READ THROUGH THIS MANUAL

BEFORE STARTING CONSTRUCTION.

IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE

ASSEMBLY AND USE OF THIS MODEL.

WEIGHT

7– 8.25 lb [3170–3740 g]

WING LOADING

22– 25 oz/ft

2

[67–76 g/dm

2

]

RADIO

4–6 channel

To w e r

Hobbies

®

guarantees

this kit to be

free from defects

in both material and

workmanship at the

date of purchase. This

warranty does not cover any

component parts damaged by

use or modification. In no case

shall Tower Hobbies’ liability exceed

the original cost of the purchased kit.

Further, Tower Hobbies reserves the right to

change or modify this warranty without notice.

In that Tower Hobbies has no control over the final

assembly or material used for final assembly, no

liability shall be assumed nor accepted for any damage

resulting from the use by the user of the final user-assem-

bled product. By the act of using the user-assembled product,

the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the

use of this product, the buyer is advised to return this kit immediately in

new and unused condition to the place of purchase.

To make a warranty claim send the defective part or item to Hobby Services at

the address below:

Hobby Services • 3002 N. Apollo Dr. Suite 1 • Champaign IL 61822 • USA

Include a letter stating your name, return shipping address, as much contact information

as possible (daytime telephone number, fax number, e-mail address), a detailed description

of the problem and a photocopy of the purchase receipt. Upon receipt of the package the

problem will be evaluated as quickly as possible.

WA

R

R

A

N

TY

TOWA2058

©

2015 Tower Hobbies.

®

A subsidiary of Hobbico, Inc.

®

®

TOWER HOBBIES

Champaign, Illinois

(217) 398-8970 ext. 5

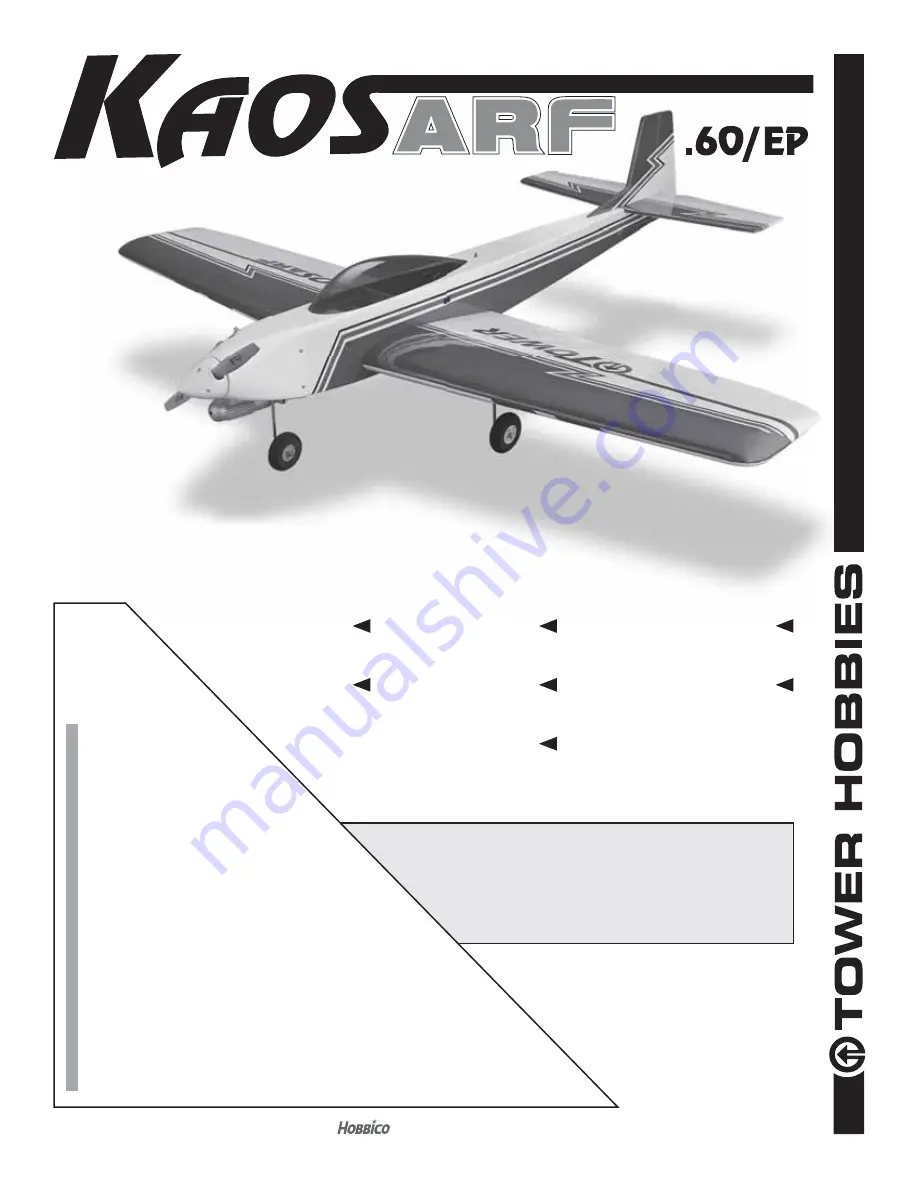

WINGSPAN

62 in [1575 mm]

WING AREA

748 in

2

[48.2 dm

2

]

LENGTH

57.5 in [1460mm]

airsupport@hobbico.com

I N S T R U C T I O N M A N U A L

POWER

Engine: .61 2-stroke –

.91 4-stroke glow,

RimFire .80 50-55-500 kV

Brushless Electric