- 7 -

•

Wipe off powder coated surfaces with soft, moist rag. Do not clean heater with cleaners that

are combustible or corrosive.

•

Remove debris from the burner to keep it clean and safe for use.

•

Cover the burner unit with the optional protective cover when the heater is not in use.

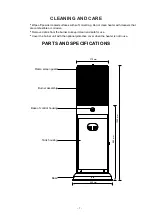

PARTS AND SPECIFICATIONS

1360 mm

880 mm

370 mm

460 mm

Flame screen guard

Burner assembly

Base of control housing

Tank housing

Base

CLEANING AND CARE