SAFETY GUIDELINES

4

TLGS625

6. Disconnect tool from power source before

cleaning, servicing, changing parts/accessor-

ies or when not in use.

7. Protect yourself against electric shocks when

working on electrical equipment. Avoid body

contact with grounded surfaces. There is an

increased chance of electrical shock if your

body is grounded.

8. Do not expose tool to rain or water entering a

power tool will increase the risk of electric shock.

9. Do not disconnect the power cord in place of

using the ON/OFF switch on the tool. This will

prevent an accidental startup when the power

cord is plugged into the power supply.

10. Do not alter any parts of the tool or accessories.

All parts and accessories are designed with

built-in safety features that may be compro-

mised if altered.

11. Make certain the power source conforms to

requirements of your equipment.

12. Do not allow the tool to run without load for an

extended period of time, as this will shorten

its life.

13. Do not cover the air vents. Proper cooling of

the motor is necessary to ensure normal life

of normal life of the tool.

14. Avoid unintentional starting. Ensure the switch

is off when connecting to the power source.

15. In the event of a power failure, turn off the

machine as soon as the power is interrupted.

interrupted. The possibility of accidental injury

could occur if the power returns and the unit is

not switched off.

16. Disconnect the power source before installing

or servicing the tool.

17. After making adjustments, make sure that any

adjustment devices are securely tightened.

18. Remove adjusting keys and wrenches before

turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool increases

the risk of personal injury.

19. Never force the tool. Excessive pressure could

break the tool, resulting in damage to your

workpiece or serious personal injury. If your tool

runs smoothly under no load, but does not run

smoothly under load, then excessive pressure

is being used.

20. Do not touch an operating motor. Motors can

operate at high temperatures.

21. Only use accessories that are specifically

designed for use with the tool. Ensure the

accessory is tightly installed.

22. Only use an accessory that exceeds the No

Load Speed rating.

23. Do not touch an operating motor. Motors can

operate at high temperatures and can cause

a burn injury.

24. Insert the power cord plug directly to the power

supply whenever possible. Use extension cords

or surge protectors only when the tool's power

cord cannot reach a power supply from the work

area.

25. Do not operate this tool if the power cord is fr-

ayed or damaged as an electric shock may

occur, resulting in personal injury or property

damage.

26. Inspect the tool's power cord for cracks, fraying

or other faults in the insulation or plug before

each use.

27. Discontinue use if a power cord feels more than

comfortably warm while operating the tool.

28. Keep all connections dry and off the ground to

reduce the risk of electric shock. Do not touch

plug with wet hands.

29. Do not allow people, mobile equipment or ve-

hicles to pass over unprotected power cords.

30. This tool vibrates during use. Repeated or long-

term exposure to vibration may cause tempo-

rary or permanent physical injury, particularly

to the hands, arms and shoulders.

Summary of Contents for TLGS625

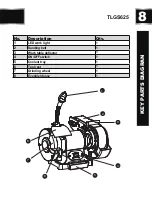

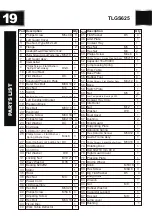

Page 18: ...18 EXPLONED VIEW TLGS625...