P14632

P14645

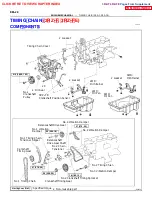

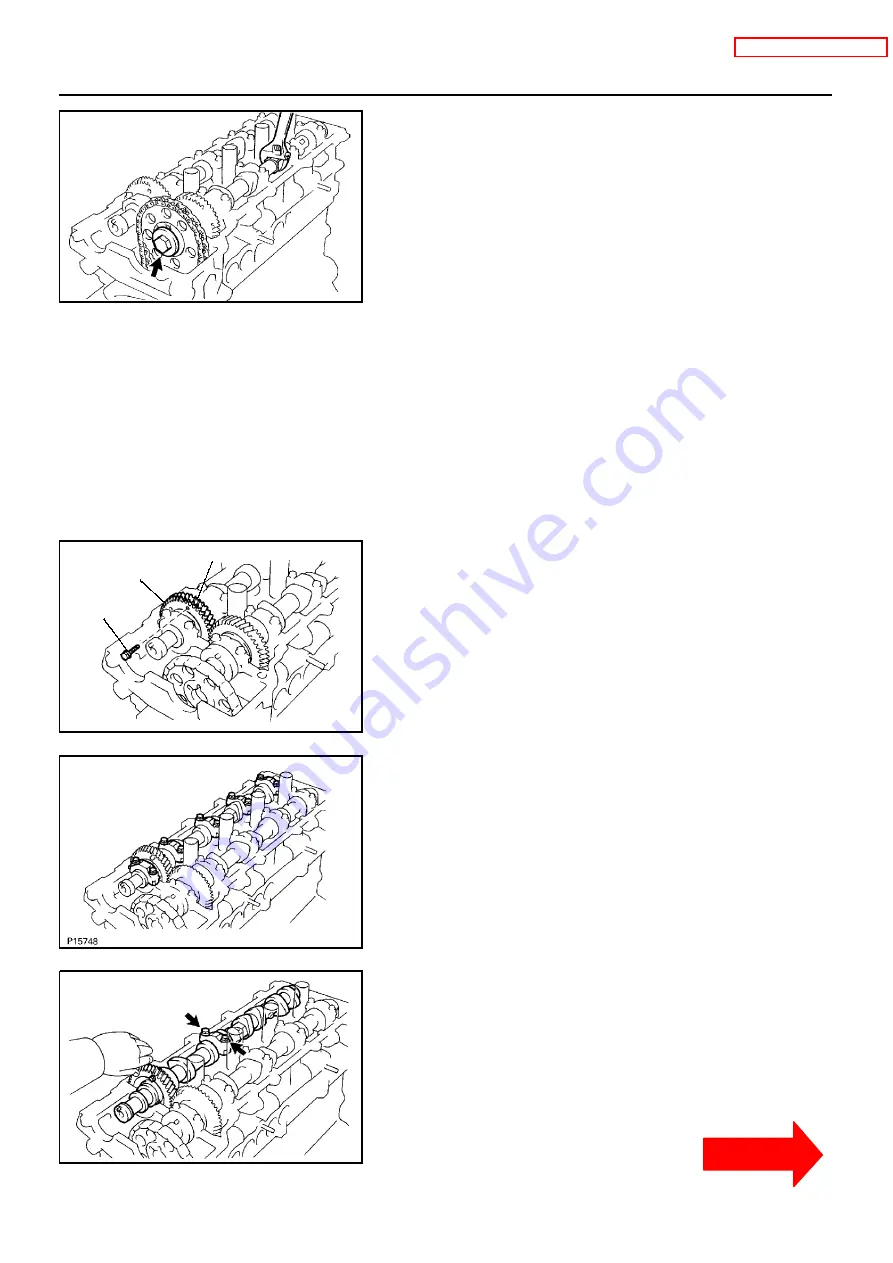

Main Gear

Sub Gear

Service

Bolt

Z11081

10

9

8

7

6

5

4

3

2

1

P14676

EM--38

--

ENGINE MECHANICAL

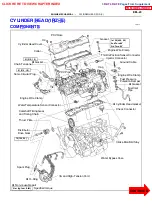

CYLINDER HEAD (2RZ--FE)

(b)

Hold the intake camshaft with a wrench and remove the

bolt.

(c)

Remove the camshaft timing gear and chain from the in-

take camshaft and leave on the slipper and damper.

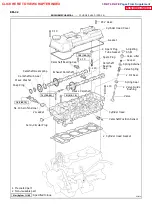

2 2 . RE MO V E CAMS HAFTS

NOTICE:

Since the thrust clearance of the camshaft is small, the

camshaft must be kept level while it is being removed. If the

camshaft is not kept level, the portion of the cylinder head

receiving the shaft thrust may crack or be damaged, caus-

ing the camshaft to seize or break. To avoid this, these

steps should be carried out.

(a)

Remove exhaust camshaft

(1)

Bring the service bolt hole of the driven sub--gear

upward by turning the hexagon wrench head por-

tion of the exhaust camshaft with a wrench.

(2)

Secure the exhaust camshaft sub--gear to the main

gear with a service bolt.

Recommended service bolt:

Thread diameter 6 mm

Thread pitch

1.0 mm

Bolt length

16 -- 20 mm (0.63 -- 0.79 in.)

HINT:

When removing the camshaft, make sure that the torsional

spring force of the sub--gear has been eliminated by the above

operation.

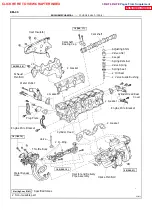

(3)

Uniformly loosen and remove the 10 bearing cap

bolts, in several passes, in the sequence shown.

(4)

Remove the 5 bearing caps and camshaft.

HINT:

If the camshaft is not being lifted out straight and level, reinstall

the No.3 bearing cap with the 2 bolts. Then alternately loosen

and remove the bearing cap bolts with the camshaft gear pulled

up.

NOTICE:

Do not pry on or attempt to force the camshaft with a tool

or other object.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE