XSDC 601-01

6.4 Defrosting

In order to ensure ideal cooling, the cooling unit requires adequate defrosting. Therefore the device

has an automatic defrosting cycle. This means that the device will automatically start defrosting every

6 hours. Each individual defrosting cycle will take about 30 minutes.

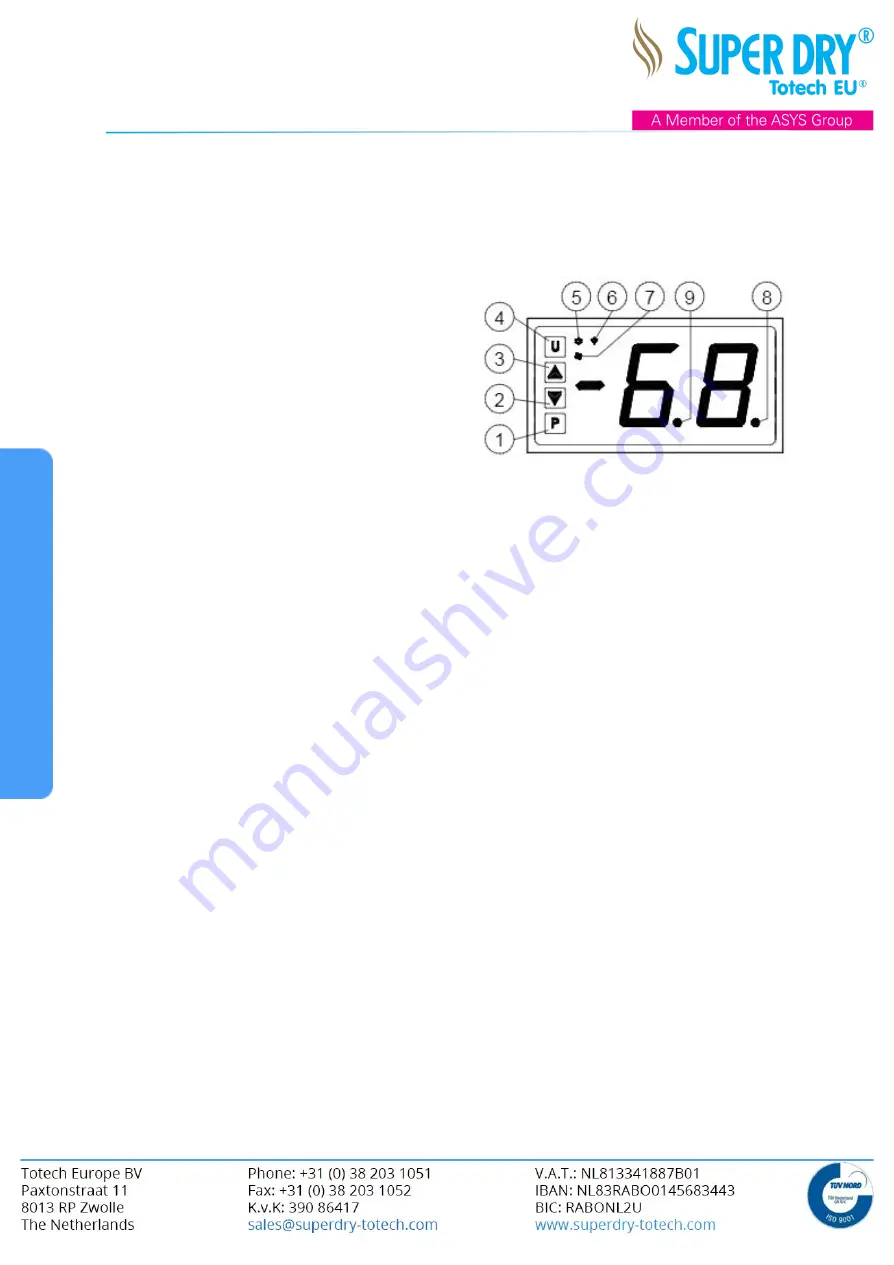

6.5 Front panel description

1 - Key P: Used for setting the setpoint and for

programming the function parameters.

2 - Key DOWN: Used for decreasing the values to be

set and for selecting the parameters.

3 - Key UP: Used for increasing the value to be set,

for selecting parameters and for activating manual

defrosting.

4 - Key U: Used for visualising the temperatures

taken by the cell and evaporator probes (Pr1 and

Pr2).

5 - Led OUT: Indicates the compressor output status on (on), off (off) or inhibited (flashing).

6 - Led DEF: Indicates defrosting in progress (on) or dripping (flashing).

7 - Led FAN: Indicates that the fan is on (on), off (off) or delayed (flashing) after the defrost cycle.

8 - Led SET: Indicates the input in programming mode and the programming level of the parameters.

9 - Stand-By: indicate the Stand-By status.