A02827

Elongated

Measuring

Thread

Point

P14767

P14822

Z15298

--

ENGINE MECHANICAL

CYLINDER BLOCK (2RZ--FE, 3RZ--F)

EM--71

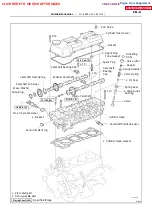

7. INSPECT MAIN BEARING CAP BOLTS

Using vernier calipers, measure the minimum diameter of the

elongated thread at the measuring point.

Standard outside diameter:

10.76 -- 10.97 mm (0.4236 -- 0.4319 in.)

Minimum outside diameter:

10.40 mm (0.4094 in.)

If the diameter is less than minimum, replace the bolt.

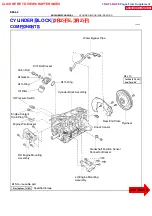

8. CLEAN PISTON

(a)

Using a gasket scraper, remove the carbon from the pis-

ton top.

(b)

Using a groove cleaning tool or broken ring, clean the pis-

ton ring grooves.

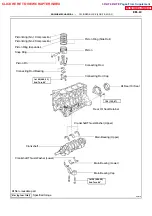

(c)

Using solvent and a brush, thoroughly clean the piston.

NOTICE:

Do not use a wire brush.

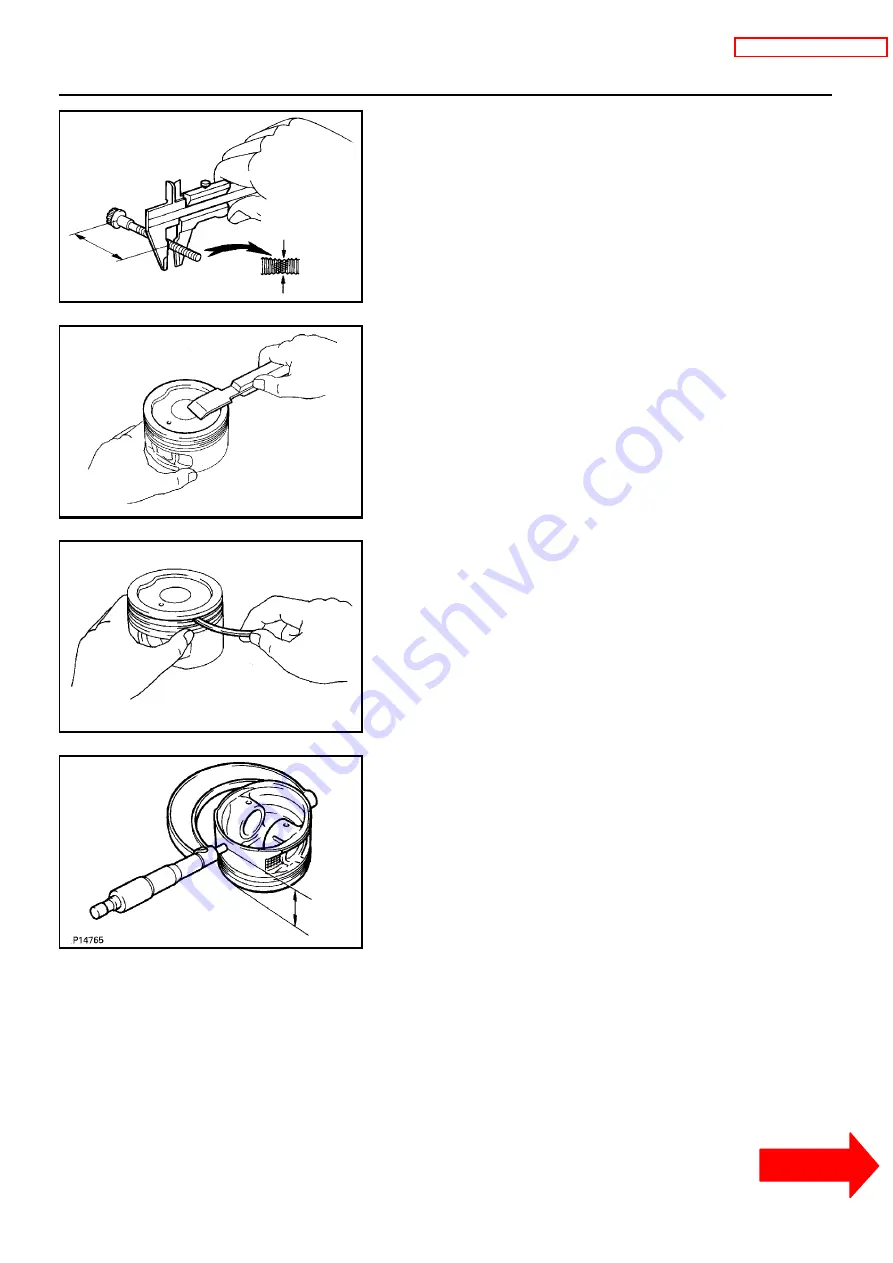

9. INSPECT PISTON OIL CLEARANCE

(a)

Using a micrometer, measure the piston diameter at right

angles to the piston pin center line, 35.5 mm (1.40 in.)

from the piston head.

Piston diameter:

STD

2RZ--FE: 94.923 -- 94.933 mm (3.7371 -- 3.7375 in.)

3RZ--F: 94.933 -- 94.943 mm (3.7375 -- 3.7379 in.)

O/S 0.50

2RZ--FE: 95.423 -- 95.433 mm (3.7568 -- 3.7572 in.)

3RZ--F: 95.433 -- 95.443 mm (3.7572 -- 3.7576 in)

(b)

Measure the cylinder bore diameter in the thrust direc-

tions.

(c)

Subtract the piston diameter measurement from the cylin-

der bore diameter measurement.

Standard oil clearance:

2RZ--FE: 0.057 -- 0.080 mm (0.0022 -- 0.0031 in.)

3RZ--F: 0.047 -- 0.070 mm (0.0019 -- 0.0028 in.)

If the oil clearance is greater than maximum, replace all the 4

pistons and rebore all the 4 cylinders. If necessary, replace the

cylinder block.

HINT:(Use new cylinder block): Use a piston with the same

number mark as the cylinder bore diameter marked on the cylin-

der block.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE