7

Technical Information

Service Manual

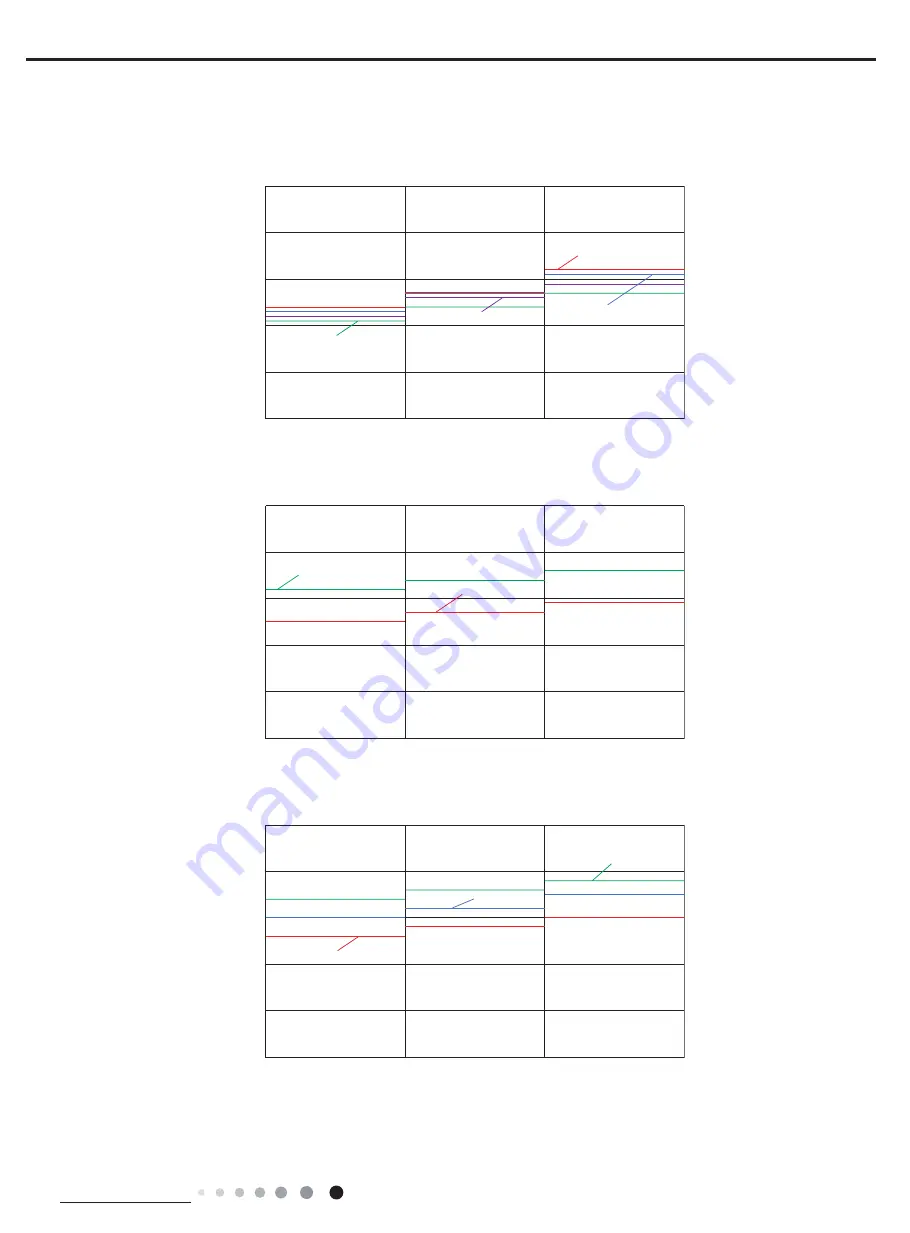

2.2 Noise Criteria Curve Tables for Both Models

Duct Type

0

Middle

Low

High

20

30

50

60

Noice/dB(A)

40

24K

18K

12K

09K

Cassette

0

Middle

Low

High

20

30

50

60

Noice/dB(A)

40

12

、

18K(Compact Panel)

24K

Floor ceiling type

0

Middle

Low

High

20

30

50

60

Noice/dB(A)

40

09

、

12K

18K

24K

Summary of Contents for TM09HEDI

Page 1: ...Service Manual ...

Page 11: ...9 Technical Information Service Manual 3 Outline Dimension Diagram ...

Page 12: ...10 Technical Information Service Manual ...

Page 13: ...11 Technical Information Service Manual 4 Refrigerant System Diagram ...

Page 41: ...39 Installation and Maintenance Service Manual ...

Page 42: ...40 Installation and Maintenance Service Manual 12 18K ...

Page 43: ...41 Installation and Maintenance Service Manual ...

Page 44: ...42 Installation and Maintenance Service Manual ...

Page 45: ...43 Installation and Maintenance Service Manual ...

Page 46: ...44 Installation and Maintenance Service Manual ...

Page 47: ...45 Installation and Maintenance Service Manual ...

Page 48: ...46 Installation and Maintenance Service Manual ...

Page 49: ...47 Installation and Maintenance Service Manual ...

Page 50: ...48 Installation and Maintenance Service Manual 9 Maintenance 9 1 Trouble Table ...

Page 51: ...49 Installation and Maintenance Service Manual ...

Page 52: ...50 Installation and Maintenance Service Manual ...

Page 53: ...51 Installation and Maintenance Service Manual ...

Page 54: ...52 Installation and Maintenance Service Manual ...

Page 55: ...53 Installation and Maintenance Service Manual ...

Page 75: ...73 Installation and Maintenance Service Manual ...

Page 76: ...74 Installation and Maintenance Service Manual ...

Page 77: ...75 Installation and Maintenance Service Manual ...

Page 78: ...76 Installation and Maintenance Service Manual ...

Page 79: ...77 Installation and Maintenance Service Manual Floor ceiling type ...

Page 80: ...78 Installation and Maintenance Service Manual ...

Page 81: ...79 Installation and Maintenance Service Manual ...

Page 88: ...JF00304027 ...