1-8

Structure

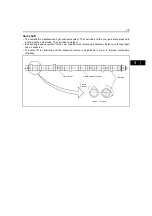

• The flame-proof resin that is light and oil resistant is used for the main body of the closed ventilator. For

the oil separate part, element-less type, which is maintenance-free, is adopted.

• To separate the oil mist in the blowby gas, there is a slewing part for the centrifugation and a filtering

part for crash and separation inside. Also there is a PCV valve to adjust the inner pressure of the

crankcase.

• On the body side, there are two ports. The upper port is for pumping out, linking to the intake-pipe, and

the lower port is for intaking the blowby of the engine. Also on the under side of the body, there is a port

to separate the oil mist included in the blowby gas and drain the liquefied oil.

• Concerning operation, when engine starts, negative pressure is generated in the intake-pipe, and the

PCV valve sucks the blowby gas in the intake-pipe with adjusting the pressure inside the crankcase. At

this time, the oil mist in the blowby gas is liquefied through centrifugation with slewing and crash and

separation with filtering, and is returned to the oil pan.

Blowby gas

Oil drain

Blowby gas flow

Filtering

PCV valve

インテーク

Revolving part