E. Use medium CA to glue the wire to the rod.

F. Cut the heat shrink into 1-1/2" lengths (four total pieces). Slide

the shrink tubing onto the rods over the wire. Leave about a

1/8" overhang off the end of the dowel. Use a heat gun or

cigarette lighter to tighten the shrink over the wire and dowel.

G. Apply thin CA inside each end of the heat shrink tubing to

complete the pushrod assembly.

❍

5. The Rudder and Elevator control rods need to be installed

into the fuselage from the radio compartment threaded end first.

Patience is the key to getting the rods in and having them exit in

their proper locations.

❍

6. Screw the nylon clevises well onto the ends of the pushrods

(about 14 turns). Snap the clevises onto the control horns for

now, as they will be removed later to allow bending of the wire

at the servo.

❍

7. Cut a notch in the bottom wing skin to provide an aileron

lead exit. Use medium CA to glue the aileron servo tray (with

servo) in its place as shown on the plans.

❍

8. Hook up the nylon clevis to the nylon swivel. Thread a 12"

threaded end rod into each clevis. Screw these assemblies onto

the aileron torque rods down to the height shown on the cross

section at the centerline.

❍

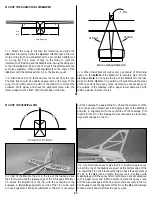

9. Mark the locations for the Z-Bends in the aileron pushrods

by holding the ailerons neutral with tape and putting marks on

the pushrods even with the holes in the servo arm. Note: When

attaching the Z-Bends to the servo arms, you’ll need to use a

5/64" drill to enlarge the holes in the servo arms. Make the

Z-Bends as shown in the following sequence

❍

10. Hook up and make final adjustments to the aileron linkage.

❍

11. Mount the wire main landing gear. Install your wheels and

tires using 5/32" wheel collars (not included) as shown on the plans.

❍

12. Locate the die-cut 1/8" plywood hatch retainer (HR).

Center the hatch retainer on the 1/8" x 4" x 5" balsa tank

compartment hatch with approximately 3/8" protruding from the

edge, then glue it in position.

47

❍

13. Position the hatch on the fuselage. Mark a cut line on the

hatch to indicate the front of the firewall. Trim the front of the hatch

to fit flush with F1A. Mark the sides of the hatch and trim it even

with the fuselage sides. Drill 1/16" holes as shown in the photo

through the hatch and into the firewall. Remove the hatch, then

enlarge the holes in the hatch only with a 3/32" drill bit.

Temporarily mount the hatch to the fuselage with #2 x 3/8" screws.

❍

14. Install the nose gear steering pushrod using the plans as a

reference. The exact installation will be dependent on your

particular selection of the pushrod.

❍

15. Install the throttle pushrod using the plans as a reference.

❍

16. Install the switch harness in the location you desire. It is

always best the switch be on the opposite side of the muffler to

prevent fuel from damaging the switch.

BALANCE YOUR MODEL

NOTE: This section is VERY important and must NOT be

omitted! A model that is not properly balanced will be unstable

and possibly unflyable.

❍

1. Use a felt tip pen or a narrow strip of tape to accurately

mark the balance point on the bottom of the wing near both sides

of the fuselage. The balance point (CG) is shown on the plan. On

the Tower Trainer 40 the (CG) is located 3-5/8" back from the

leading edge. This is the point at which your model should

balance for your first flights. Later, you may experiment by

shifting the balance up to 1/4" forward or back to change the

flying characteristics. Moving the balance forward may improve

the smoothness and arrow-like tracking, but it may require more

speed for takeoff and make it more difficult to slow down for

3-5/8"

48