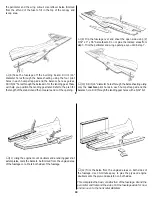

the perimeter and the wing cutout. Use leftover balsa trimmed

from the aft end of the fuse to fill in the top of the canopy and

scoop area.

❍

(8) Take the fuselage off the building board. Drill 1/16"

diameter holes through the balsa sheeting using the four pilot

holes in each hump strap pad and the balance hole as guides.

Drill 5/32" holes through the balsa skin for the landing gear. These

will help you position the landing gear later. Refer to the plan for

the length of the stab slot and then measure and cut the opening.

❍

(9) Flip the fuselage over and sheet the open side using (2)

3/32" x 3" x 36" balsa sheets. Do not glue the marked areas from

step 3. Trim the perimeter and wing opening as you did in step 7.

❍

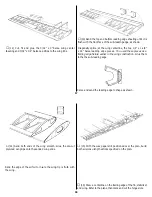

(10) Drill 1/16" diameter holes through the balsa sheeting using

only the rear two pilot holes in each hump strap pad and the

balance hole. Drill through the landing gear holes with a 5/32" bit.

9

❍

(11) Using the engine mount doublers and a landing gear strut

as templates, mark the balsa to be trimmed from the unglued area

of the fuselage core. Mark both sides of the fuselage.

❍

(12) Trim the balsa from the unglued areas on both sides of

the fuselage. Use 30-minute epoxy to glue the plywood engine

doublers onto the plywood skeleton on both sides.

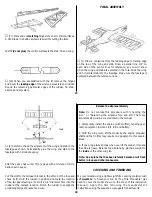

This completes the basic construction of the fuselage. Round the

perimeter and flat sand the sides. Put the fuselage aside for now

and move on to the horizontal stabilizer.

10