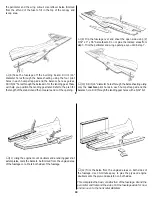

REPAIRING SURFACE DINGS

Many surface blemishes on a framed model are caused by

bumps and balsa chips on the work surface. This type of ding is

best repaired by applying a drop or two of window cleaner or

tap water to the blemish, then running a hot sealing iron over

the spot to expand the wood fibers. After the surface has dried,

sand the

expanded area smooth.

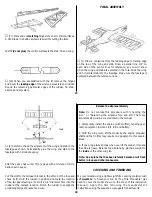

FINAL SANDING

Fill any large scuffs or dings. Then sand the entire structure with

progressively finer grades of sandpaper, ending with 320-grit.

COVER THE STRUCTURE WITH TOWERKOTE

The Fun 51 does not require any painting to obtain the scheme

shown on the box, as all of the finish is MonoKote.

Make sure the structure is smoothly sanded with 320-grit

sandpaper. Remove all dust from the structure with a vacuum

cleaner and Top Flite

®

Tack Cloth so the covering will stick well.

Cover the aircraft using the sequence that follows. Make sure the

covering is thoroughly stuck to the structure and all edges are

sealed. Use a Top Flite Hot Sock

™

on your covering iron to avoid

scratching the finish.

When covering areas that involve sharp junctions, like the tail

section or around the root end of the wing, cut narrow strips

(1/4" to 3/8") and apply them in the corners before covering the

major surfaces. The larger pieces of covering will overlap and

capture these smaller pieces. This technique also bypasses the

need to cut the covering in these areas after it has been applied.

DO NOT, under any circumstances, attempt to cut the covering

material after it has been applied to the fin and stab, except

around the leading and trailing edges.

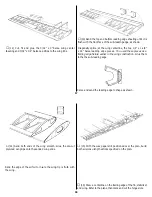

RECOMMENDED COVERING SEQUENCE

❍

1. Tail junction strips as described above

❍

2. Wing/fuse junction

❍

3. TE surfaces of wing

❍

4. Bottom of left and right wing panels

❍

5. Top of left and right wing panel and wing tips

❍

6. Fuse sides (overlap at top and bottom)

❍

7. Stab bottom

❍

8. Stab top

❍

9. Fin left and right side

❍

10. Rudder left and right side

❍

11. Bottom of elevators

❍

12. Top of elevators

❍

13. Ends of ailerons

❍

14. Bottom of ailerons

❍

15. Top of ailerons

❍

16. Hatch cover

21

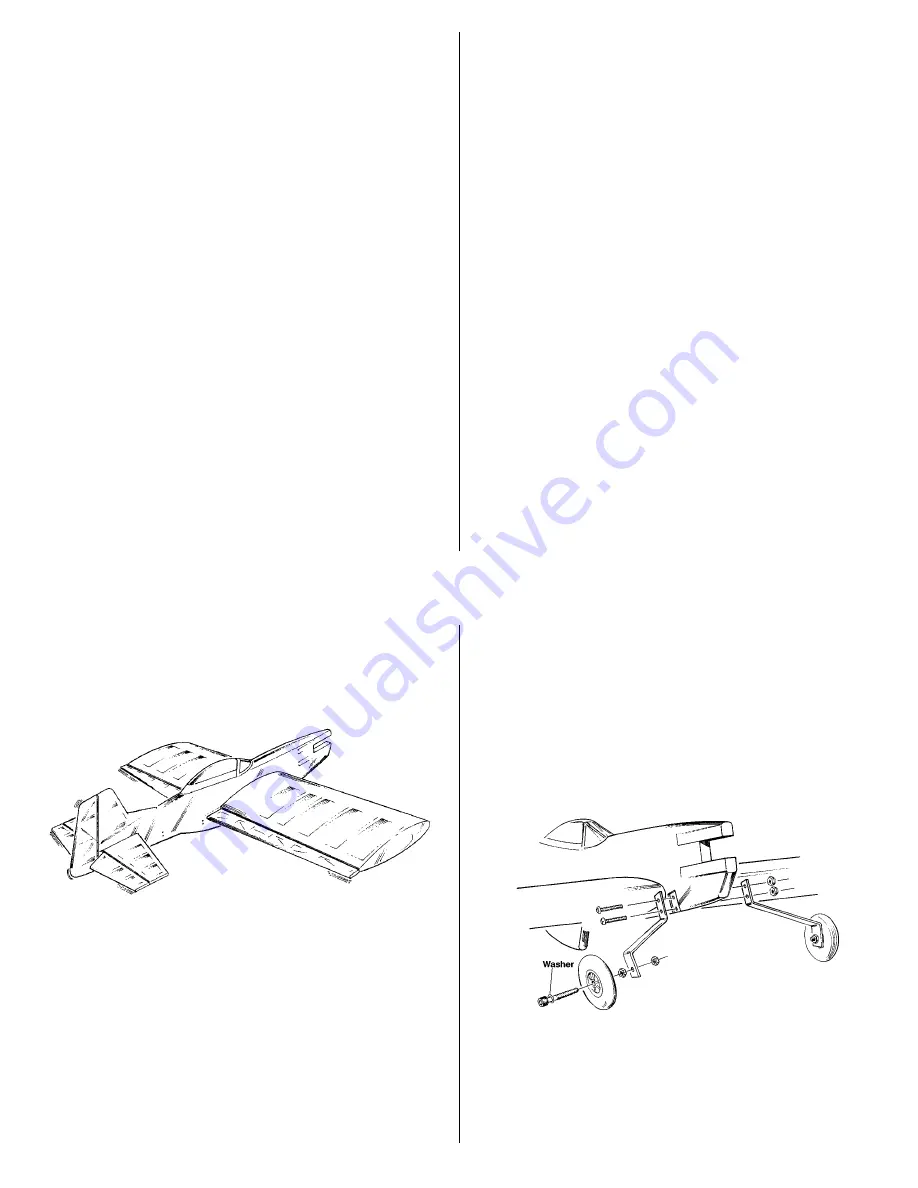

FINAL HOOKUPS AND CHECKS

❍

(1) Lay the control surfaces over the plans for reference and

mark the location of the hinge slots.

Cut through the covering at each hinge slot on the control

surface and its mating part.

Roughen the elevator joiner wire with coarse sandpaper. Pack

30-minute epoxy into the holes in the elevator halves with a

toothpick. Insert the joiner wire into both elevators and place

the assembly on a flat surface to cure. Be sure the elevator

leading edge is straight before the epoxy cures.

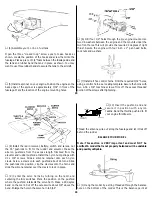

❍

(2) Install the elevator and ailerons using hinges. When

satisfied with the fit, place a few drops of CA glue into both

sides of each hinge. After the CA has cured, move each control

surface to loosen them up.

Put a dab of petroleum jelly on the top and bottom of the tail

gear bracket where the wire passed through it. Pack the hole in

the rudder with 30-minute epoxy, Then, fit the rudder in position

with hinges. Apply thin CA to both sides of each hinge.

❍

(3) Poke two holes through the covering at the bolt locations

for the landing gear struts. Bolt the struts to the fuselage, using

two 6-32 x 3/4" pan head screws and two 6-32 lock nuts.

Install the wheels on the landing gear struts using two 8-32

x 1-1/4" bolts, two #8 flat washers and four hex nuts.

22