Connecting the refrigerant pipe

Wrench

Indoor unit tubing

Open-end wrench (fixed)

Connection pipe

Flare nut

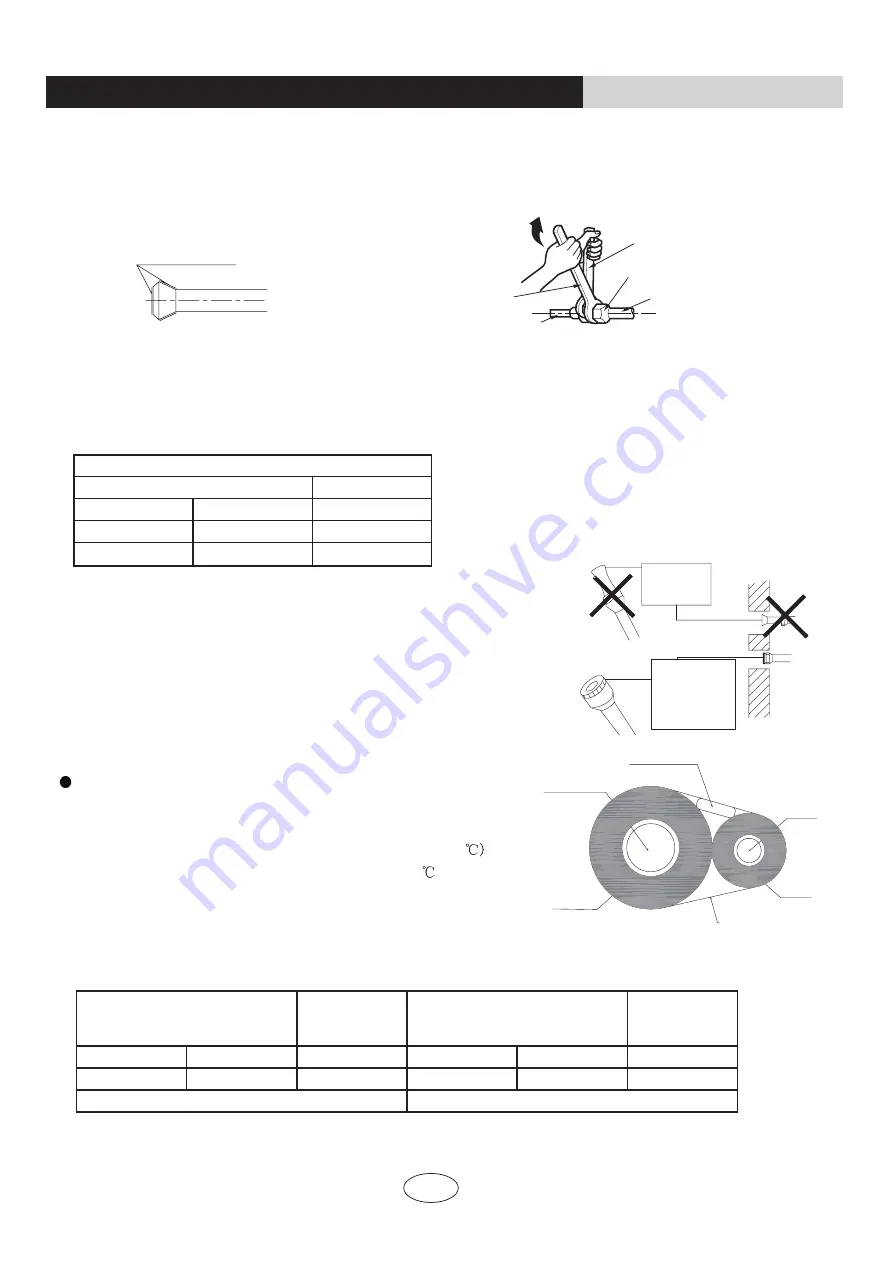

1) Use torque wrenches when tightening the flare nuts to prevent damage to the flare nuts and gas leaks.

Coat here with refrigeration oil

2) Align the centres of both flares and tighten the flares and tighten the flare nuts 3 or 4 turns by hand.

Then tighten them fully with the torque wrenches.

3) To prevent gas leakage, apply refrigeration oil on both inner and outer surfaces in the flare. (Use refrigeration oil for

R410A.)

Liquid side

09K/12K

18K

09K/12K/18K

3/8 inch

1/2 inch

1/4 inch

31-35 N.m

50-55 N.m

15-20 N.m

Flare nut tightening torque

Gas side

Gas side

Gas

pipe thermal insulation

Caution on piping handling

1)Protect the open end of the pipe against dust and moisture.

2)All pipe bends should be as gentle as possible. Use a pipe bender for

bending.

(Bending radius should be 30 to 40mm or larger.)

Gas pipe

Gas pipe

insulstion

Finising tape

Inter-unit wiring

Liquid pipe

Liquid pipe

insulation

Selection of copper and heat insulation materials

When using commercial copper pipes and fittings, observe the

following:

1)Insulation material: Polyethylene foam

Heat transfer rate:0.041 to 0.052W/mK(0.035 to 0.045kca/(mh

Refrigerant gas pipe’s surface temperature reaches 110 max.

Choose heat insulation materials that will withstand this temperature.

2)Be sure to insulate both the gas and liquid piping and to provide insulation dimensions as below.

Liquid side

Liquid pipe

thermal insulation

18K

18K

09K/12K

09K/12K

Thickness 0.8mm

Thickness 10mm Min.

O.D. 9.5mm

O.D. 12.7mm

O.D. 6.4mm

I.D. 12-15mm

I.D. 14-16mm

I.D. 8-10mm

3)Use separate thermal insulation pipes for gas and liquid refrigerant pipes.

Be sure to

place a cap.

If no flare cap is

available,cover

the flare mouth

with tape to keep

dirt or water out.

INSTALLATION INSTRUCTIONS

Installation of indoor unit

2

5