- 32 -

tousek

/ EN_TPS-60-PRO_05 / 25. 03. 2020

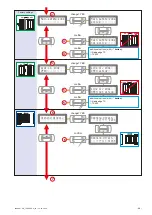

5

1

4

2o

6o

3a

2s

3a

3b

6s

7

3b

9

8

2x0,75 mm

2

4x0,75 mm

2

coaxial cable

2x1,5 mm

2

2x0,75 mm

2

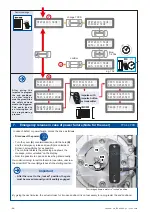

The

0,75mm

2

control

lines

are

shown

witho

ut

ground

lead.

In

order to

facilitate connections

we

recommend

using

flexible

wires

and

not

using thicker wires for the control lines.

NOTE concerning cable laying

The electric

cables

have to be laid

in insulating

sleeves which are suitable for

underground us

-

age.

The insulating

sleeves have to

be lead into

the inner of the operator housing.

230 V

cables and control lines have to

be laid in

separate sleeves.

Only double-insulated

cables, which are suitable

for underground

usage

(e.g. E-YY

-J) may be used.

In case that special regulations

require

another

type of cable,

cables

according

to these regula

-

tions have to be used.

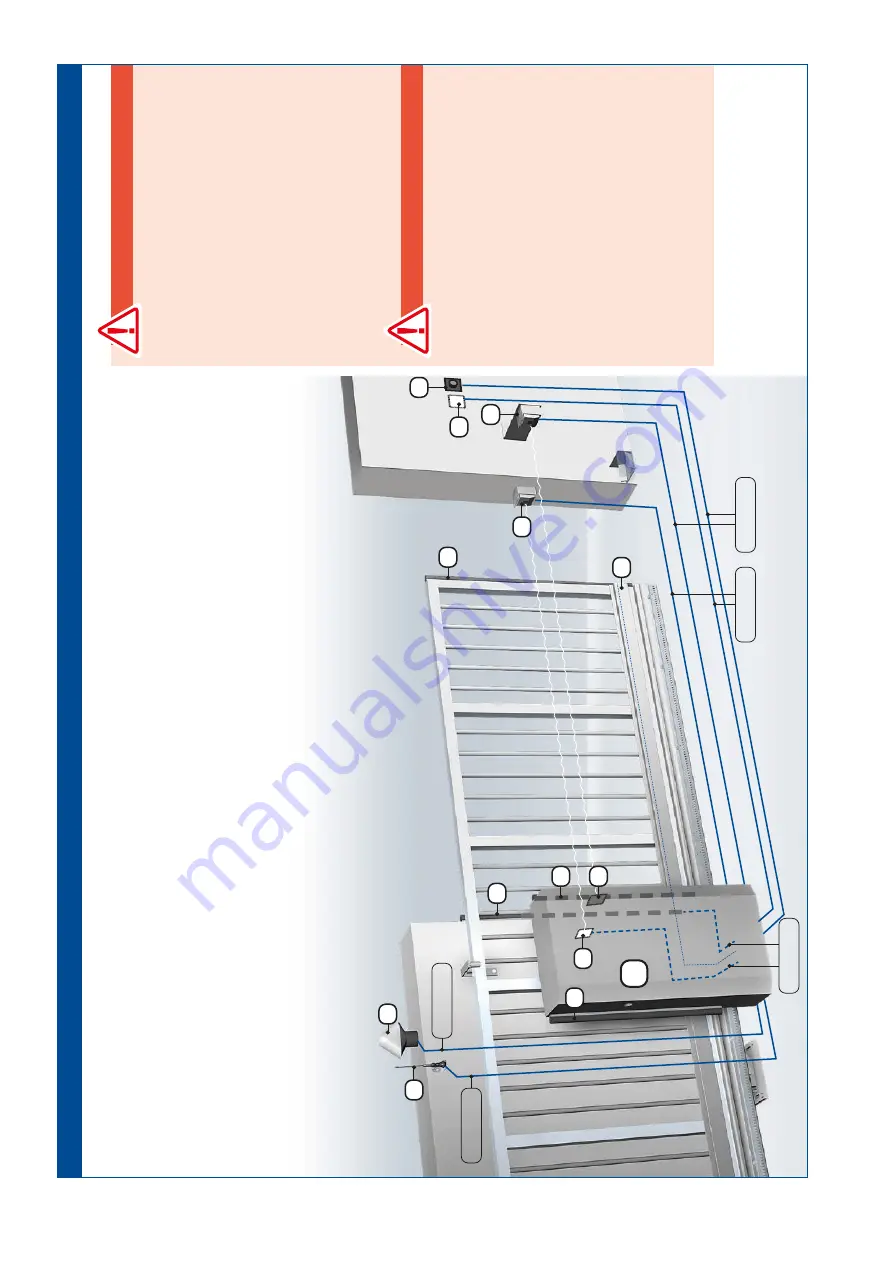

W

arning note

Pl

ease

be

aw

are

th

at

th

e b

esi

de

pi

ct

ure

is

on

ly

a symb

ol

ic

sample illustration

of a gate facility and may therefore

not

show

all

safety

devices

required

for

your

specific

application. To achieve an optimum safety

level at your gate facility

,

please make sure that all

safety components

and

acces

-

sories which - according to the applying safety rules and laws - are req

ui

red

in yo

ur parti

cu

lar case (e.

g. p

hotocel

ls,

induction

loops,

sensing

edges,

signal

lamps,

traffic

lights,

mains-

and

emergency

power

off

switches

etc.)

are properly installed, operated, and serviced. In

this

context please follow

the

EU Machine

Directive,

accident prevention

rules and

laws,

as well

as applying

EU- and national

standards in

force at the time of

instal

-

lation and operation of the gate facility

.

The

Tousek Ges.m.b.H.

cannot

be held

responsible

for

any consequences resulting

from disregard of applying

standards and laws during

installation or operation of

the gate facility

.

9.

Cable plan

Sliding gate operator TPS 60 PRO

1

Motor T

OUSEK TPS

60

PRO

incl.:

-

Control box with drive control,

Radio receiver *), loop detector *)

-

Main switch, photocell receiver

,

height-adjustable fork for current

supply *), 2 safety edges*)

(

2s - safety when closing / 2o - when opening)

*) = optional components

3

a

- outer photocell /

b

- inner photocell

4

Antenna for optional receiver

5

Signal lamp

6

s

- safety sensing edge (safe

ty during closing)

o

- safety sensing edge (safe

ty during opening)

7

Power supply sytem

TX100

When using other power sup

ply system

(e.g. TX200i)

see related inst

ruction manual

8

Key switch

9

Stop button