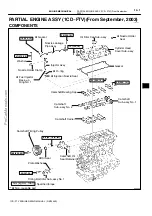

A56704

Seal Width

4 to 7 mm

B

A

A

B

(0.16 to 0.28 in.)

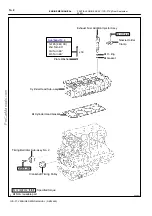

A57100

Protrusion Height

Measuring Tip

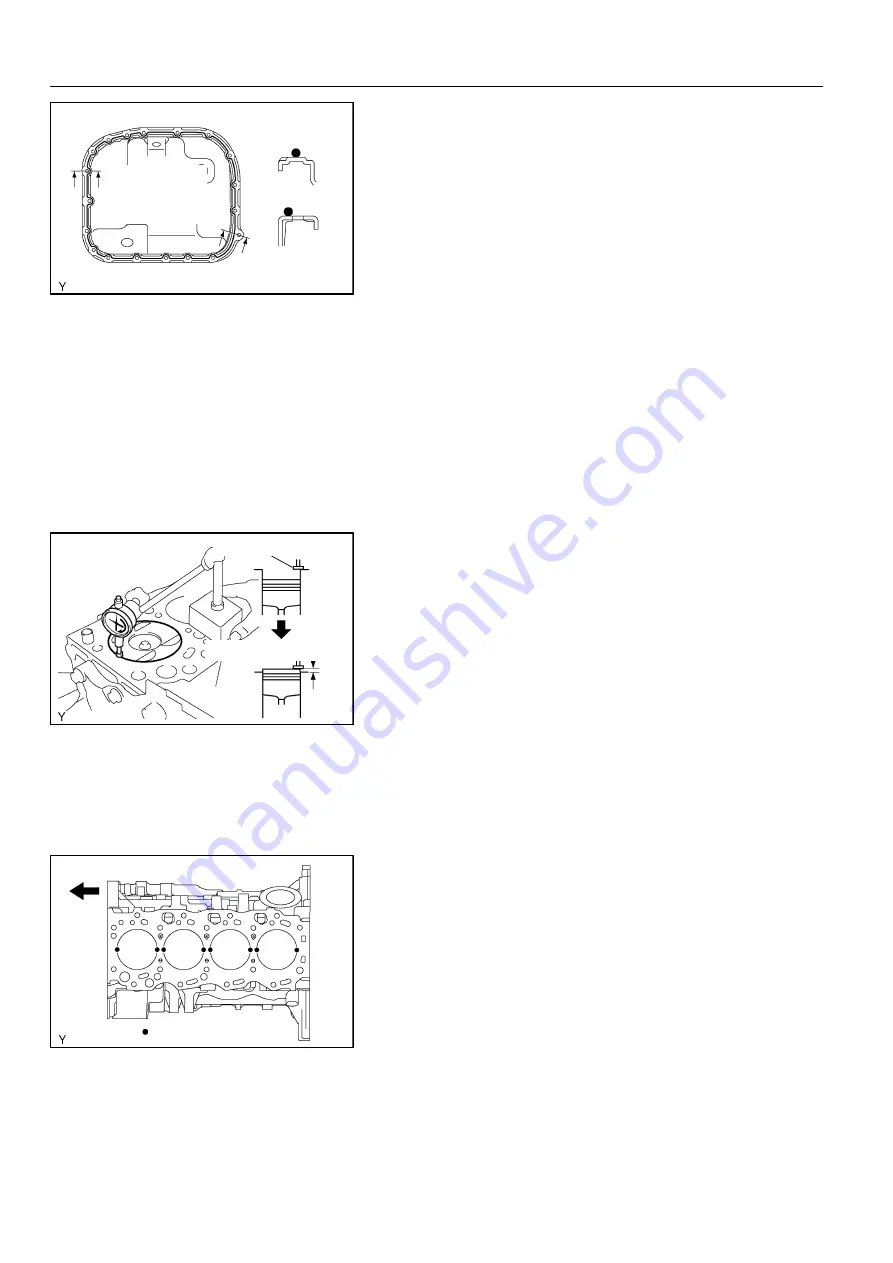

A56706

Front

Measuring Point

14

−

14

−

ENGINE MECHANICAL

PARTIAL ENGINE ASSY (1CD

−

FTV)(From September,

2003)

1CD

−

FTV ENGINE REPAIR MANUAL (RM1046E)

40.

INSTALL OIL PAN SUB

−

ASSY NO.2

(a)

Apply seal packing to the oil pan as shown in the illustra-

tion.

Seal packing: Part No. 08826

−

00080 or equivalent

NOTICE:

S

Install a nozzle of which opening is cut to 4 to 7 mm

(0.16 to 0.28 in.).

S

The parts must be set within 3 minutes and must be

assembled within 15 minutes after applying seal

packing. Otherwise the material must be removed

and reapplied.

S

Immediately remove the nozzle from the tube, then re-

install the cap.

(b)

Install the oil pan with the 16 bolts and 3 nuts. Tighten the

bolts and nuts uniformly in several steps.

Torque: 12 N

×

m (119 kgf

×

cm, 9 ft

×

lbf)

41.

INSTALL CYLINDER HEAD SUB

−

ASSY

(a)

Measure the protrusion height of the piston heads.

(1)

Clean the cylinder block with solvent.

(2)

Set the piston to measure to slightly before the

TDC.

(3)

Place a dial indicator on the cylinder block, then cali-

brate the dial indicator at 0 mm (0 in.).

HINT:

S

Place the measuring tip of the dial indicator as shown in

the illustration.

S

Make sure that the measuring tip is square to the cylinder

block gasket and piston head when measuring.

(4)

Find the most overhung position of the piston head

by slowly turning the crankshaft clockwise and

counterclockwise.

(5)

Measure the protrusion height of the piston head for

each cylinder at 2 places as shown in the illustra-

tion. (Total of 8 measurements.)

(6)

Record the higher protrusion height of the 2 mea-

surements at each cylinder.