20

21

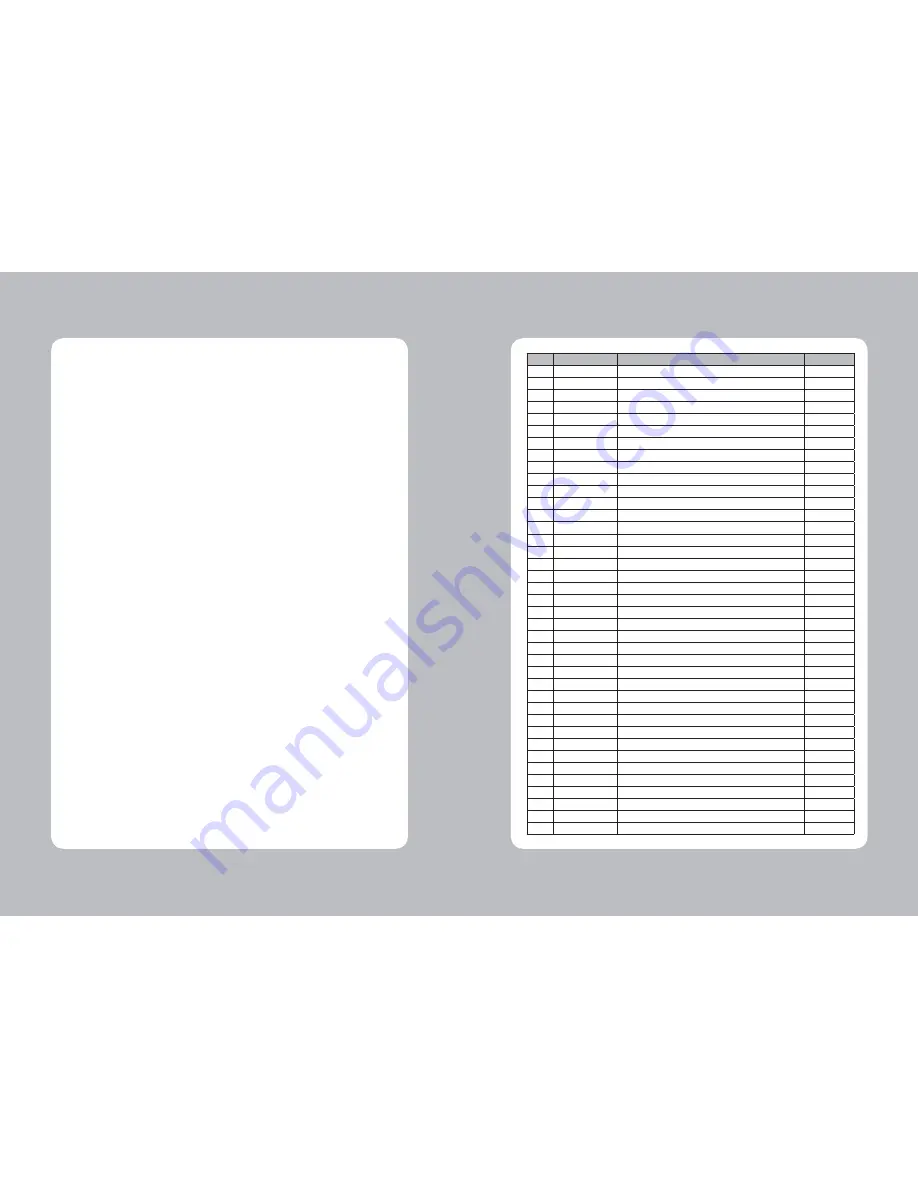

No.

Command

Function

REMARKS

1

HT

Horizontal tab

2

LF

Print and line feed

3

CR

Print and carriage return

4

FF

Print and return to standard mode(in page mode)

5

CAN

Cancel print data in page mode

6

DLE EOT

Real-time status transmission

7

DLE ENQ

Real-time request to printer

8

DLE DC4

Generate pulse at real-time

9

ESC FF

Print data in page mode

10

ESC SP

Set right-side character spacing

11

ESC !

Select print mode(s)

12

ESC $

Set absolute print position

13

ESC %

Select/cancel user-defined character set

14

ESC &

Define user-defined characters

15

ESC *

Set bit-image mode

16

ESC -

Turn underline mode on/off

17

ESC 2

Select default line spacing

18

ESC 3

Set line spacing

19

ESC =

Select peripheral device

20

ESC ?

Cancel user-defined characters

21

ESC @

Initialize printer

22

ESC D

Set horizontal tab positions

23

ESC E

Turn emphasized mode on/off

24

ESC G

Turn double-strike mode on/off

25

ESC J

Print and feed paper using minimum units

26

ESC L

Select page mode

27

ESC M

Select character font

28

ESC R

Select an international character set

29

ESC S

Select standard mode

30

ESC T

Select print direction in page mode

31

ESC V

Turn 90° clockwise rotation mode on/off

32

ESC W

Set printing area in page mode

33

ESC

\

Set relative print position

34

ESC a

Select justification

35

ESC c 3

Select paper sensor(s) to output paper-end signals

36

ESC c 4

Select paper sensor(s) to stop printing

37

ESC c 5

Enable/disable panel buttons

38

ESC d

Print and feed paper n lines

39

ESC p

General pulse

7. Command List

♣

Important!

When connecting or disconnecting the power supply from the printer, be sure that the

following cautions are observed.

(1) Use a power supply (Limited Power Supply) of DC 24V±10% and more than 2.5A.

(2) Be careful about installing the printer in an area where there is noise.

(3) Take the appropriate measure to protect against electrostatic AC line noise, etc.

6-5. Environmental Requirements

(1) Operating

Temperature

5°C to 40°C

Humidity

10% to 90% RH (without condensation)

(2) Transport/Storage (except paper)

Temperature

-20°C to 60°C

Humidity

10% to 90% RH (without condensation)

6-6. Reliability

(1) MCBF

60 million lines (based on an average printing rate of 12.5% with paper

thickness in the range of from 65µm - 75µm)

35 million lines (based on an average printing rate of 12.5% with paper

thickness in the range of from 76µm - 150µm)

(2) Head Life

160Km

(3) Cutter Life

1.5 million cuttings (if the paper thickness is between 65 and 90µm)

6-7. Certification

(1) FCC PART15 CLASS A

(2) UL/cUL (UL 60950-1)

(3) MIC

(4) CE-EMCD (CE-EMCD Class B should use Parallel shield Cable complied with IEEE-1284 standards)

(5) RoHS (TUV)

(6) CCC

Summary of Contents for TP3000

Page 2: ......