16/20

7. MAINTENANCE

7.1.

Safety instructions for the repair of the product

Some of the maintenance operations should only be carried out by professional

technicians.

If you require this information and the maintenance steps, please contact your

dealer.

• Do not attempt to repair the product unless you are trained and authorised to

do so.

• Repairs to the product may only be made by a qualified service technician and

according to the manufacturer’s instructions.

• Bystanders who are not working on the vehicle must keep a minimum distance of

0.5 m from the vehicle.

7.2.

Maintenance schedule

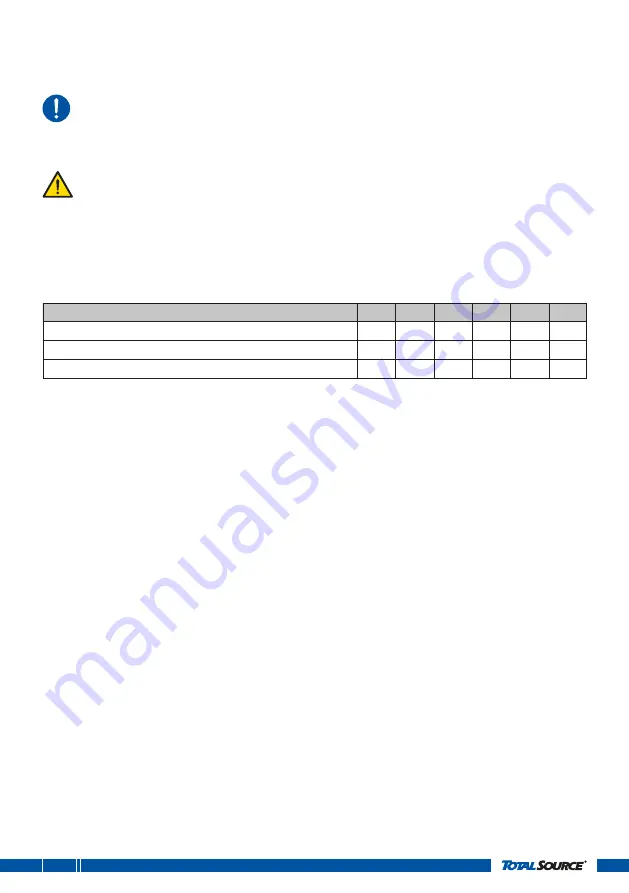

Task

2H

D

W

M

6M

Y

1. Inspect for damage or cracks

2. Cleaning

3. Lubrication

2H: every 2 hours, D: daily, W: weekly, M: monthly, 6M: every 6 months, Y: yearly

7.3.

Maintenance instructions

1. Inspect for damage or cracks

A daily check of the support stands can limit wear to a minimum:

• Ensure that the instruction manual is complete, legible and available for reference.

• Ensure that all decals are legible and in place.

• Check entire machine for: damage, corrosion or cracks in structural components.

This maintenance may be carried out by the operator.

2. Cleaning

• Clean as needed and wipe with an oily cloth.

• When you use a high-pressure cleaner, do not direct the jet onto the bearings and seals,

otherwise the grease will be washed out and the lifespan of the stands will be shortened.

• Never use sandpaper or abrasive material on these surfaces!

This maintenance may be carried out by the operator.