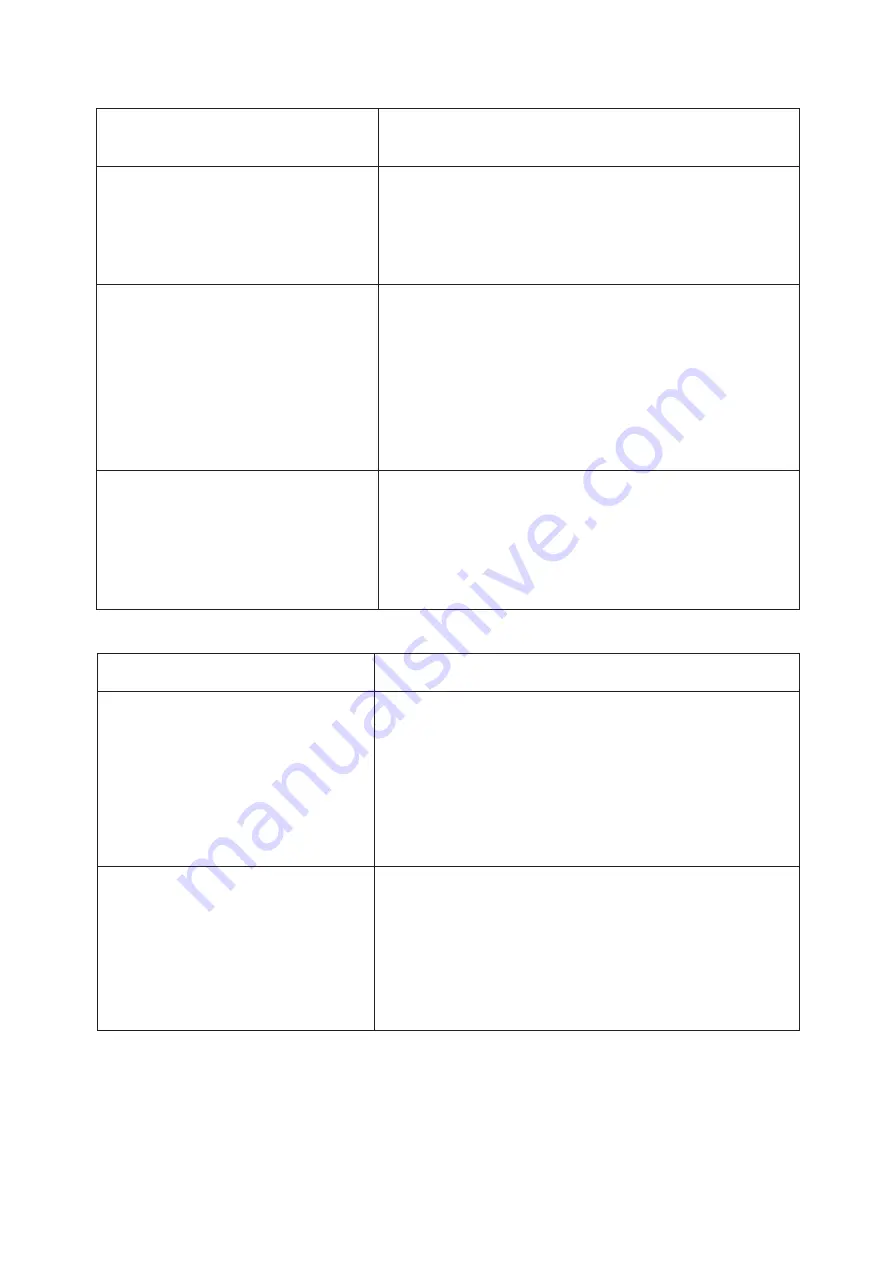

Engine overheats

.

·

Clean cooling fins and fan blades

.

Engine runs

,

rammer does not

tamp

.

·I

nspect clutch for damage

.

Replace if necessary

.

·

Broken connecting rod or crankgear

.

·

Low engine performance

.

Compression loss

.

Engine runs

.

rammer

operation is erratic

.

·

Oil/grease on clutch

.

·

Broken/worn springs

.

·

Soil buildu p on rammin g shoe

.

·

Broken parts in ramming system or crankcase

.

·

Engine operating spee d is too high

.

On machines equipped with

the low oil shutoff switch the

warning lig ht flashes slowly

,

the engine starts but sh uts off

after 10-12 seconds

.

·

Engine oil level is low

.

Add oil to the engin e

.

See

Technical Data for oil quantity and type

.

y

d

e

m

e

R

/

n

o

s

a

e

R

m

o

t

p

m

y

S

/

m

e

l

b

o

r

P

On machines equipped with

the low oil shutoff switch

,

the

engine star ts and conti nues to

run but the low oil warning

light stays on continuo usly

.

·Check the switch for p roper wire connections.

·Swi tch is not functioning properly

.

Replace the

switch.

On machines equipped with

the low oiI shutoff switch the

engine star ts and conti nues to

run

,

but the low oil warning

ligh t did not flash quickly once

.

·Check th e switch for proper wire connections and

grounding.

· Switch is not functioning properly . Replace the

switch

.

26

Summary of Contents for TP880-1

Page 2: ...GASOLINE TAMPING RAMMER TP880 1 TP880 2 TP880 3...

Page 28: ...TP880 1 TP880 2 TP880 3 Exploding view 27...

Page 30: ...TP880 1 TP880 2 TP880 3 Crank case assembly 29...

Page 32: ...TP880 1 TP880 2 TP880 3 Cylinder assembly 31...

Page 34: ...T1217 V04 MADE IN CHINA www totaltools cn TOTAL TOOLS CO LIMITED GASOLINE TAMPING RAMMER...