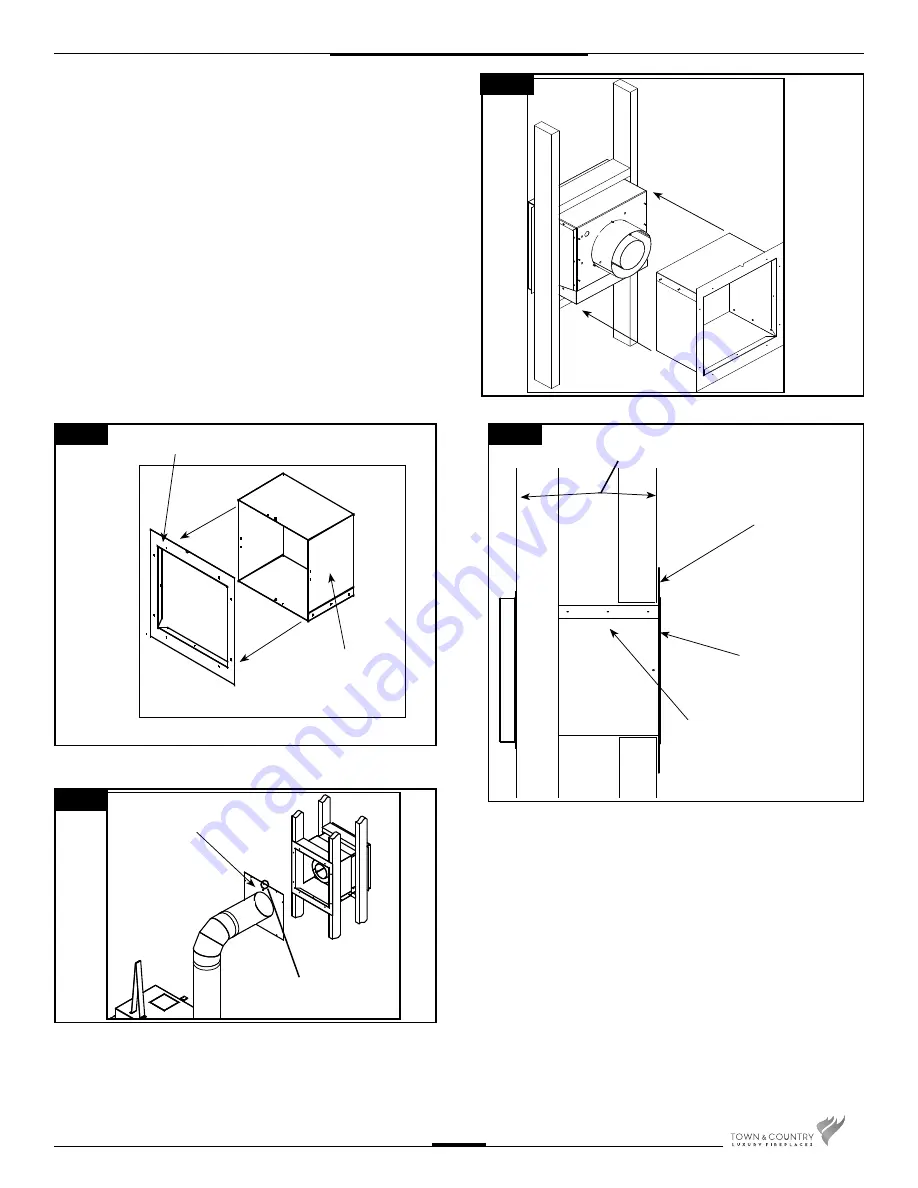

Fig. #32

Fig. #33

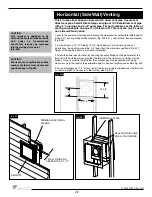

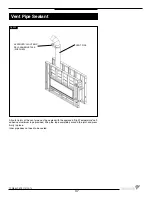

Fig. #35

INNER WALL PLATE

WALL SLEEVE

ASSEMBLY

WALL PIPE COVER

NOTCH AT TOP

Fig. #34

WALL THICKNESS GREATER THAN 7

1/2” UP TO MAX. 16 1/2”

INNER WALL PLATE

WALL SLEEVE

ASSEMBLY

WALL PIPE COVER

7. For wall thicknesses greater than 7 1/2” and up to a maximum of

16 1/2”, attach the inner wall plate to the wall sleeve assembly, using

the four screws provided.(Fig #32) Then slide this assembly over the

terminal(Fig #33 & Fig. #34).

8. Slide the wall pipe cover, with the small notch oriented at the top,

over the vent pipe and attach pipe to the fi replace. (Fig #35) Connect

the vent pipe to the vent terminal and then secure the inner wall plate

and wall pipe cover to the framing. This ensures that any insulation is

retained in the wall and that the correct clearances are maintained.

NOTE: The vent terminal comes pre-painted, but can be painted to

match your wall fi nish colour using high temperature paint that can

withstand temperatures of at least 250 degrees Fahrenheit or 120

degrees Celcius.

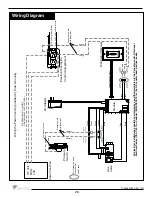

9. Run the required Simpson Duravent GS / Secure Vent /

Selkirk Direct-temp or ICC Excel Direct pipe from the unit to the

terminal assembly. Assemble as per the vent pipe manufacturer’s

instructions including all shields and fi restops.

23

TCWS.54CSTE 110712-72

Summary of Contents for TCWS54ST SERIES D

Page 70: ...70 TCWS 54CSTE 110712 72 ...