18 PLANNED MAINTENANCE

en‐79

18.3 PROTECT YOUR INVESTMENT WITH TOYOTA GENUINE

PARTS

Why gamble with your valuable assets? When your forklift needs periodic maintenance as

every forklift does you need Toyota Genuine Parts.

The same parts used on Toyota assembly lines meeting the same tough Toyota standards

for “PERFORMANCE”, “DURABILITY”, and “SAFETY”.

TOYOTA GENUINE PARTS

Offer Excellent Dustcatching Perform

ance on:

e.g. Air element, Torque converter oil filter,

Return oil filter, Engine oil filter Fuel filter

IF YOU USE A NONGENUINE ENGINE OIL

FILTER:

1.

Clogging may result, which can lead to

engine seizure.

2.

The engine oil may become dirty faster,

necessitating frequent oil changes.

3.

It can pass dirty oil to the engine, caus

ing engine wear.

TOYOTA GENUINE PARTS

TOYOTA GENUINE PARTS Offer Supreme

Durability on:

e.g. Clutch disc, Radiator hose, V belt

IF YOU USE A NONGENUINE RADIATOR

HOSE:

1.

The hose may wear out extremely rap

idly.

2.

The hose may be susceptible to water

leakage, necessitating frequent replace

ment.

TOYOTA GENUINE PARTS

Offer Added Safety on:

e.g. Lift roller, Lift chain, Tierod end, Brake

shoe

IF YOU USE A NONGENUINE BRAKE

SHOE:

1.

Braking performance may be excessive,

insufficient, or erratic, which is danger

ous.

2.

The brakes may drag. wasting fuel or

battery power.

Call your Toyota authorized shop for aftersale ser

vice

With high quality TOYOTA genuine parts and superior

service technology, Toyota helps keep customer's fork

lifts in the best condition for efficient work and higher

productivity. We deliver satisfaction to the customers

with Toyota genuine parts.

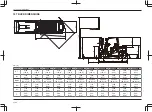

18.4 PERIODIC MAINTENANCE AND REPLACEMENT

Periodic inspection and maintenance are necessary to keep your Toyota industrial truck

running safely and smoothly. The maintenance experts at the Toyota dealer are specially

trained to use the right tools and approved procedures to protect the investment you have

made in this high quality truck. Do not entrust it to amateurs.

The designated numbers of hours in the inspection cycle are as follow:

Daily (preoperation check)

Every 8 hours

Weekly

Every 40 hours

Every 6 weeks

Every 250 hours

Every 3 months

Every 500 hours

Every 6 months

Every 1000 hours

Every 12 months

Every 2000 hours

If the operation time exceeds 250 hours within 6 weeks, use the number of hours as a guide

for performing periodic inspection. Preoperation checks and weekly inspections should

preferably be performed by the user. 6week, 3month, 6month and 12month inspections

should be performed by the Toyota dealer.

Refer to the Periodic Maintenance Table to determine the inspection and maintenance items

and inspection cycles.

Use only genuine Toyota parts for replacements, and always use the recommended types of

lubricants.

18.4.1 Periodic replacement of parts and lubricants

Replacement shall be made upon arrival of the operation hours or months, whichever is

earlier.

● : Replacement

*: Change the engine oil and oil filter of new trucks at 6 weeks or 250 hours of use.

Inspection Period

(Accumulated hours of operation

or monthly periods of operation,

whichever comes sooner.)

Every

6 weeks

Every

3 months

Every

6 months

Every

12 months

Item

Every

250 hours

Every

500 hours

Every

1000 hours

Every

2000 hours

Engine oil

●*

●

●

●

Engine oil filter

●*

●

●

●

Engine coolant except LLC (every 2

years for LLC)

●

●

●

Fuel filter

●

●

Torque converter oil

●

●

Torque converter oil filter

●

●

18

Summary of Contents for 40--8FD35N

Page 92: ...19 TRUCK DIMENSIONS en 93 19...