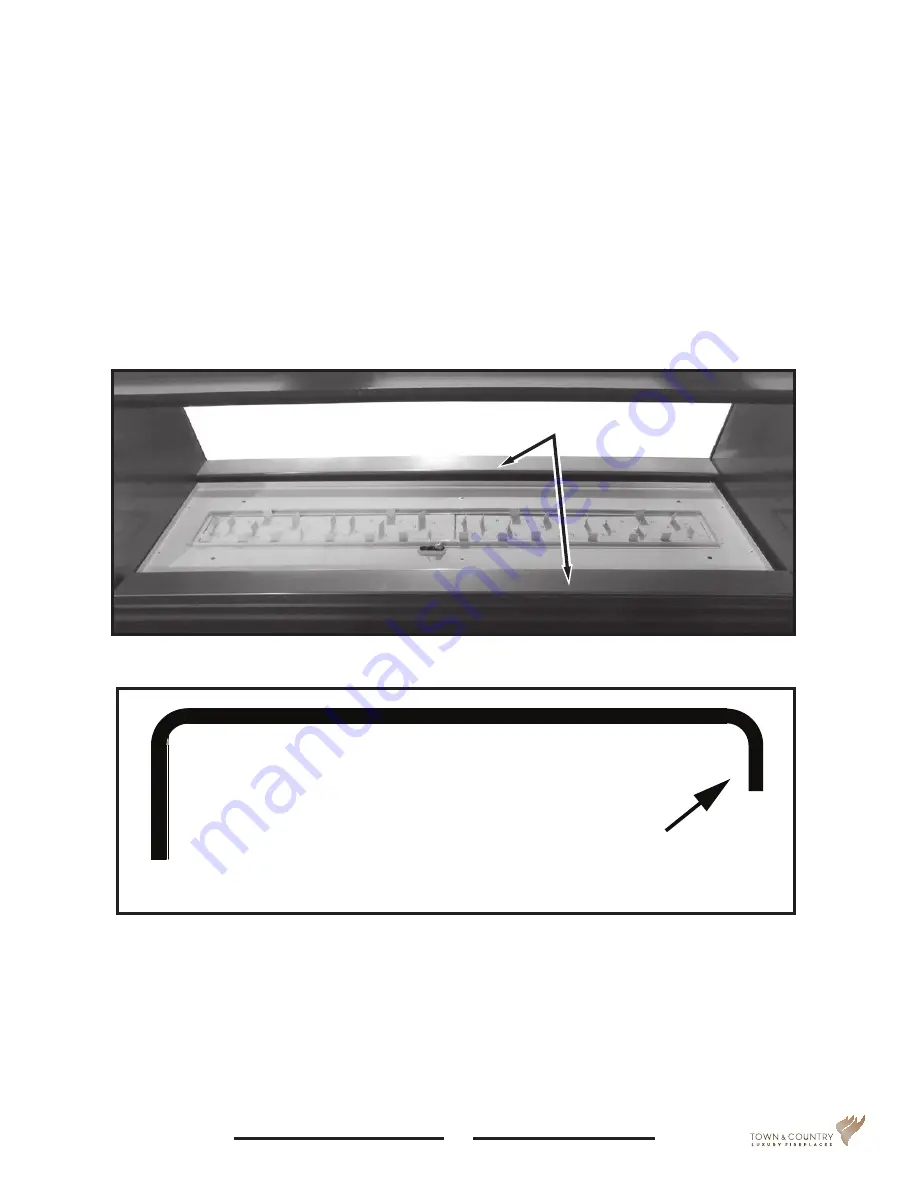

Narrow edge toward center

of fireplace

Figure 35: Edge panel profile.

TCWS.54NGST04D_120517-20

17. Pilot rock. Once all rocks have been positioned, a hollow pilot rock (Figure 32) will cover the pilot

assembly. Place it so that its side opening allows the pilot flame to extend to the burners (Figure

33).

18. Place the two edge panels along the length of the fireplace (Figure 34) with the short side facing

toward the center (Figure 35).

Enamel edge panels

Figure 34: Edge panels in place.

11

5056.425183D