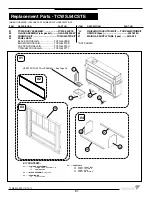

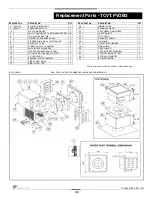

(WHEN ORDERING, INCLUDE PART NUMBER WITH DESCRIPTION)

ITEM DESCRIPTION

PART

NO.

#1 TCWS

BODY

ASSEMBLY

......................TCWS.54CSTE

#2

GLASS ASSEMBLY (c/w gasket) ..........GLAS.2062ASSY

#3 FRAMING

KIT.......................................TCWS.54STFRKIT

#4 PANEL

SETS

BLACK PORCELAIN .........................TCPN.54STBK

BROWN

PORCELAIN

.......................TCPN.54STCB

COPPER

PORCELAIN

.....................TCPN.54STCU

TITANIUM

PORCELAIN

....................TCPN.54STTI

ITEM

DESCRIPTION PART NO.

*#5

FINISHING TOUCH TRIM KIT......TCRP.54WSTRIMKIT

#6 ORIFICE

(2pcs)

.......................................5021.332A

#7

MAIN GAS SUPPLY TUBE (1pcs) ........5019.223

*

NOT SHOWN

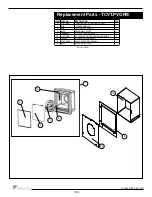

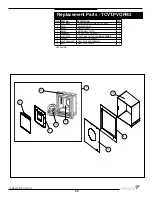

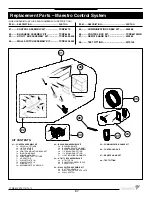

KIT CONTENTS:

#1...........TCWS BODY ASSEMBLY

1a

SPRING LATCH ASSEMBLY (2)

1b

CONTROL

BOX

#2..........GLASS ASSEMBLY

(c/w gasket)

#3..........FRAMING KIT

3a

STEEL

STUDS

#4..........PANEL SETS

4a

PANEL, FRONT BASE

4b

PANEL, LEFT SIDE

4c

PANEL,

REAR

4d

PANEL, RIGHT SIDE

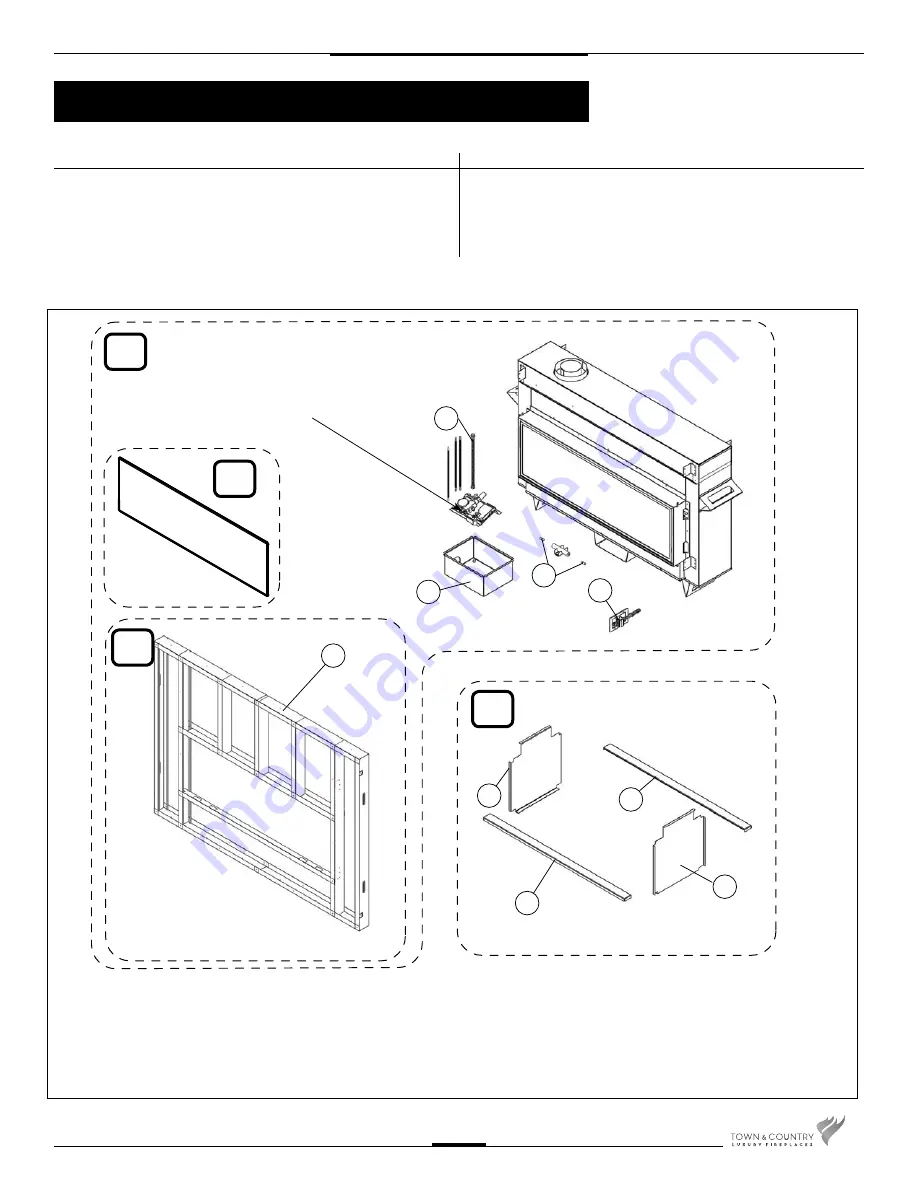

#1

#2

#3

#4

MAESTRO CONTROL ASSEMBLY - See Page 28

3a

4a

4b

4c

4d

1a

1b

6

7

61

TCWS.54CSTE 110712-72

Replacement Parts - TCWS.54CSTE

Summary of Contents for TCWS54ST SERIES D

Page 70: ...70 TCWS 54CSTE 110712 72 ...