P14774

P04615

Nut

90

˚

Painted Mark

P14810

Seal Packing

--

ENGINE MECHANICAL

CYLINDER BLOCK (2RZ--FE, 3RZ--F)

EM--81

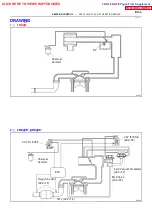

1 3 . I NS TALL CO NNE CTI NG RO D CAP NUTS

HINT:

S

The connecting rod cap nuts are tightened in 2 progres-

sive steps (steps (b) and (d)).

S

If any connecting rod bolt is broken or deformed, replace

it.

(a)

Apply a light coat of engine oil on the threads and under

the nuts of the connecting rod cap.

(b)

Install and alternately tighten the nuts of the connecting

rod cap in several passes.

Torque:

45 N

∙

m (460 kgf

∙

cm, 33 ft

∙

lbf)

If any one of the connecting rod cap nuts does not meet the

torque specification, replace the connecting rod bolt and cap

nut as a set.

(c)

Mark the front of the connecting rod cap nut and bolt with

paint.

(d)

Retighten the connecting rod cap nuts 90

˚

as shown.

(e)

Check that the painted mark on the nut is at a 90

˚

angle

in relation to the mark on the bolt.

(f)

Check that the crankshaft turns smoothly.

(g)

Check the connecting rod thrust clearance.

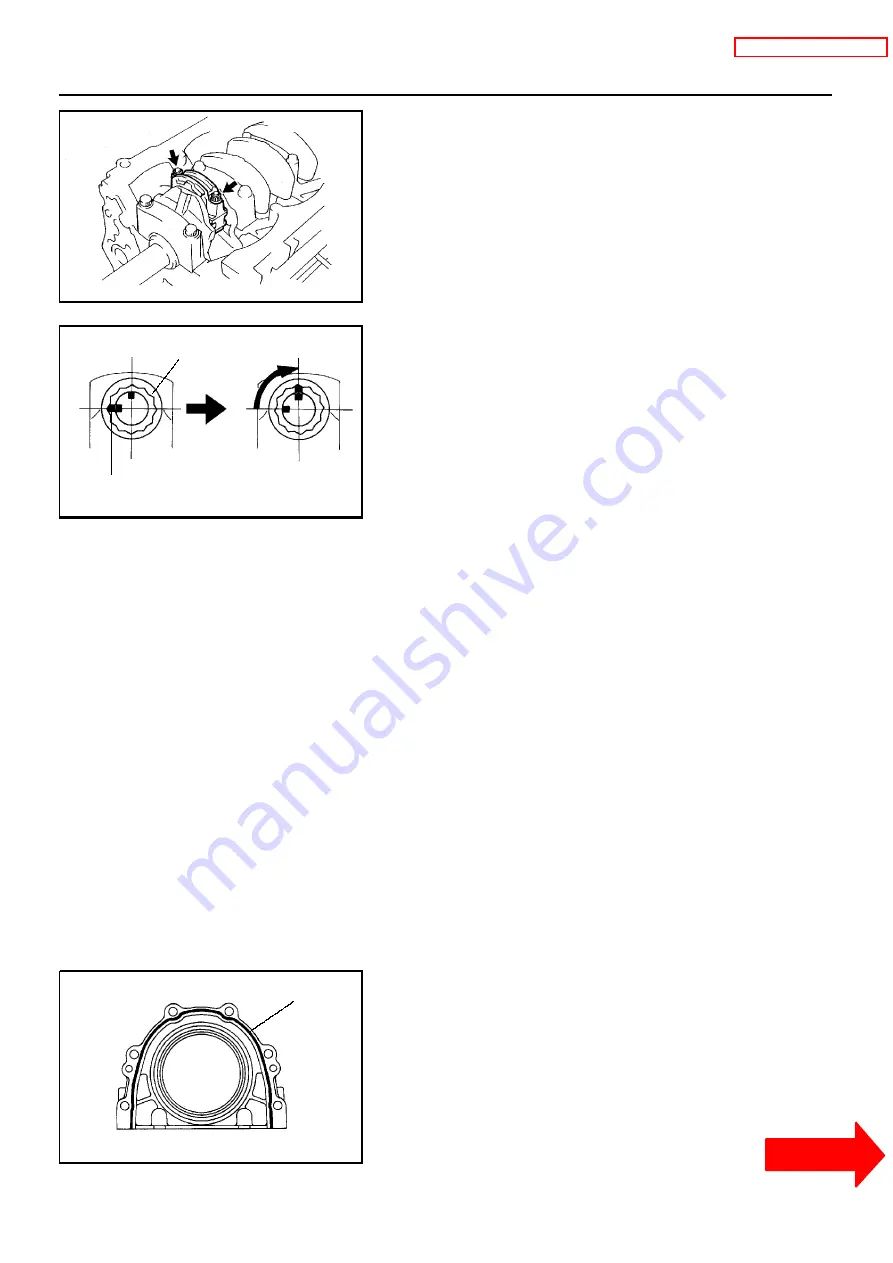

14. INSTALL REAR OIL SEAL RETAINER

(a)

Remove any old packing (FIPG) material and be careful

not to drop any oil on the contact surfaces of the retainer

and cylinder block.

S

Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket sur-

faces and sealing groove.

S

Thoroughly clean all components to remove all the

loose material.

S

Using a non--residue solvent, clean both sealing

surfaces.

(b)

Apply seal packing to the retainer as shown in the illustra-

tion.

Seal packing:

Part No. 08826--00080 or equivalent

S

Install a nozzle that has been cut to a 2 -- 3 mm (0.08

-- 0.12 in.) opening.

HINT:

Avoid applying an excessive amount to the surface.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE