13

14

4. ACCURACY CHECK

This instrument requires no calibration. The regular accuracy checks ensure that the

instrument’s accuracy has not been impaired by falls or heavy impacts.

It is recommended to check the laser level accuracy each time before beginning workday

usage. The accuracy check procedure includes three steps: the horizontal line height check

(step 1)

, the horizontal line leveling check

(step 2)

, the vertical line leveling check

(step 3)

.

If, during one of the tests, the measured deviation exceeds the allowable deviation, repeat

the test procedure. Should the readings persist over the allowable deviation, the instrument

is out of calibration and must be serviced.

Contact ToughBuilt

®

Customer Service for additional support.

The following accuracy check procedure suggests the most practical scenarios

at the recommended distance.

The surface of the area where the accuracy check procedure is conducted must be

sufficiently level, so that the instrument remains within the self-leveling range of ± 4°

from the 0° level position.

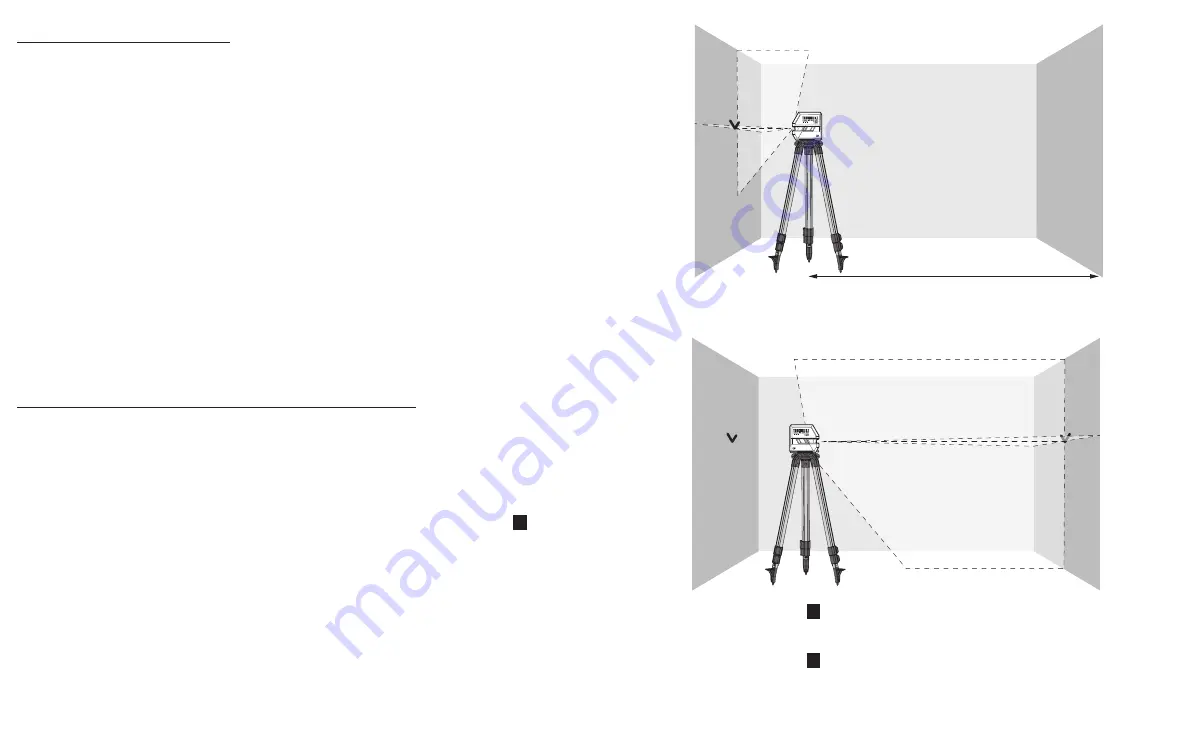

Step 1:

Checking the Height Accuracy of the Horizontal Line

For this check, a minimum measuring distance of 16' (5m) from the instrument to the

opposite wall in a dimly lit room is required.

1.

Place the instrument on a firm and level surface or mount the instrument onto a tripod

close to

wall A.

2.

Turn on the instrument in the self-leveling mode by sliding the Pendulum Switch

2

to the UNLOCK position.

3.

Direct the laser beam against wall A and allow a few seconds for the visible line to

stabilize. Mark the center of the horizontal line projected by the instrument on

wall A (point a1).

4.

Rotate the instrument by 180°, allow it to self-level, and mark the center of the horizontal

line on the opposite

wall B (point b)

.

5.

Slide the Pendulum Switch

2

to the LOCK position.

6.

Without turning the instrument, place it close to

wall B.

7.

Slide the Pendulum Switch

2

to the UNLOCK position and allow the visible line

to stabilize.

B

A

a1

16' (5m)

B

A

a1

b

Summary of Contents for TB-H2-LL-100-L2

Page 14: ...23 24...