5-35

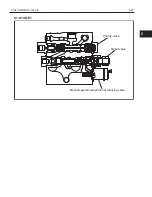

5 OIL CONTROL VALVE

2

1

4

3

Point 3

Inspection:

Check the lift limit switch for continuity.

Lowering side (measurement terminal 1

⇔

2):

No continuity when the switch is pressed.

Lifting side (measurement terminal 3

⇔

4):

No continuity when the switch is pressed.

Reassembly:

Be careful not to mistake the lowering side and lifting

side.

SST

Washer

Point 4

Disassembly and Reassembly:

Remove the compression spring from the lift spool.

SST 09610-10161-71

Use the SST after attaching a washer.

Point 5

Inspection:

Check the tilt solenoid for continuity.

(Reference)

Resistance: 9.4 to 10.4 Ω (at 20 °C)

Inspection:

Check and clean any clogged filter.

5

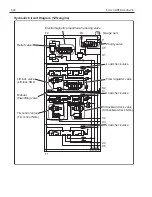

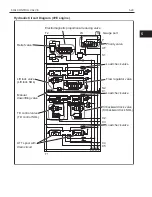

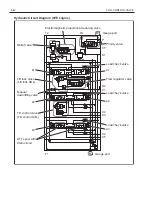

Summary of Contents for 62-8FDU15

Page 5: ...1 3 1 GENERAL 1 2 FRAME NUMBER Frame No Punching Position Punching position 1...

Page 8: ...2 6 2 STEERING 4YM and 1DZ engine W synchronized steering B B A A B B C C C C...

Page 11: ...2 9 2 STEERING 2 3 COMPONENTS 1ZS and 4YE engine 4507 4YM and 1DZ II engine 4507 2...

Page 13: ...2 11 2 STEERING 4YM and 1DZ II engine W synchronized steering 4503 2...

Page 23: ...3 21 3 MATERIAL HANDLING SYSTEM 3 2 COMPONENTS 6801 3...

Page 46: ...5 44 5 OIL CONTROL VALVE 5 2 3 COMPONENTS 1ZS and 4YE engine ASSY FITTING 6705...

Page 55: ...6 53 6 SAS OPS 6...

Page 56: ...6 54 6 SAS OPS Load Sensor 1DZ II engine 5803...

Page 157: ...8 155 8 TROUBLESHOOTING 8 3 WHEN NO ERROR CODE IS DISPLAYED Defect causes related to SAS OPS 8...

Page 191: ...8 189 8 TROUBLESHOOTING 8 4 WHEN ERROR CODE IS DISPLAYED 8...

Page 221: ...Published by 1st Printing Mar 2016 Pub No CE118 Printed in USA...

Page 222: ...PRINTED IN USA Pub No CE118...