13. INSTALL GENERATOR ADJUSTING BAR

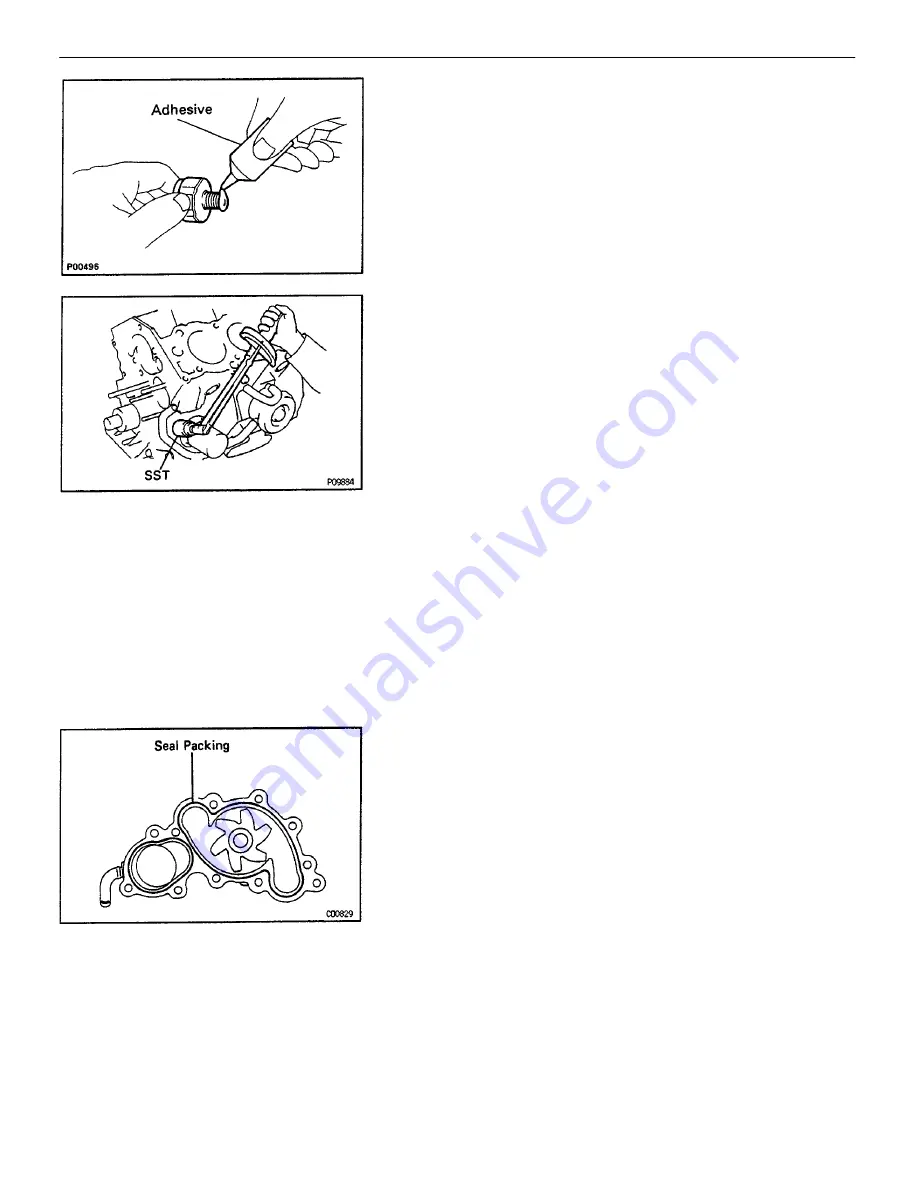

14. INSTALL WATER PUMP

(a) . Remove any old packing (FIPG) material and be car–

eful not to drop any oil on the contact surfaces of the

water pump and cylinder block.

•

Using a razor blade and gasket scraper, remove

all the old packing (FIPG) material from the

gasket surfaces and sealing groove.

•

Thoroughly clean all components to remove all

the loose material.

•

Using a non–residue solvent, clean both sealing

surfaces.

(b) Apply seal packing to the sealing groove of the water

pump as shown in the illustration.

Seal packing:

Part No. 08826–00100 or equivalent

•

Install a nozzle that has been cut to a 2 – 3 mm

(0.08 – 0.12 in.) opening.

•

Parts must be assembled within 5 minutes of

application. Otherwise the material must be re–

moved and reapplied.

•

Immediately remove nozzle from the tube and

reinstall cap.

12. INSTALL OIL PRESSURE SENDER GAUGE

(a) Apply adhesive to two or three threads.

Adhesive:

Part No.08833–00080, THREE BOND 1344,

LOCTITE 242 or equivalent

(b) Using SST, install the oil pressure sender gauge.

SST 09816–30010

Torque: 15 N–m (150 kgf–cm. 11 ft–lbf)

–

ENGINE

ENGINE MECHANICAL

EG2–127

Summary of Contents for 22R-E

Page 1: ...INTRODUCTION INTRODUCTION IN 1 ...

Page 9: ...VEHICLE LIFT AND SUPPORT LOCATIONS INTRODUCTION VEHICLE LIFT AND SUPPORT LOCATIONS IN 9 ...

Page 35: ...22R E ENGINE ENGINE EG1 1 ...

Page 45: ...HINT Adjust idle mixture as necessary ENGINE ENGINE MECHANICAL EG1 11 ...

Page 49: ...CYLINDER HEAD COMPONENTS ENGINE ENGINE MECHANICAL EG1 15 ...

Page 80: ...CYLINDER BLOCK COMPONENTS ENGINE ENGINE MECHANICAL EG1 46 ...

Page 110: ...EXHAUST SYSTEM COMPONENTS ENGINE ENGINE MECHANICAL EG1 76 ...

Page 116: ...LAYOUT AND SCHEMATIC DRAWING Federal and Canada ENGINE EMISSION CONTROL SYSTEMS EG1 82 ...

Page 117: ...LAYOUT AND SCHEMATIC DRAWING Calif ENGINE EMISSION CONTROL SYSTEMS EG1 83 ...

Page 118: ...POSITIVE CRANKCASE VENTILATION PCV SYSTEM ENGINE EMISSION CONTROL SYSTEMS EG1 84 ...

Page 126: ...EXHAUST GAS RECIRCULATION EGR SYSTEM Calif ENGINE EMISSION CONTROL SYSTEMS EG1 92 ...

Page 135: ...MFI SYSTEM DESCRIPTION ENGINE MFI SYSTEM EG1 101 ...

Page 211: ...FUEL PUMP ENGINE MFI SYSTEM EG1 177 ...

Page 226: ...FUEL TANK AND LINE COMPONENTS ENGINE MFI SYSTEM EG1 192 ...

Page 230: ...3 INSTALL INTAKE AIR CONNECTOR ENGINE MFI SYSTEM EG1 196 ...

Page 239: ...2 INSTALL THROTTLE BODY See page EG1 202 ELECTRONIC PARTS LOCATION ENGINE MFI SYSTEM EG1 205 ...

Page 278: ...3VZ E ENGINE ENGINE EG2 1 ...

Page 299: ... ENGINE ENGINE MECHANICAL EG2 22 ...

Page 300: ... ENGINE ENGINE MECHANICAL EG2 23 ...

Page 326: ...CYLINDER HEAD COMPONENTS ENGINE ENGINE MECHANICAL EG2 49 ...

Page 327: ... ENGINE ENGINE MECHANICAL EG2 50 ...

Page 367: ...CYLINDER BLOCK COMPONENTS ENGINE ENGINE MECHANICAL EG2 90 ...

Page 411: ...EXHAUST SYSTEM ENGINE ENGINE MECHANICAL EG2 134 ...

Page 419: ...LAYOUT AND SCHEMATIC DRAWING ENGINE EMISSION CONTROL SYSTEMS EG2 142 ...

Page 435: ...MFI SYSTEM SYSTEM CIRCUIT DESCRIPTION ENGINE MFI SYSTEM EG2 158 ...

Page 476: ... ENGINE MFI SYSTEM EG2 199 ...

Page 497: ...INJECTOR COMPONENTS FOR REMOVAL AND INSTALLATION ENGINE MFI SYSTEM EG2 220 ...

Page 508: ...FUEL TANK AND LINE COMPONENTS ENGINE MFI SYSTEM EG2 231 ...

Page 521: ...ELECTRONIC PARTS LOCATION ENGINE MFI SYSTEM EG2 244 ...

Page 569: ...IGNITION SYSTEM IGNITION SYSTEM IG 1 ...

Page 596: ...STARTING SYSTEM STARTING SYSTEM ST 1 ...

Page 597: ...STARTER COMPONENTS STARTING SYSTEM Starter ST 2 ...

Page 609: ...CHARGING SYSTEM CHARGING SYSTEM CH 1 ...

Page 613: ...GENERATOR COMPONENTS CHARGING SYSTEM Generator CH 5 ...