Good

Good examp

examples

les

Bad

Bad examp

examples

les

3-23

3-23

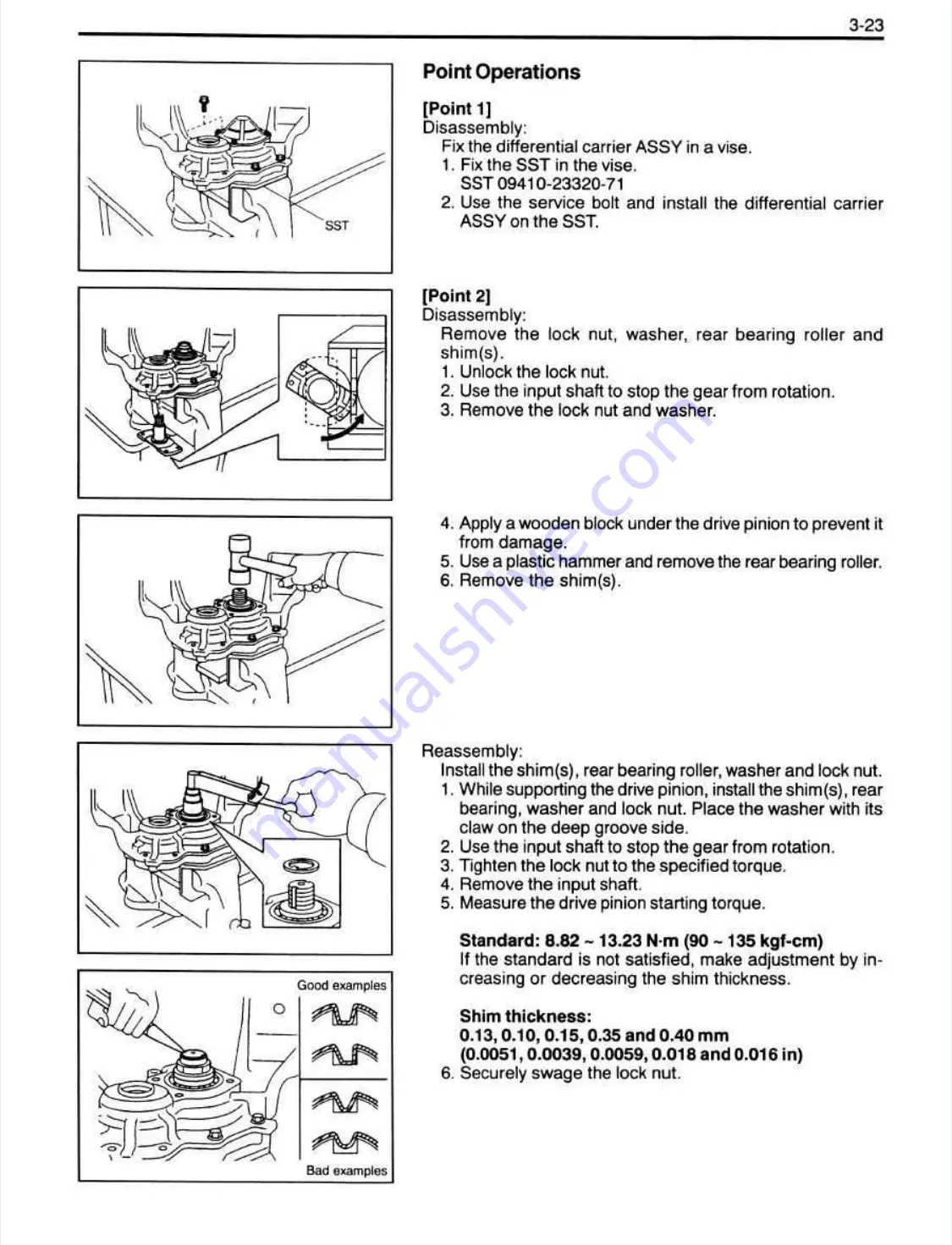

Point

Point Operat

Operations

ions

[Po

[Point

int 1]

1]

Disassembly:

Disassembly:

Fix

Fix the dif

the differ

ferent

ential

ial car

carrie

rier

r ASS

ASSY

Y in a

in a vis

vise.

e.

1. Fix

1. Fix the

the SST

SST in t

in the vise.

he vise.

SST 09410-23320-71

SST 09410-23320-71

2. U

2. Use the

se the se

serv

rvic

ice

e bo

bolt

lt an

and

d in

inst

stal

all l th

the

e di

diff

ffer

eren

enti

tial

al ca

carr

rrie

ier

r

ASSY

ASSY on

on the

the SST.

SST.

[Po

[Point

int 2]

2]

Disassembly:

Disassembly:

Re

Remo

move

ve th

the

e lo

lock

ck nu

nut, was

t, washe

her,

r, re

rear bea

ar beari

ring

ng ro

roll

ller

er an

and

d

shim(s).

shim(s).

1. Unl

1. Unlock the

ock the loc

lock

k nut

nut..

2. Use th

2. Use the

e inp

input

ut sha

shaft

ft to stop the

to stop the gea

gear

r fro

from

m rot

rotati

ation.

on.

3. Remo

3. Remove

ve the

the loc

lock

k nut an

nut and washe

d washer.

r.

4. Ap

4. Apply a wo

ply a woode

oden

n blo

block under the driv

ck under the drive

e pin

pinion to preve

ion to prevent

nt it

it

from

from damag

damage.

e.

5. Use a

5. Use a plast

plastic

ic hamme

hammer

r and remo

and remove

ve the rear bea

the rear bearing

ring rolle

roller.

r.

6. Rem

6. Remove

ove the

the shi

shim(s

m(s).

).

Reassembly:

Reassembly:

Ins

Instal

tall the shim(

l the shim(s),

s), rea

rear bear

r bearing

ing rol

roller

ler, wash

, washer

er and

and loc

lock

k nut

nut..

1.

1. Whil

While

e suppo

supporting

rting the driv

the drive pinion,

e pinion, insta

install th

ll the shim

e shim(s),

(s), rear

rear

bea

bearin

ring,

g, was

washer

her and lo

and lock nut. Plac

ck nut. Place the was

e the washer

her wit

with

h its

its

cla

claw on the

w on the dee

deep

p gro

groove

ove sid

side.

e.

2. Use t

2. Use the

he inp

input

ut sha

shaft

ft to sto

to stop

p the gear

the gear fro

from

m rot

rotati

ation.

on.

3. Tig

3. Tighte

hten

n the

the loc

lock

k nut

nut to the spec

to the specifi

ified

ed tor

torque

que..

4. Remo

4. Remove

ve the

the inp

input

ut sha

shaft.

ft.

5. Meas

5. Measure

ure the drive

the drive pinio

pinion startin

n starting

g torqu

torque.

e.

Standard:

Standard:

8.82

8.82 -13.2

-13.23

3

N·m

N·m

(90 -135

(90 -135

kgf-cm)

kgf-cm)

If

If th

the

e st

stan

anda

dard

rd is no

is not sat

t satis

isfi

fied

ed,

, ma

make

ke ad

adju

just

stme

ment

nt by in

by in--

cre

creasi

asing

ng or decr

or decreas

easing

ing the shim

the shim thi

thickn

ckness

ess..

Shim thickness:

Shim thickness:

0.13, 0.10, 0.15, 0.35

0.13, 0.10, 0.15, 0.35

and

and

0.40

0.40

mm

mm

(0.00

(0.0051, 0.0

51, 0.0039,

039, 0.005

0.0059, 0.018

9, 0.018 and

and 0.01

0.016

6 in)

in)

6. S

6. Secu

ecurel

rely

y swa

swage

ge the lock nut.

the lock nut.

https://www.besttruckmanuals.com/