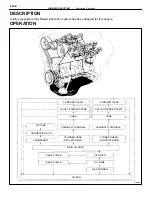

A Pressure feeding lubrication system has been adopted to supply oil to the moving parts of this engine.

The lubrication system consists of an oil pan, oil pump, oil filter and other external parts which supply oil to the

moving parts in the engine block. The oil circuit is shown in the illustration at the top of the previous page. Oil

from the oil pan is pumped up by the oil pump. After it passes through the oil filter, it is fed through the various

oil holes in the crankshaft and cylinder block. After passing through the cylinder block and performing its lubricat-

ing function, the oil is returned by gravity to the oil pan. A dipstick on the center left side of the cylinder block

is provided to check the oil level.

OIL PUMP

The oil pump pumps up oil from the oil pan and sends it under pressure to the various parts of the engine.

An oil strainer is mounted in front of the inlet to the oil pump. The oil pump itself is a trochoid type pump. inside

of which there is a drive rotor and a driven rotor. When the drive rotor rotates, the driven rotor rotates in the same

direction, and since the axis of the driven rotor shaft is different from the center of the driven rotor, the space

between the two rotors is changed as they rotate. Oil is drawn in when the space is wide and is discharged when

the space in narrow.

OIL PRESSURE REGULATOR

At high engine speeds, the engine oil supplied by the oil pump exceeds the capacity of the engine to utilize

it. For that reason, the oil pressure regulator works to prevent an oversupply of oil. During normal oil supply, a

coil spring and valve keep the bypass closed, but when too much oil is being fed, the pressure become extremely

high, overpowering the force of the spring and opening the valves. This allows the excess oil to flow through

the relief valve and return to the oil pan.

OIL FILTER

The oil filter is a full flow type filter with a built–in paper filter element. Particles of metal from wear, airborn

dirt, carbon and other impurities can get into the oil during use and could cause accelerated wear or sizing if

allowed to circulate through the engine. The oil filter, integrated into the oil line, removes these impurities as the

oil passes through it. The filter is mounted outside the engine to simplify replacement of the filter element. A relief

valve is also included ahead of the filter element to relieve the high oil pressure in case that the filter element

becomes clogged with impurities. The relief valve opens when the oil pressure overpowers the force of the

spring. Oil passing through the relief valve by–passes the oil filter and flows directly into the main oil hole in the

engine.

–

LUBRICATION SYSTEM

Operation

LU–3

Summary of Contents for 2VZ-FE

Page 1: ...ENGINE MECHANICAL EM 1 ENGINE MECHANICAL Description Operation ...

Page 31: ...CYLINDER HEADS COMPONENTS EM 29 ENGINE MECHANICAL Cylinder Heads ...

Page 63: ...CYLINDER BLOCK REMOVAL OF ENGINE EM 61 ENGINE MECHANICAL Cylinder Block ...

Page 64: ...EM 62 ENGINE MECHANICAL Cylinder Block ...

Page 71: ...COMPONENTS EM 69 ENGINE MECHANICAL Cylinder Block ...

Page 106: ...EFI SYSTEM FI 1 ...

Page 107: ...DESCRIPTION FI 2 EFI SYSTEM Description ...

Page 111: ...OPERATION System Circuit FI 4 EFI SYSTEM Operation System Circuit ...

Page 121: ...FUEL SYSTEM Fuel Pump EFI SYSTEM Fuel System Fuel Pump FI 15 ...

Page 141: ...Fuel Tank and Lines COMPONENTS EFI SYSTEM Fuel System Fuel Tank and Lines FI 35 ...

Page 172: ...EXHAUST SYSTEM EXHAUST SYSTEM REPAIR INSTRUCTIONS EX 1 ...

Page 174: ...EMISSION CONTROL SYSTEMS EC 1 ...

Page 186: ...COOLING SYSTEM CO 1 ...

Page 205: ...LUBRICATION SYSTEM LUBRICATION SYSTEM Description Operation LU 1 ...

Page 224: ...IGNITION SYSTEM IG 1 ...

Page 237: ...SERVICE SPECIFICATIONS IG 14 IGNITION SYSTEM ServiceSpecifications ...

Page 238: ...ENGINE TROUBLESHOOTING TR 1 ...