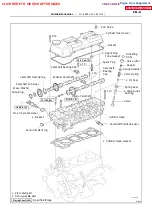

ENGINE MECHANICAL –

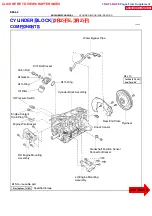

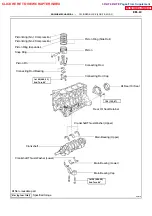

CYLINDER BLOCK (2RZ-FE, 3RZ-F)

PAGE 1 OF 2

DISASSEMLBY

1. REMOVE FLYWHEEL

3. INSTALL ENGINE TO ENGINE STAND FOR DISASSEMBLY

5. REMOVE TIMING CHAINS, GEARS AND SPROCKET

10. REMOVE ENGINE COOLANT DRAIN PLUG

11. REMOVE OIL PRESSURE SWITCH

12. REMOVE RH AND LH ENGINE MOUNTING ASSEMBLIES

13. REMOVE ENGINE WIRE BRACKET

14. REMOVE CRANKSHAFT POSITION SENSOR CONNECTOR BRACKET

15. REMOVE REAR OIL SEAL RETAINER

16. CHECK CONNECTING ROD THRUST CLEARANCE

17. REMOVE CONNECTING ROD CAPS AND CHECK OIL CLEARANCE

18. REMOVE PISTON AND CONNECTING ROD ASSEMBLIES

19. CHECK CRANKSHAFT THRUST CLEARANCE

20. REMOVE MAIN BEARING CAPS AND CHECK OIL CLEARANCE

22. CHECK FIT BETWEEN PISTON AND PISTON PIN

24. DISCONNECT CONNECTING ROD FROM PISTON

INSPECTION

1. REMOVE GASKET MATERIAL

3. INSPECT TOP SURFACE OF CYLINDER BLOCK FOR FLATNESS

4. INSPECT CYLINDER FOR VERTICAL SCRATCHES

5. INSPECT CYLINDER BORE DIAMETER

7. INSPECT MAIN BEARING CAPS BOLTS

9. INSPECT PISTON OIL CLEARANCE

10. INSPECT PISTON RING GROOVE CLEARANCE

11. INSPECT PISTON RING END GAP

13. INSPECT CONNECTING ROD ALIGNMENT

14. INSPECT PISTON PIN OIL CLEARANCE

15. IF NECESSARY, REPLACE CONNECTING ROD BUSHING

16. INSPECT CONNECTING ROD BOLTS

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE