VENT PIPE

This kit uses either Simpson

Duravent GS direct vent pipe,

Secure Vent direct vent pipe,

Selkirk Direct-temp vent pipe or

ICC Excel Direct vent pipe with a

5” inner pipe and an 8” outer pipe.

For part numbers see the table of

venting components on page 19 of

this manual.

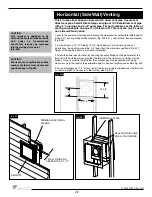

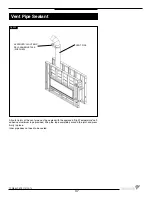

Vertical (Through Roof) Venting

Vertical installations must use the optional TCVT.PVVCA vertical adaptor box in

conjunction with this kit.

The vertical adaptor box can only be installed on a fl at surface.

Sloped surfaces require the construction of a chase which provides the minimum interior,

square opening of 11” x 11” for the venting and wiring to pass through. Flat roofs may

require a chase depending on local codes and roof construction. (If in doubt check with

local inspector)

The terminal must be located in accordance with the clearances outlined in Fig. #51 and

28.

Installation:

All part numbers in the following section

are shown in Fig. #53.

1. Place the fl ashing (Part A) onto the

chase and seal using silicone.

2. Put a bead of silicone on the underside

of the vertical standoff (Part B) and place it

on top of the fl ashing. Align the eight holes

and secure both parts to the chase using

eight #8 x 1 1/2” screws provided.

3. Install the drip shield (Part C) onto the

top of the vertical standoff using a bead of

silicone between the two. Do not screw this

part in place.

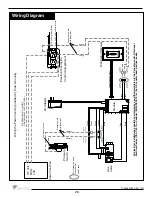

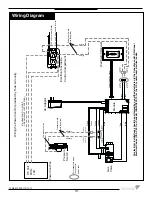

4. Bring the 14-2 electrical wire (not

supplied) up through the holes in both the

fl ashing and the drip shield leaving at least

12” of excess wire above the drip shield.

5. IMPORTANT: Attach an appropriate

length(s) of the vent to the power vent

terminal, sufficient to pass through the

chase.

NOTE: DO NOT CONNECT AN

ADJUSTABLE LENGTH VENT PIPE TO

THE TERMINAL.

6. Seal the connection of the fi rst length of

pipe at the terminal and any other pipe to

pipe joint by both screwing and taping the

outside joint using high temperature foil

tape.

7. Remove the junction box cover. (Part D)

8. Remove and discard the exhaust shield.

(Part E)

9. Apply a bead of silicone on the bottom

fl ange of the power vent terminal.

10. Slide the vent through the drip shield

and at the same time thread the electrical

lead through the hole in the bottom of the

terminal.

11. With the power vent terminal resting

on the drip shield, align the eight holes in

each of the vertical standoff, the drip shield

and the power vent terminal and then

screw them together using the eight #8 x

1/2” stainless screws provided.

12. Join the 14-2 wire lead to the blower

wires using the appropriate connectors

and attach the ground wire. Reinstall the

junction box cover.

13. Install the vertical rain cap (Part F)

over the power vent blower. ALIGN THE

EXHAUST OUTLET ON THE POWER

VENT TERMINAL WITH THE EXHAUST

PORT ON THE VERTICAL RAIN CAP.

14. Secure the vertical rain cap to the

power vent blower with the remaining eight

#8 x 1/2” stainless screws.

NOTE:

THERE ARE NO PILOT HOLES IN THE

BASE OF THE POWER VENT TERMINAL.

1/8” DIAMETER PILOT HOLES SHOULD

BE DRILLED USING THE HOLES IN THE

VERTICAL RAIN CAP AS A GUIDE.

DO NOT SILICONE THE VERTICAL RAIN

CAP TO THE POWER VENT TERMINAL

AS IT NEEDS TO BE REMOVABLE FOR

SERVICING.

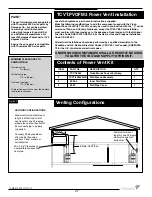

15. Run the required Simpson Duravent

GS / Secure Vent / Selkirk Direct-temp/

ICC pipe from the adaptor to the terminal

assembly. Assemble as per the vent pipe

manufacturer’s instructions including all

shields and fi restops.

34

TCWS.54CSTE 110712-72

Summary of Contents for TCWS54ST SERIES D

Page 70: ...70 TCWS 54CSTE 110712 72 ...