13

TLGS625

MAINTEN

ANCE

1. Maintain the tool with care. A tool in good con-

dition is efficient, easier to control and will have

fewer problems.

2. Inspect the tool components periodically. Repair

or replace damaged or worn components.

3. Follow instructions for lubricating and changing

accessories.

4. When servicing, use only identical replacement

parts. Only use accessories intended for use with

this tool. Replace damaged parts immediately.

5. Maintain the tool’s label and name plate. These

carry important information.

6. Wheels should be dressed periodically to mai-

ntain grinding efficiency, especially if they become

clogged from grinding soft metals. Use a grinding

wheel dresser to restore the wheel’s original

shape.

7. Keep all parts in working order. Check to dete-

rmine that the guard or other parts will operate

properly and perform their intended function.

8. A guard or other part that is damaged should be

properly repaired or replaced. Do not perform

makeshift repairs. Use the parts list provided to

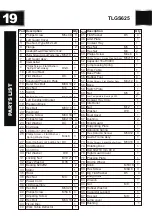

order replacement parts.

9. Disconnect tool when changing grinding wheels.

10. Replace a cracked wheel immediately and use

only flanges supplied with the grinder.

Only qualified service personnel should repair the

tool. An mproperly repaired tool may present a

hazard to the user and/or others.

WARNING

!

Your safety depends, on a large part, on the co-

ndition of the wheel during grinding. A wheel in poor

condition may break apart during rotation, injuring

the operator, a bystander and possibly causing

property damage.

To properly care for your wheel, follow these tips:

• Always transport, store and handle wheels with

care. Wheels may be damaged if they are dro-

pped or if heavy objects are stacked on them.

• Select the right grinding wheel for the job. DO

NOT grind material that is not designed for the

wheel.

• Select the right wheel for the machine. A mac-

hine that rotates at a higher RPM than the wheel

WHEEL CARE

rating may cause the wheel to fly apart.

• Mount the wheels properly (see Replacing

Wheels). Never use a wheel with the wrong

arbor size for the grinder.

• DO NOT abuse the wheel by jamming the work

into the grinding wheel with excessive force.

• Grinding on the side of the wheel may cause

wheel damage.

• Dress the grinding wheel when the surface loses

its abrasive quality or bite.

Dressing restores the grinding wheel’s abrasive

quality. Whenever the front surface of the wheel

loses its abrasive qualities (loading or polishing),

then the wheel should be dressed.

To dress the grinding wheel:

1. With the machine plugged into power, stand

to the side of the grinding wheel and move the

red switch to the ON position.

2. Allow the machine to run for 1 full minute to

make sure that the grinding wheel is not going

to fly apart and injure you, then move to the

front of the machine.

3.Hold the dressing tool firmly on the tool rest

with both hands and press it lightly against

the front surface of the grinding wheel as

shown( in Fig10).

4.Move the dressing tool in a side-to-side motion,

while keeping it even with the front surface of

the grinder.

5.Regularly pull the dressing tool away from the

wheel for visual inspection and repeat Steps 3

& 4 until the surface of the wheel appears to be

restored to its normal color and texture.

WHEEL DRESSING

Figure 10

Summary of Contents for TLGS625

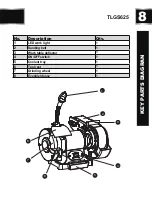

Page 18: ...18 EXPLONED VIEW TLGS625...