BD4603

SAFETY GUIDELINES

3

TLGS625

GENERAL SAFETY GUIDELINES

BEFORE USING THIS POWER

TOOL

• Operate in a safe work environment. Keep

your work area clean, well lit and free of

distractions.

• Keep anyone not wearing the appropriate s

afety equipment away from the work area.

• Store tools properly in a safe and dry location.

Keep tools out of the reach of children.

• Do not install or use in the presence of flam-

mable gases, dust or liquids.

• Always wear impact safety goggles that

provide front and side protection for the eyes.

Wear a full-face shield if your work creates

metal filings or wood chips. (Eye protection

equipment should comply with ANSI Z87.1

standards.)

• Wear gloves that provide protection based on

the work materials or to reduce the effects of

tool vibration.

• Non-skid footwear is recommended to main-

tain footing and balance in the work environment.

• Wear the appropriate rated dust mask or

respirator.

• Do not operate any tool when tired or under

the influence of drugs, alcohol or medications.

• Avoid wearing clothes or jewelry that can b-

ecome entangled with the moving parts of a

tool. Keep long hair covered or bound.

• Do not overreach when operating the tool.

Proper footing and balance enables better

control in unexpected situations.

• Securely hold the material using both hands.

Applying the material to the grinder with only

one hand can result in a loss of control.

• Never use a tool with a cracked or worn gri-

nding wheel. Change the grinding wheel

before using.

• Replace cracked wheel immediately. Use only

flanges supplied with the grinder.

• Clean dust and debris from beneath the gri-

nding wheels frequently.

• Do not start the tool if the grinding wheel is in

contact with the workpiece.

• Always ensure the safety guards are attached

correctly and do not operate the bench grinder

without the guards attached. Adjust the dista-

nce between the wheel and the tool rest to

maintain a 1/16 in. or less separation as the

diameter of the wheel decreases with use.

• Use an appropriate dust respirator when working

for an extended period of time. This will help

prevent breathing in the fine dust created while

grinding.

• Do not grind on the sides of grinding wheels

unless they are specifically designed for that

purpose.

• Before using the tool on the workpiece, run the

tool at the highest speed, without a load, for at

least 30 seconds in a safe position. Stop im-

mediately if there is any vibration or wobbling

that could indicate poor installation or a poorly

balanced grinding wheel. Check the tool to

determine the cause.

• Do not allow the motor to overload or overheat.

Take breaks to rest the tool.

• Do not subject the grinding wheel to any lateral

pressure as it may damage the tool or cause

it to kickback.

ADDITIONAL SPECIFIC SAFETY

RULES

1. Only use a grinding wheel with the correct arbor

size and shape that matches the grinder’s

spindle.

2. Ensure the grinding wheel has a clean edge.

Check the grinding wheel for wear or chipping

and replace if necessary.

3. Never install more than one grinding wheel at

a time unless the tool and wheels are design-

ed for that purpose.

4. A large amount of sparks will be created when

working with a grinding wheel. Hold the tool

so that sparks fly away from you and other

persons or flammable materials. Have a fully

charged fire extinguisher present.in the event

of a fire.

5. Do not subject the grinding wheel to any

lateral pressure as it may damage the

tool or cause it to kickback.

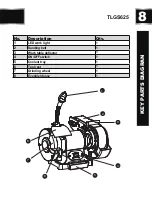

Summary of Contents for TLGS625

Page 18: ...18 EXPLONED VIEW TLGS625...