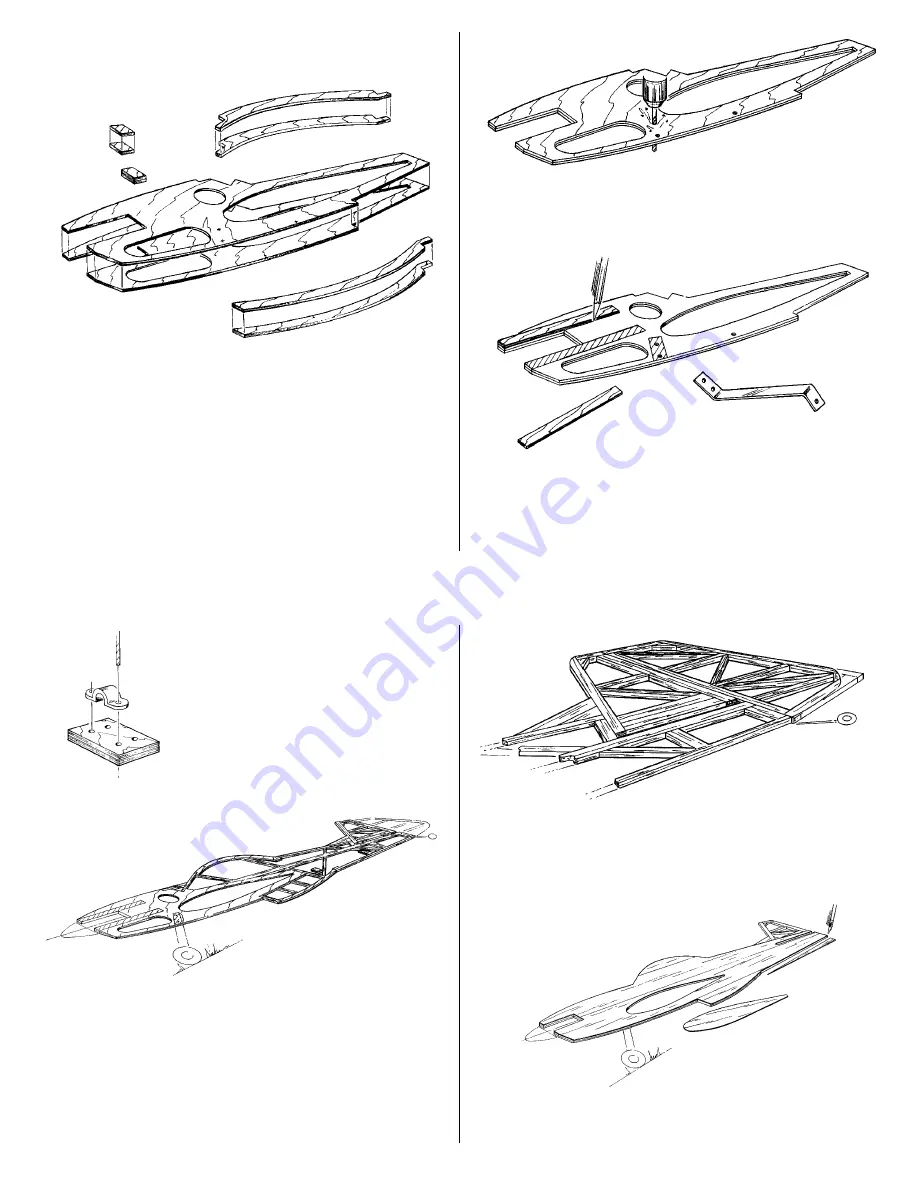

BUILD THE FUSELAGE, FIN AND RUDDER

❍

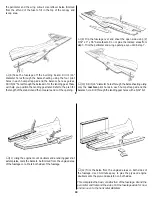

(1) Punch out the plywood die-cut parts. Use 30-minute

epoxy to laminate the fuselage core, scoop frame, canopy frame

& hump strap pads together.

Note: The airfoil shape that you punched out of the fuselage

core will be used for the wing tips in step 14, of “Build The

Wing And Ailerons.” The front of the engine cut-out, as well as

the ellipse from the wing tips, is not needed during construction.

You may save these for later use as scrap.

❍

(2) Drill a 5/32" diameter hole through the laminated fuselage

core at the two landing gear center marks and also at the

balance point.

❍

(3) Using the 1/8" x 1/2" x 6" plywood engine doublers and

the aluminum landing gear struts, mark the area on the fuselage

core as shown. When installing the side sheeting, do NOT apply

glue to the areas you just marked. Be sure to mark both sides of

the assembly.

7

❍

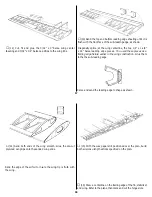

(4) Using a hump strap as a

template, drill four 1/16" diameter

holes through the two hump strap

pads. Set these pads aside for now.

Note: Use only one of the six 1/4" x 3/8" x 36" balsa sticks to

build the fin and rudder.

❍

(5) Pin the entire fuselage portion of the plan over your

building board and cover the plan with wax paper. Build the

fuselage and fin over the plan as shown. Glue the hump strap

pads to scrap balsa shims as shown. Without glue, use 1/4"

leftover balsa spacers to maintain stab slot width.

❍

(6) Build the rudder over the plan as shown.

❍

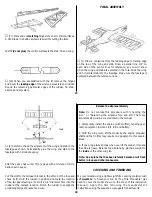

(7) Glue two 3/32" x 3" x 36" balsa sheets to one side of the

fuselage frame. Make sure that you do NOT glue the sheeting to

the areas that you marked in step 3. Trim the sheeting around

8