17

❏

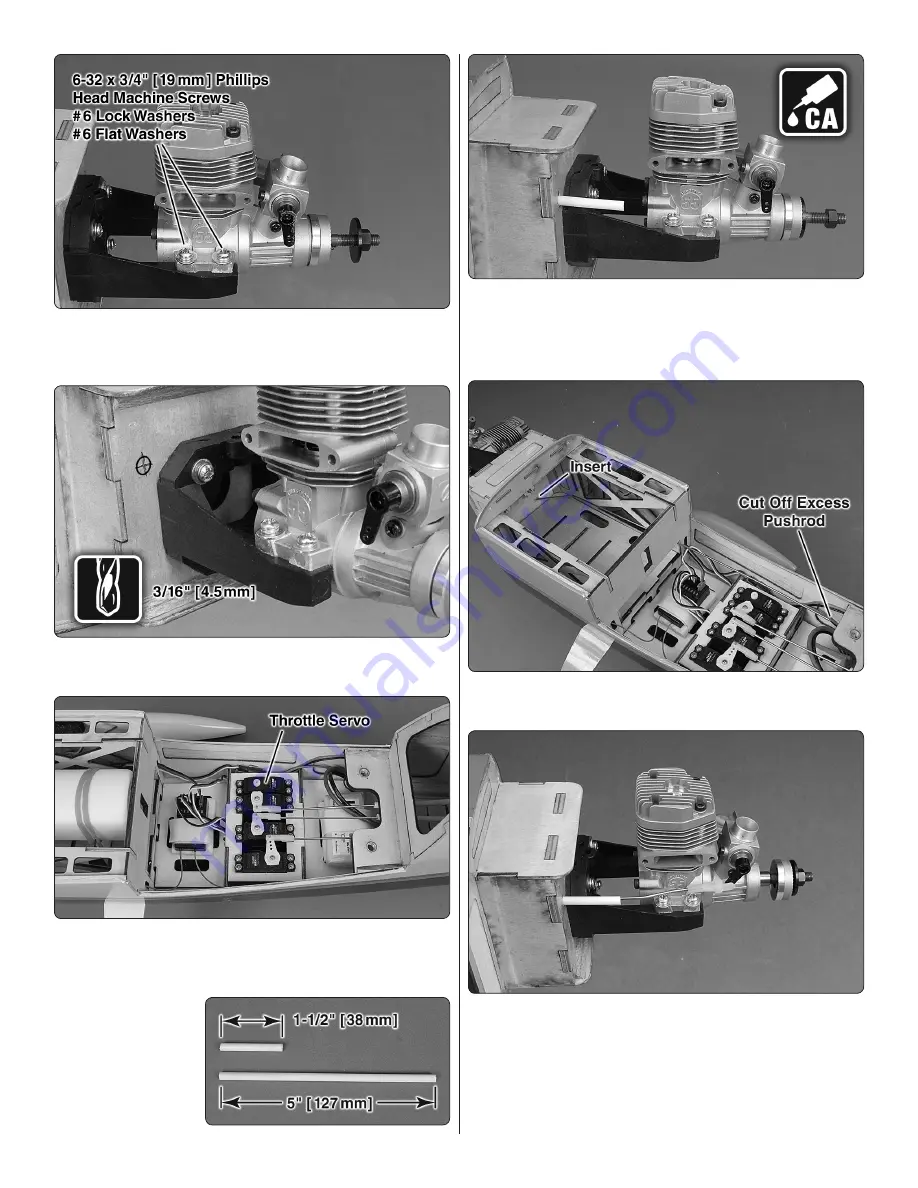

6. Position the engine so the thrust washer is 5-1/8"(130mm)

from the fi rewall. Mark and drill the four holes.Mount the

engine using the included hardware.

❏

7. Mark and drill a 3/16" (4.5mm) hole through the fi rewall

in line with the throttle arm.

❏

8. Install the throttle servo in the servo tray and plug it

into the receiver. Use thin CA to harden the threads in the

plywood servo tray.

❏

9. Cut the outer

throt tle pushrod

tubes and roughen

them with sandpaper.

❏

10. Glue the short outer pushrod tube, fl ush with the back

of the fi rewall, in the throttle pushrod hole.

❏

11. Bend the M2 x 500 mm throttle pushrod as shown

on page 27.

❏

12. Insert the throttle pushrod through the small outer

pushrod tube.

❏

13. Slide a silicone clevis retainer on a nylon clevis. Then,

thread the nylon clevis onto the throttle pushrod. Make any

needed bends to align with the throttle arm and attach the

clevis in the outer hole.