral

circuits, buzzer drive circuit and buzzer.

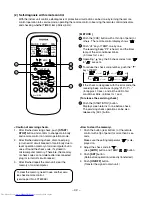

b. Infrared rays receive and indication

parts:

Infrared rays receive unit and LED.