BD4603

11

WARNING

!

OPERA

TION

TLGS625

The operation of any grinder can result in

foreign objects being thrown into your eyes,

which can result in severe eye damage.

Before beginning power tool operation, always

wear safety goggles or safety glasses with

side shields and a full face shield when needed.

We recommend Wide Vision Safety Mask for

use over eyeglasses or standard safety gl-

asses with side shields.

TEST RUN

Once mounting is complete and adjustments are

done to your satisfaction, you are ready to test

the machine.

To test run the grinder/sander:

1. Plug the machine into the power source.

2. Stand to the side of the grinding wheel and

turn the grinder ON.

The machine should run smoothly with little or

no vibration or rubbing noises. Strange or un-

usual noises should be investigated and corr-

ected before operating the machine further.

If the machine seems okay, stay out of the line

of rotation of the grinding wheel and let it run for

1 to 2 minutes to make sure the wheel is stru-

cturally sound.

All grinding wheels have the potential of b-

reaking apart during operation, causing serious

personal injury or death! Always stand to the

side of the grinder when turning it ON and

wear the proper safety equipment to protect

yourself.

WARNING

!

The grinder is a safe tool when used properly.

In addition to the safety instructions in this man-

ual, the most important safety consideration is to

use common sense at all times. What may be

okay in one situation, may not be safe in another.

Read the following statements to protect yourse-

lf before grinding:

• Make sure all guards and eye shields are in

place.

BEFORE GRINDING

• Remember that grinding often produces sparks.

DO NOT allow anyone to stand in the path of the

sparks. DO NOT grind near flammable liquids or

gases.

• Wear the proper protective clothing. Remember

that particles flying off of a grinding wheel will be

traveling very fast. Wear safety glasses or a face

shield, a dust mask, earplugs, a leather apron and

heavy leather boots.

• DO NOT lean into the workpiece in a manner that

may cause your hands to move into the spinning

wheel if the workpiece slips off.

• Concentrate on the task at hand. STOP grinding/

sanding if there are distractions.

NOTICE! The grinder is designed for use with

hard metals only. Soft metals and wood pro-

ducts should only be used on the sanding belt.

They will quickly load the grinding wheel surface

and ruin its abrasive qualities.

OPERATING GRINDER

To grind with the grinding wheel:

1. Fill the coolant tray 3/4 full with water.

2. Move the red switch to the ON position

.

3. Allow the machine to run for at least 1 full minute

to ensure that the grinding wheel is safe for use.

4. Grasp the workpiece tightly and properly support

it on the tool rest.

5. Place the workpiece against the front surface of

the wheel with moderate pressure, moving it back

and forth in a steady, even motion.

6. Regularly dip the workpiece into the coolant tray

to cool it off.

7. When you are ready to stop the grinder, move the

red switch to the OFF position. At this point, DO

NOT continue grinding and DO NOT manually

stop the grinding wheel with your workpiece!

Note: Using too much pressure will slow the motor

and may damage the wheel. Using too little pres-

sure will make the workpiece bounce around and

you will not make good contact with the wheel.

CAUTION! The sanding belt will remove large amo-

unts of material quickly, including your skin. DO NOT

touch the sanding belt and always position your

hands so they will not slip into the belt or get caught

SANDING

Summary of Contents for TLGS625

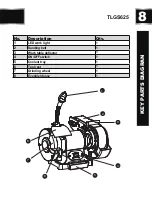

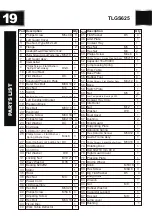

Page 18: ...18 EXPLONED VIEW TLGS625...