16

BD4603

TLGS625

TR

OUBLESHOO

TING GUIDE

Problem(s)

Possible Cause(s)

Suggested Solution(s)

Grinder won’t start.

1. Blown line fuse or tripped

circuit breaker.

2. Low line voltage.

3.

Material wedged between

wheel and guard.

4. Defective switch.

5. Defective, blown capacitor.

6. Defective circuit board.

1. Replace with fuse of proper size, if

fuse is blown. Reset tripped breaker.

2. Check power supply for voltage and

correct as needed.

3. Turn grinder off and remove material.

4. Replace switch.

5. Replace capacitor

6. Replace circuit board.

Excessive vibration.

1. Improper mounting of

grinder or accessories.

2. Grinding wheel out of balance.

1. Remount bench grinder.

2.

Dress wheels or replace wheels.

Motor overheating.

1. Excess pressure required

to grind material.

2. Grinding on side of wheel.

3. Motor not turning freely

(without power).

1. Dress or replace wheels.

2.

Grind only on face of wheel.

3. Clean around wheels and shaft

and/ or replace bearings.

Fuses are being

blown or circuit

breakers tripped.

1.

Overloading due to binding.

2. Defective plug.

3. Defective cord.

4. Defective switch.

1. Clean around wheels and shaft

and/

or replace bearings.

2. Replace plug.

3. Replace cord.

4. Replace switch.

Machine slows

when operating.

1. Depth of cut too great.

1. Slow down the rate of movement of

the workpiece into wheel.

Wavy condition on

1. Machine vibrating.

2.

Workpiece not being held

firmly.

3. Wheel face uneven.

4. Wheel is too hard.

Make sure machines is securely

mounted on a solid surface.

2.

1.

Use a holding device to firmly

retain the workpiece.

3. Dress the grinding wheel.

4. Use softer wheel, or reduce the

feed rate.

surface of workpiece

.

Lines on surface of

workpiece.

1. Impurity on wheel surface.

2. Workpiece not being held

tightly.

1. Dress the grinding wheel.

2. Use a holding device to firmly retain

the w orkpiece.

1. Improper type of grinding

wheel.

2. Improper feed rate.

3. Coolant required.

Burning spots or

cracks in the

workpiece.

1. Try a wheel which is softer style

or a coarser grit.

2. Slow down the rate of movement

of the workpiece into w heel.

3. Add optional coolant system or

introduce coolant by hand .

Summary of Contents for TLGS625

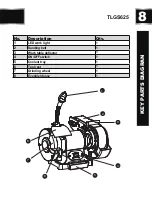

Page 18: ...18 EXPLONED VIEW TLGS625...