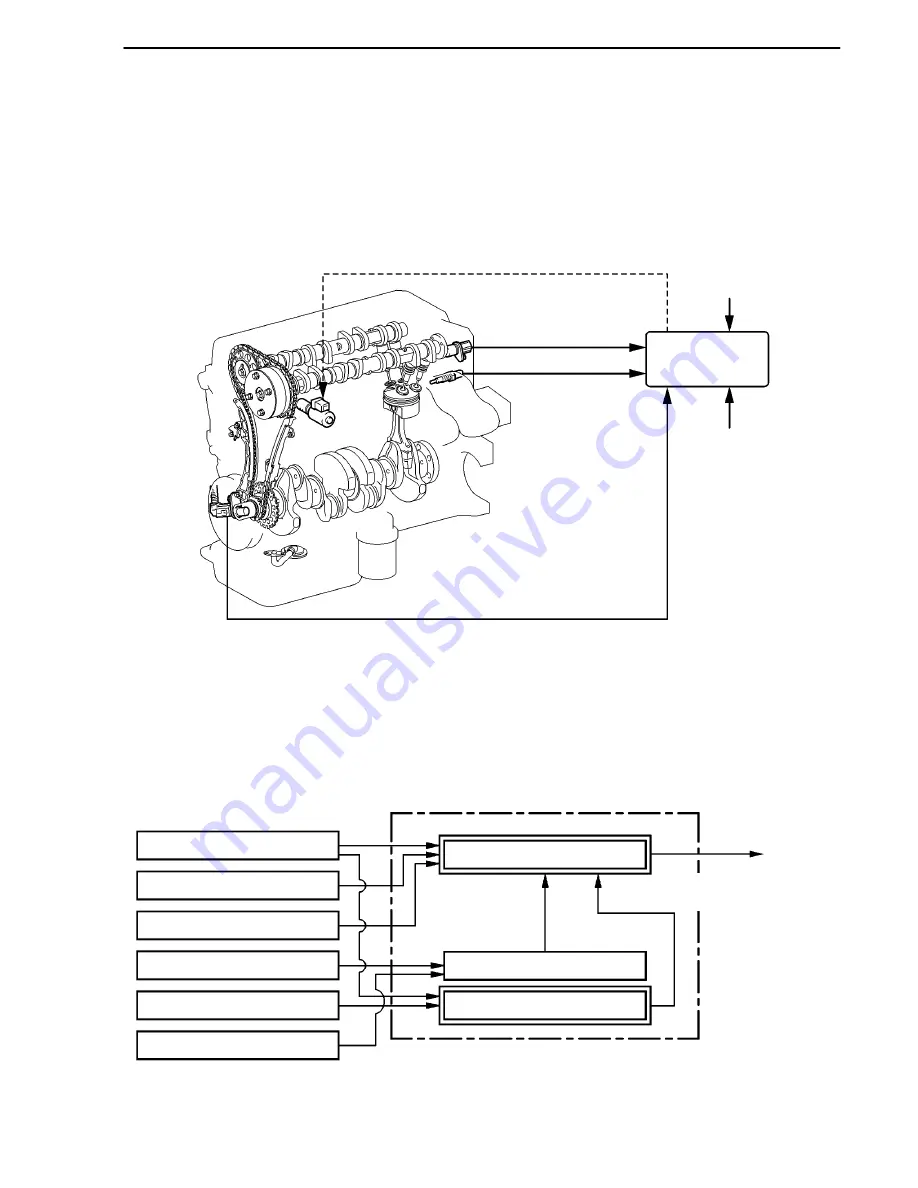

ENGINE - 1NZ-FE ENGINE

247EG23

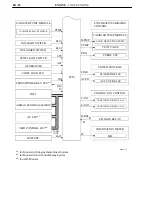

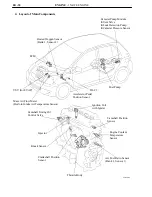

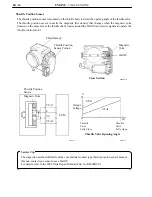

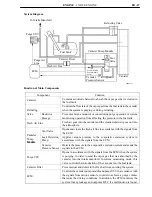

Camshaft Timing Oil Control Valve

Throttle Position

Sensor

Camshaft Position

Sensor

Engine Coolant

Temperature

Sensor

ECM

Mass Air

Flow Meter

Crankshaft Position Sensor

221EG16

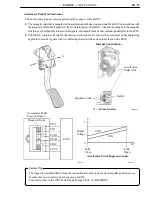

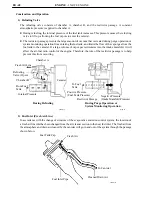

Crankshaft Position Sensor

Mass Air Flow Meter

Engine Coolant Temp. Sensor

Camshaft Position Sensor

Vehicle Speed Sensor

Throttle Position Sensor

Target Valve Timing

Duty-cycle

Control

Feedback

Correction

Actual Valve Timing

Camshaft

Timing

Oil

control

Valve

EG-41

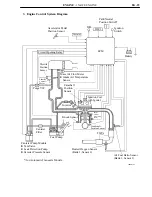

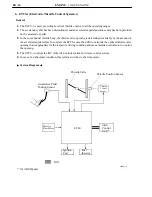

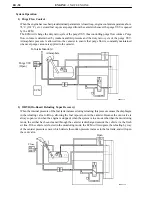

7. VVT-i (Variable Valve Timing-intelligent) System

General

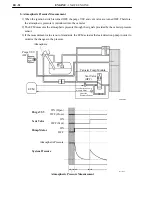

The VVT-i system is designed to control the intake camshaft within a range of 40

(of Crankshaft Angle)

to provide valve timing that is optimally suited to the engine condition. This realizes proper torque in

all the speed ranges as well as realizing excellent fuel economy, and reducing exhaust emissions.

Using the engine speed signal, vehicle speed signal, and the signals from mass air flow meter, throttle

position sensor and water temperature sensor, the engine ECU can calculate optimal valve timing for

each driving condition and controls the camshaft timing oil control valve. In addition, the engine ECU

uses signals from the camshaft position sensor and crankshaft position sensor to detect the actual valve

timing, thus providing feedback control to achieve the target valve timing.

Summary of Contents for 1NZ-FE

Page 59: ...EG 60 MEMO ...