BD4603

19

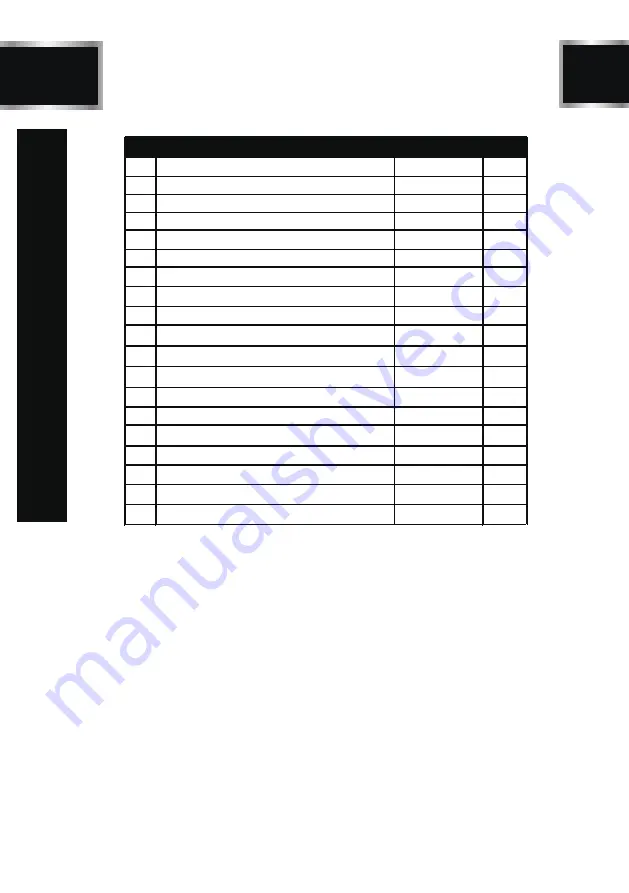

TDS-G200VLDB

PAR

TS LIST

ID Description Size Q’ty

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

Left inner guard cover

Wheel 200x25x15.88 60 grit

Left Fixing tool rest

Left movable tool rest

Lamp (40w)

Flat washer (black) D12

Hex nut (white) M12

Phillips screw (black) M2.5x6

Hex socket set screws (black) M5x6

Flat washer (black) D6

Left spark deflector

Big Flat washer (black) D5

Flat washer (white) D5

Flat washer (black) D6

Wire wheel spacer

Bulb

Wheel dresser

Double fork wrench

Spring washer D6

1

1

1

1

1

1

1

2

1

2

1

2

4

2

1

1

1

1

2