– 17 –

5. Consumable Parts and AC Adapter

When consumable parts have run out, use those specified in the table below.

Make sure that the AC adapter specified in the table is used.

Use of consumable parts or AC adapter which are not specified in the table may result in dam-

age to the printer, fire or electric shock.

5-1. Thermal Paper Roll

(1) Paper roll specification

Thermal paper

Thickness: 65~85 µm (excluding Mitsubishi HiTec F5041)

Width: 79.5±0.5 mm (57.5±0.5 mm when the paper roller holder is used)

Outer roll diameter: ø83 mm or less

Take up paper roll width: 80

+0.5

-1

mm or (58

+0.5

-1

mm when the paper roller holder is used)

Core outer/inner diameter

Core outer

Core inner

ø18±1 mm

ø12±1 mm

Printed surface:

Outer edge of roll

Tail end handling: Do not use paste or glue to secure the roll paper or its core.

Do not fold the tail end of the paper.

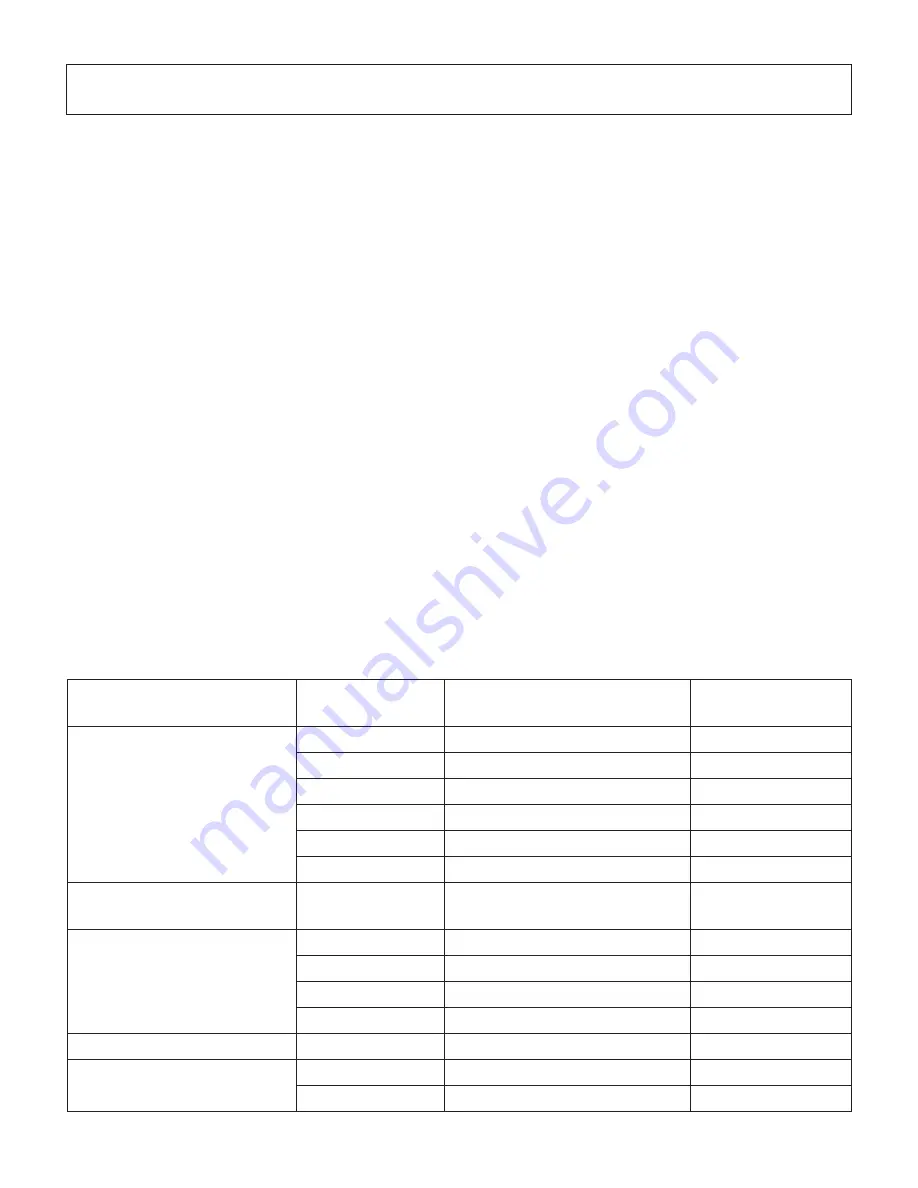

(2) Recommended paper

Manufacturer

Product name

Quality characteristics/Use

Paper thickness

(µm)

Mitsubishi Paper Mills

Limited

P220AG

normal type paper

65 (thickness)

HP220A

high image stability paper

65 (thickness)

HP220AB-1

high image stability paper

75 (thickness)

P220AGB

normal type paper, card ticket

80 (thickness)

PB670

2 color paper: Red & Black

75 (thickness)

PB770

2 color paper: Blue & Black

75 (thickness)

Mitsubishi HiTec Paper

Flensburg GmbH

F5041

normal type paper

60 (thickness)

Oji Paper Co., Ltd.

PD150R

normal type paper

75 (thickness)

PD160R

high image stability paper

65/75 (thickness)

PD750R

2 color paper: Red & Black

75 (thickness)

PD700R

2 color paper: Blue & Black

75 (thickness)

Nippon Paper Industries

TF50KS-E2C

normal type paper

65 (thickness)

Kanzaki Specialty Papers

Inc. (KSP)

P320RB

2 color paper: Red & Black

65 (thickness)

P320BB

2 color paper: Blue & Black

65 (thickness)