18 PLANNED MAINTENANCE

en‐80

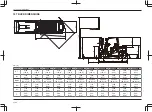

Inspection Period

(Accumulated hours of operation

or monthly periods of operation,

whichever comes sooner.)

Every

6 weeks

Every

3 months

Every

6 months

Every

12 months

Item

Every

250 hours

Every

500 hours

Every

1000 hours

Every

2000 hours

Differential gear oil

●

Planetary gear oil

●

Hydraulic oil

●

●

Hydraulic oil filter

●*

●

●

Wheel bearing grease

●

Spark plugs

●

●

Air cleaner element

●

Cups and seals for brake booster

and wheel cylinders

●

Power steering hoses

Every 2 years

Power steering rubbers parts

Every 2 years

Hydraulic hoses

Every 2 years

Fuel hoses

Every 2 years

Torque converter rubber hoses

Every 2 years

Oring for LPG tank valve (Option)

Every 2 years

LPG high and lowpressure rubber

hoses (Option)

Every 2 years

LPG regulator diaphragm and gas

ket, Oring (Option)

Every 2 years

LPG filter & shutoff valve dia

phragm and gasket (Option)

Every 2 years

Chains

Every 3 years

Timing belt of 1KD *

1

Every 4000 hours

Hydraulic oil pump seal

Every 3 years or 6000 hours

SAS Swing lock cylinder

Every 10000 hours

*

1

: The timing belt caution function will inform the operator when the timing belt needs to be

replaced. Refer to the INSTRUMENT chapter of this manual for details.

NOTICE! In case of the harsh or severe operating condition, the service interval of 170

hours or 1 month may be recommended.

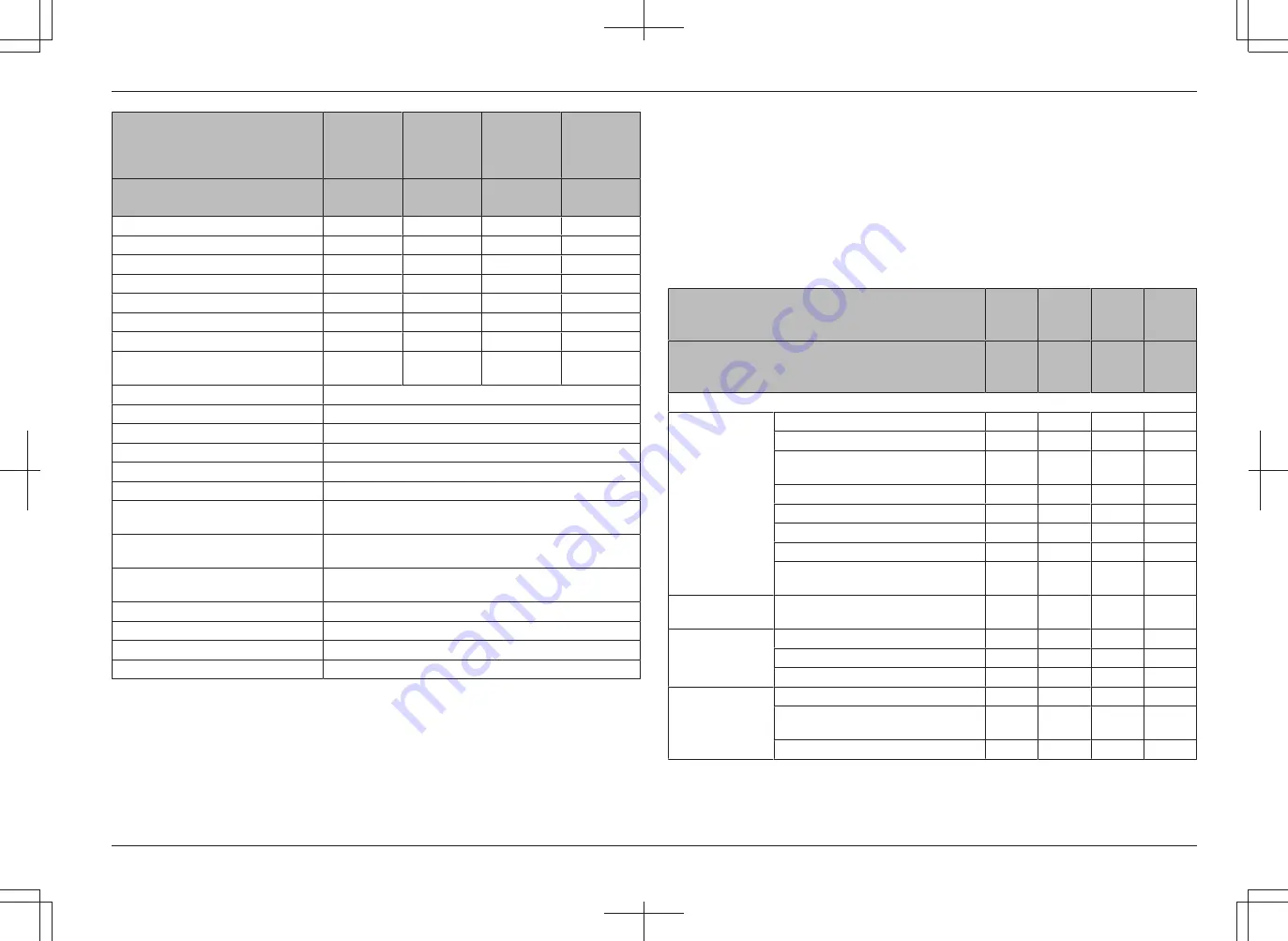

18.4.2 Periodic maintenance table

INSPECTION METHOD

I : Inspection. Repair or replacement if required.

M : Measurement. Repair or adjustment if required.

T : Retightening

C : Cleaning

L : Lubrication

*: Same as the left column

*

1

: For new truck

*

2

: Fissure and crack detector

Inspection Period

(Based on operating hours or months, whichever is

soonest.)

Every

6

weeks

Every

3

months

Every

6

months

Every

12

months

Item

Every

250

hours

Every

500

hours

Every

1000

hours

Every

2000

hours

ENGINE

Basic

compon

ents

Proper starting and abnormal noise

I*

1

I

*

*

Rotating condition at idling

M*

1

M

*

*

Rotating condition during accelera

tion

M*

1

M

*

*

Exhaust gas condition

I*

1

I

*

*

Air cleaner element

C*

1

C

*

*

Valve clearance

M*

1

M

Muffler rubber mount

I

Engine ancillary drive belt tension,

looseness and damage

I

*

*

*

PCV system

Clogging and damage in PCV valve

and piping

I*

1

I

*

*

Lubrication

sys

tem

Oil leak

I*

1

I

*

*

Oil level

I*

1

I

*

*

Clogging and dirt of oil filter

I

*

*

Fuel system

Fuel leak

I*

1

I

*

*

Dirt and clogging of fuel filter ele

ment

I

*

*

Draining of sedimenter

I

*

Summary of Contents for 40--8FD35N

Page 92: ...19 TRUCK DIMENSIONS en 93 19...