10

Use a ruler at the widest part (front to back) of the trailing edge

of each control surface to measure the throws, then adjust

as necessary to get the measurements in the following chart.

If your radio does not have dual rates, we recommend setting

the throws at the low rate, or between the high and low rates.

NOTE

: The throws are measured at the

widest part

of the

elevators, rudder and ailerons.

These are the recommended control surface throws:

ELEV

A

TOR

R

UDDER

AILER

ONS

LOW RATE

5/16"

[8mm] 9°

Up

1/4"

[6mm] 9°

Up

5/8"

[16mm] 13°

Right

HIGH RATE

7/16"

[11mm] 12°

Up

3/8"

[10mm] 14°

Up

1"

[25mm] 21°

Right

5/16"

[8mm] 9°

Down

1/4"

[6mm] 9°

Down

5/8"

[16mm] 13°

Left

7/16"

[11mm] 12°

Down

3/8"

[10mm] 14°

Down

1"

[25mm] 21°

Left

If you don’t get the throws specified you can use the

programming in your transmitter to adjust the servo travel, and/

or adjust the throws mechanically by changing the mounting

location of the pushrods in the servo arm and control surfaces

as shown:

Pushrod Farther Out

LESS

THROW

Pushrod Closer In

MORE

THROW

Pushrod Farther Out

MORE

THROW

Pushrod Closer In

LESS

THROW

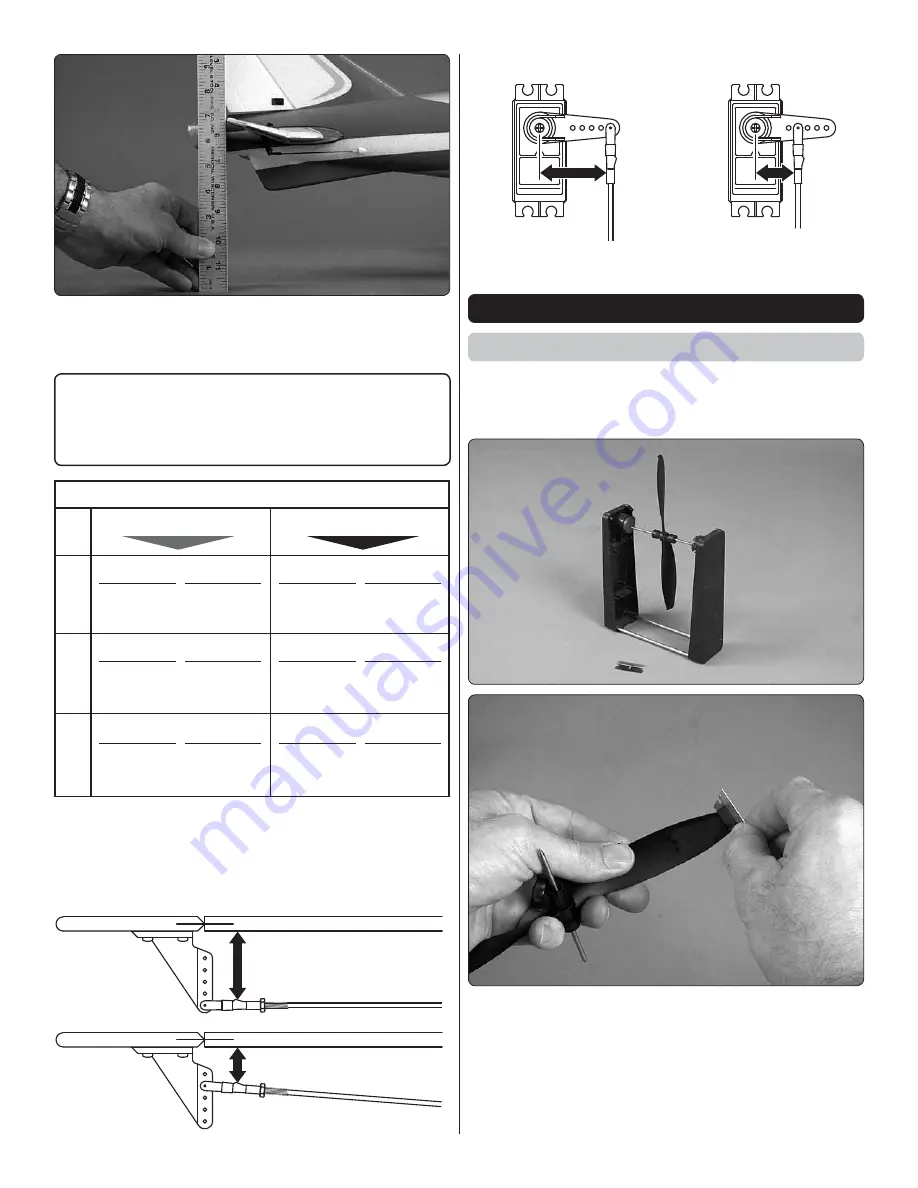

PREFLIGHT

Balance the Propeller

An unbalanced prop can cause enough vibration to damage

parts or break glue joints. At the least, an unbalanced prop

reduces motor performance.

❏

1. Use a Top Flite

®

Precision Magnetic Prop Balancer

(TOPQ5700) to balance your propeller and spare propellers.

Use a single-edge razor blade or sandpaper to remove material

from the heavy blade until the prop balances.

❏

2. Once you have all the control throws set and are done

working on the model with your radio system turned on,

remount the propeller and spinner to the motor.