2-14

2 STEERING

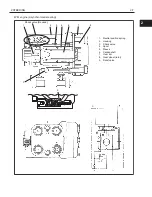

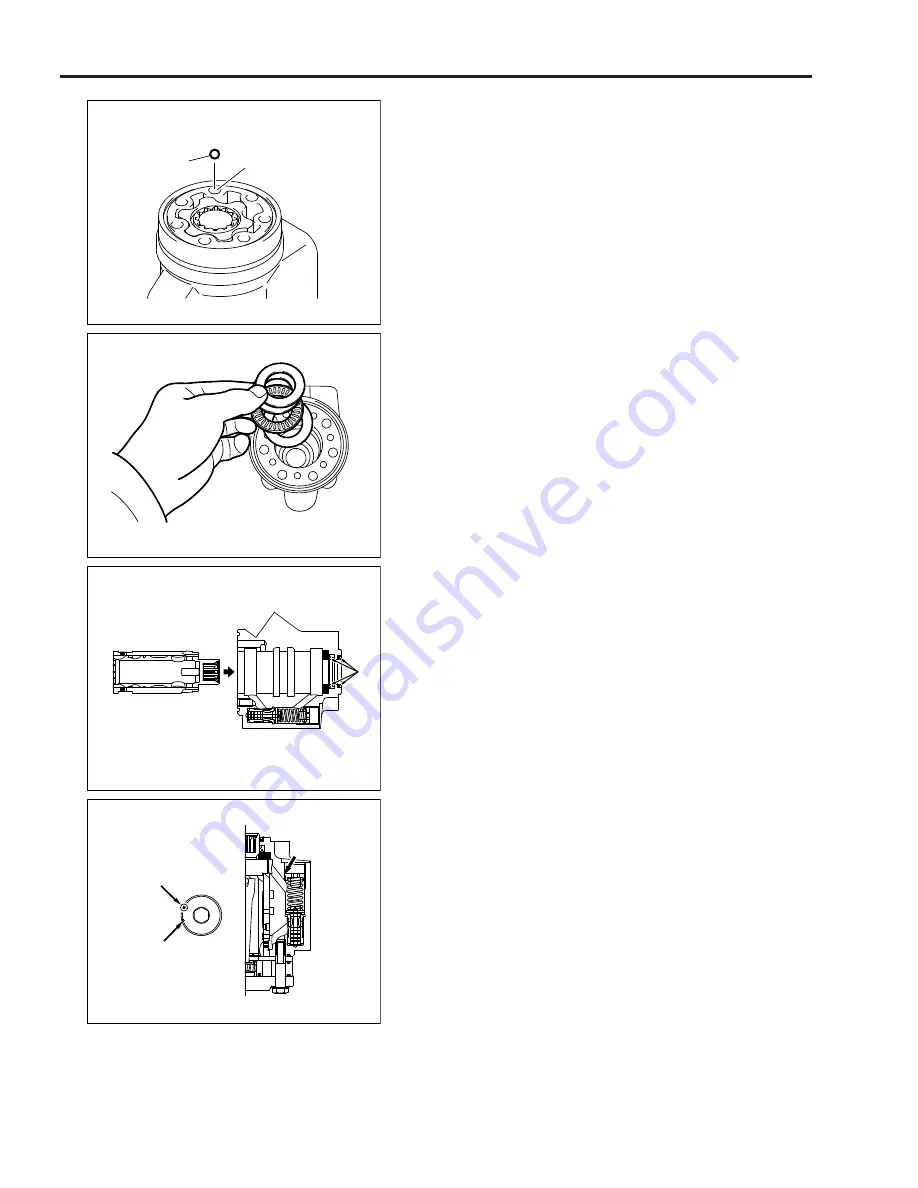

a

A

Point 3

Disassembly:

A steel ball is placed in portion A of the valve body.

Keep it so as not to be lost.

Reassembly:

Make sure to put the steel ball in portion A.

a: Steel ball

Point 4

Reassembly:

Install the retaining bearing as illustrated at left.

Install one plate, the thrust bearing, and two plates in

this order from the depth.

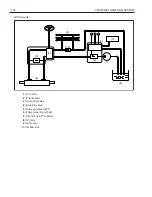

Reassembly:

When inserting the sleeve W/ spool into the valve

body, apply MP grease to the packing, ring inner sur-

face (portion in sliding contact with the spool), and

dust seal lip.

a

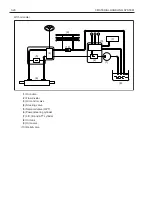

Point 5

Disassembly:

Measure the screwed-in depth of the adjust plug

(depth to the plug end face), and record it on a

memo.

Reassembly:

Refer to the memo for the adjust plug screwed-in

depth.

Reassembly:

Caulk two places on the circumference of the adjust

plug after hydraulic pressure adjustment.

a: Caulk

Summary of Contents for 62-8FDU15

Page 5: ...1 3 1 GENERAL 1 2 FRAME NUMBER Frame No Punching Position Punching position 1...

Page 8: ...2 6 2 STEERING 4YM and 1DZ engine W synchronized steering B B A A B B C C C C...

Page 11: ...2 9 2 STEERING 2 3 COMPONENTS 1ZS and 4YE engine 4507 4YM and 1DZ II engine 4507 2...

Page 13: ...2 11 2 STEERING 4YM and 1DZ II engine W synchronized steering 4503 2...

Page 23: ...3 21 3 MATERIAL HANDLING SYSTEM 3 2 COMPONENTS 6801 3...

Page 46: ...5 44 5 OIL CONTROL VALVE 5 2 3 COMPONENTS 1ZS and 4YE engine ASSY FITTING 6705...

Page 55: ...6 53 6 SAS OPS 6...

Page 56: ...6 54 6 SAS OPS Load Sensor 1DZ II engine 5803...

Page 157: ...8 155 8 TROUBLESHOOTING 8 3 WHEN NO ERROR CODE IS DISPLAYED Defect causes related to SAS OPS 8...

Page 191: ...8 189 8 TROUBLESHOOTING 8 4 WHEN ERROR CODE IS DISPLAYED 8...

Page 221: ...Published by 1st Printing Mar 2016 Pub No CE118 Printed in USA...

Page 222: ...PRINTED IN USA Pub No CE118...