BD4603

9

TLGS625

ASSEMBL

Y INSTR

UCTIONS

The tool rest attaches to the inward side of

the guard and provides a surface that must

be used to support the workpiece during

operation. Certain types of grinding/sanding

may require jigs or accessories that will be

used with the tool rests to assure the proper

angle of the workpiece against the wheel.

Failure to install and use the tool rest can lead

to serious personal injury.

To install the tool rests:

1.Loosely attach the tool rests perpendicular

to the belt or wheel surface with the knob

bolts, 5 mm washers and hex nuts.

2.To adjust the angle of the sanding belt

tool rest, use a square or a protractor to

set the angle of the tool rest in relation

to the sanding belt.

3.Adjust both tool rests approximately 1/16

to 1/8 in. from the grinding wheel and the

sanding belt and tighten the knob bolts.

(

in Fig. 3

)

shows the correct adjustment

for the tool rest at the grinding wheel.

INSTALLATION TOOL RESTS

Figure 3

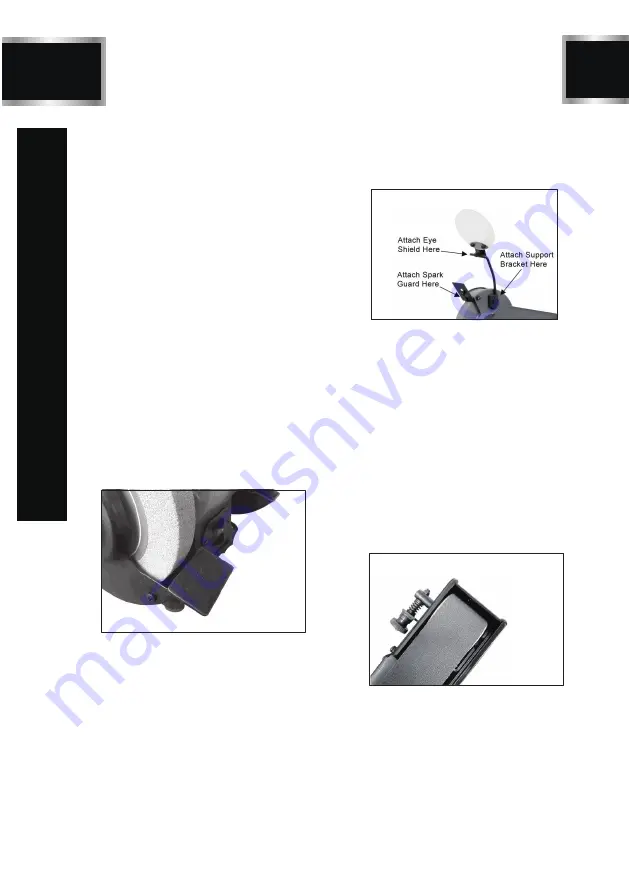

The spark guard must be installed and posi-

tioned 1/8 in. from the grinding wheel to minimize

sparks flying towards the operator. The eye

shield must be positioned between the grinding

wheel and the operator's face to protect the

operator from flying debris. This is not a rep-

lacement for safety glasses!

To install the spark guard and eye shield:

1.Using the included 5 mm screw and washer,

install the spark guard as shown

(

in Fig. 4

)

.

SPARK GUARD & EYE SHIELD

2. Attach the eye shield to the support bracket

with the included 6 mm carriage bolt and hex

nut. Use the 8 mm hex bolt and washer to attach

the support bracket to the grinder.

Figure 4

BELT TRACKING

Tracking the sanding belt means to center the

belt on its rollers, so that it runs balanced and

does not make contact with the sides of the

belt cover.

To track the sanding belt:

1. Disconnect the machine from the power

supply.

2. Rotate the grinding wheel.

3. As you rotate the grinding wheel, watch how

the sanding belt rides on the upper roller. If

the belt is tracking properly, the sanding belt

should be centered between the sides of the

belt cover as shown (in Fig. 5).

4. While spinning the wheel, turn the tracking

control knob counterclockwise to make the

belt move to the left, or turn the tracking

control knob clockwise to make the belt move

to the right (in Fig. 6).

5. After the belt is centered, spin the grinding

wheel approximately ten times to ensure

that the belt continues to track properly.

Figure 5

Summary of Contents for TLGS625

Page 18: ...18 EXPLONED VIEW TLGS625...